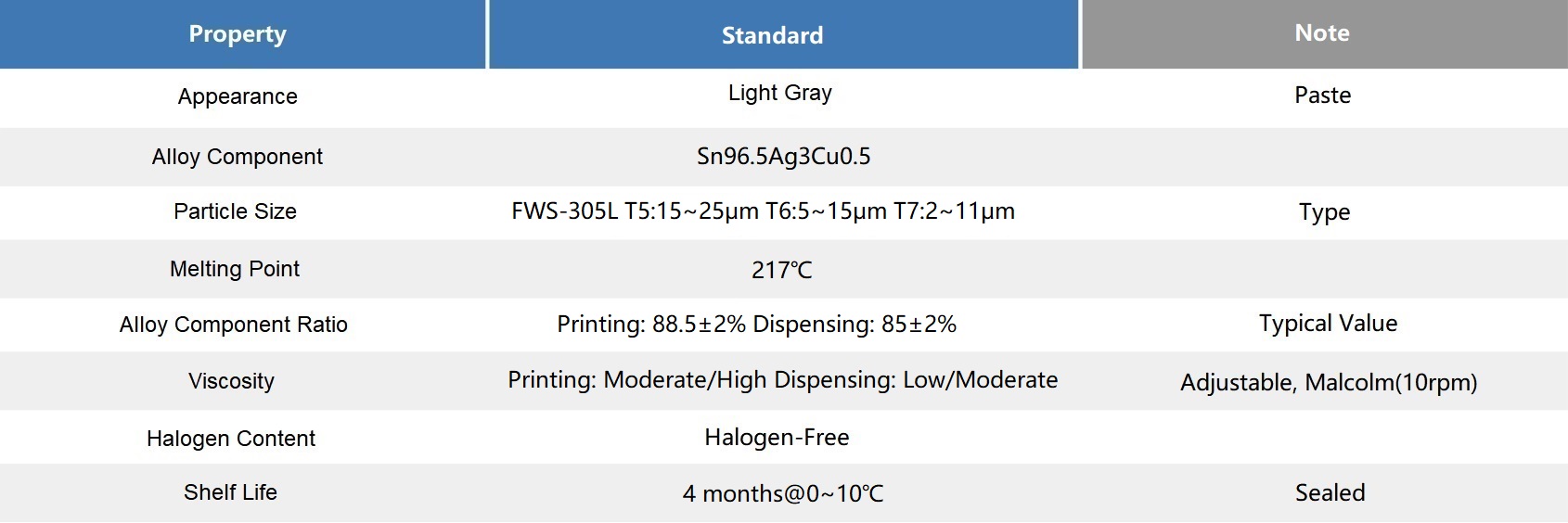

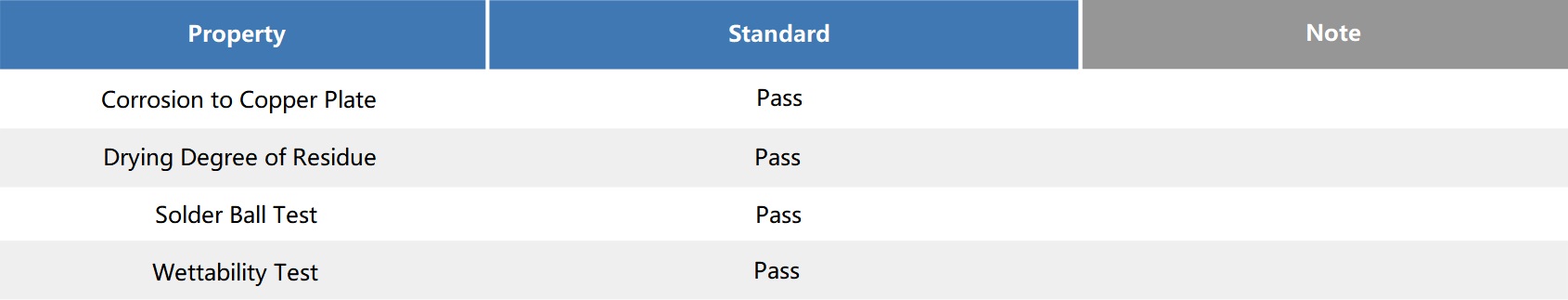

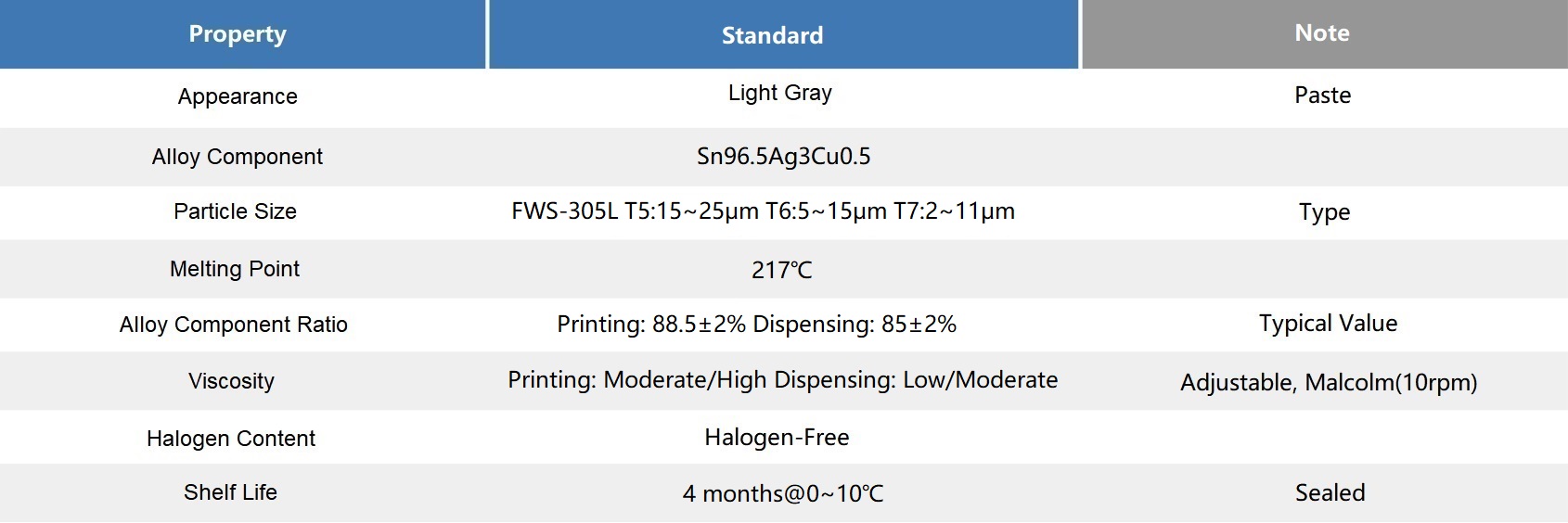

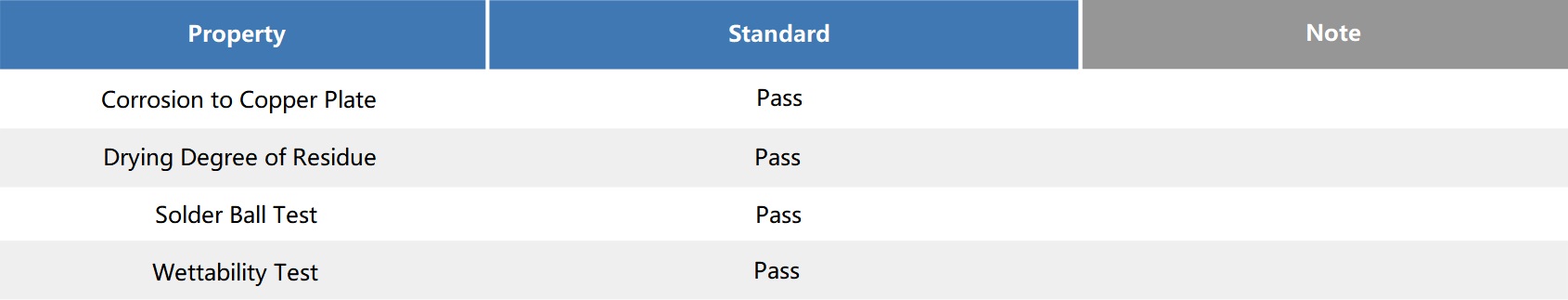

FWS-305L water-soluble laser solder paste is formulated with SAC305 solder powder and excellent halogen-free water-soluble flux. FWS-305L has superior adhesion performance before soldering, which can meet the laser soldering process requirement. In addition, the product has many advantages like excellent soldering effect, no spatter, and outstanding water solubility, which makes it suitable for high-reliability micro-bump ultra-fine-pitch packaging.

Warming Method: The sealed solder paste should rewarm to room temperature naturally; Rewarm no more than twice.

Warming Time: Rewarm 2 to 3 hours at room temperature. The actual time required to reach thermal equilibrium varies by vessel size.

Note: Do not open the bottle cap without sufficient rewarming or shorten the rewarming time by using heating equipment.

Operating Environment: The best operating temperature and humidity are 20-25°C and 40-60%RH, respectively. Reflow soldering in a nitrogen atmosphere is recommended.

Cleaning Instruction: There is a small amount of residue around the pad after reflow, which should be cleaned with deionized water as soon as possible. The temperature of deionized water is between 25°C and 60°C .