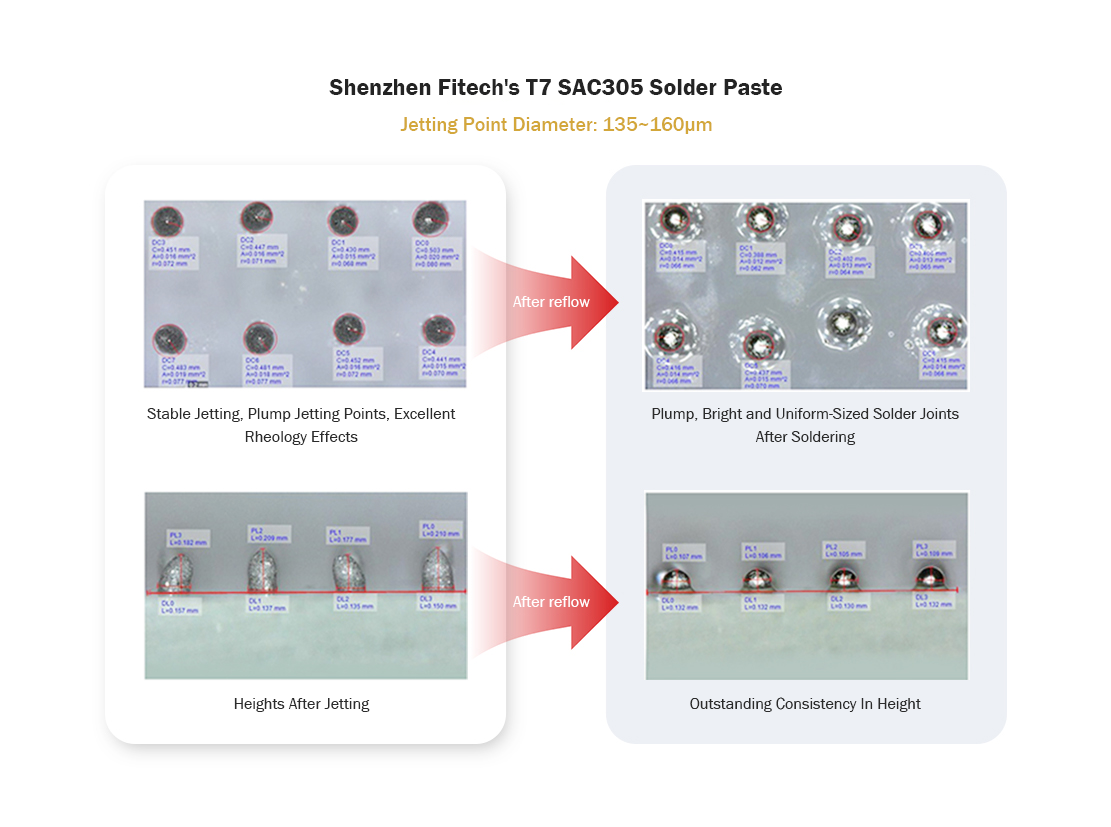

The technology of accurately distributing the solder paste on the solder pads by jetting (spraying) through the solder paste printer is called solder paste jetting technology. The solder paste used is called jetting solder paste. The jetting solder paste is applied to the small batch production of camera modules, FPCs, thermal sensors, MEMS, and other components that are incompatible with the printing or dispensing process.

The jetting solder paste should have superior properties such as thixotropy, rheology, wettability, etc.

Jetting solder paste is a high-end solder paste especially suitable for the spray printing process. Jetting is a solder paste deposit method without using a stencil, which provides a new process method for solder paste printing and dispensing. The jetting machine sprays the solder paste at a very high speed on the substrate, which is contactless similar to the inkjet printer. Solder paste jetting can meet the increasing requirements of substrate complexity and the highest quality requirements. Users can control the solder paste capacity required for each component's lead to ensure the best solder joint quality. Jetting is suitable for the solder paste deposit of complex substrates with uneven structure and TFT process and can realize solder paste patterns such as point, line, and plane.