FT-901

FL-170/180/200

FH-260

FT-305

Description

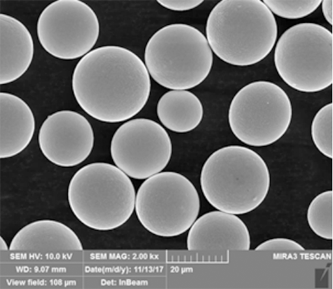

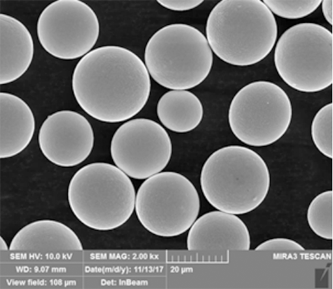

SnSb10 alloy solder powder with excellent sphericity, uniform particle size, and low oxygen content is mixed with no-clean flux to produce FTP-901/FTD-901 series solder paste based on metallurgical method and chemical structure. It has an outstanding adhesion effect before soldering. Solvent volatilizes very slightly during soldering. Moreover, the solder paste has extraordinary wettability, anti-slump, and residue reduction properties. It is developed to meet the market demand for heat-resistant microelectronic device assembly and precision soldering. FTP-901/FTD-901 has a superior heat resistance and heat dissipation performance. It also improves the soldering voiding and the strength and conductivity of intermetallic compounds.

Features

1. FT-901 has extraordinary thermal conductivity, electrical conductivity, and soldering strength;

2. Special ultra-fine solder powder satisfies high-power chip soldering with a size exceeding 20mil;

3. The operation is simple. Reflow oven, electric hot plate, and stove can be used;

4. It has advantages such as outstanding thixotropy, appropriate viscosity, excellent stability, no delamination, and long operating life;

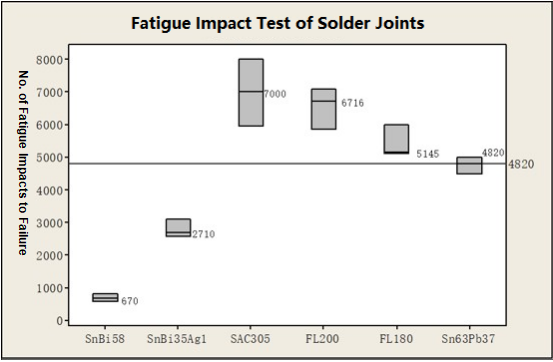

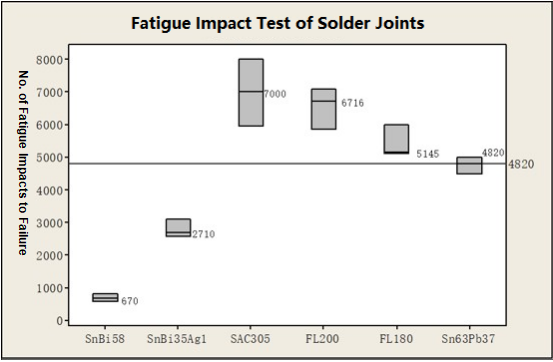

5. The creep resistance of FT-901 is extraordinary, and it has heat resistance better than that of SAC305 alloy.

Description

FL170 is a low-temperature alloy solder powder with excellent sphericity, uniform particle size, low oxygen content, and high strength. It is combined with zero-halogen flux to produce FL-170 series low-temperature solder paste. Only a tiny amount of solvent volatilizes during the soldering process. There is no solder ball generation after soldering. The solder paste has outstanding residue minimization and wettability. The solder joints generated are solid, plump, and bright. FL-170 is ideal for low-temperature soldering, especially for low-temperature component mounting.

Features

1. Excellent soldering strength with a peak reflow temperature of 170℃;

2. Antimony-free, lead-free and environmental-friendly;

3. Outstanding thixotropy and appropriate viscosity available for jet printing, pin transfer, dispensing, printing, etc.;

4. Superior printing performance and stencil life because of stable viscosity and tack time over 12 hours;

5. Extraordinary soldering performance and proper wettability in different parts;

6. Less residue production after drying, no solder ball formation, and reliable solder joints.

Description

FH260 solder powder with excellent sphericity, uniform particle size, and low oxygen content is combined with halogen-free flux to produce FH-260 series solder paste. It is a high-temperature lead-free product developed for secondary reflow soldering of power semiconductor and microelectronic packaging. The alloy is synthesized based on bismuth elements by adding reinforced micro/nanoparticles, successfully replacing high-lead solder paste, and meeting RoHS environmental protection standards. FH-260P series and FH-260D series are adapted to printing and dispensing processes, respectively.

Features

1. FH260 is a lead-free antimony-free product exempt from RoHS;

2. It has excellent thixotropy, viscosity, wettability, and solderability;

3. It is achievable for high-density integrated circuit packaging and secondary reflow soldering of circuit boards;

4. The use of ultra-fine powder improves ultra-fine-pitch and micro-assembly printing performance;

5. It is a no-clean halogen-free product that only produces a tiny amount of residue.

Description

Fitech produces SAC305 solder powder with excellent sphericity, uniform particle size, and low oxygen content, and it is mixed with halogen-free flux to prepare FTP-305/FTD-305 series solder paste. The solder paste has a superior adhesion effect before soldering. Solvent volatilizes very slightly during soldering. Moreover, the solder paste has extraordinary wettability, anti-slump, and residue reduction properties. There is no solder ball formation during soldering. It is an ideal soldering material for micro-bump ultra-fine-pitch packaging.

Features

1. FTP-305/FTD-305 has better thermal conductivity and electrical conductivity than that of silver conductive adhesive;

2. The ultra-fine solder powder has narrow size distribution. FTP-305/FTD-305 has stable solder paste printing and outstanding anti-slump performance, and it is suitable for ultra-fine-pitch packaging;

3. It has excellent chemical activity, solder ball elimination, and wettability;

4. The operation is simple. Equipment such as reflow ovens, electric hot plates, and stoves can be used;

5. It has excellent viscosity, outstanding stability, no delamination, and long stencil life.