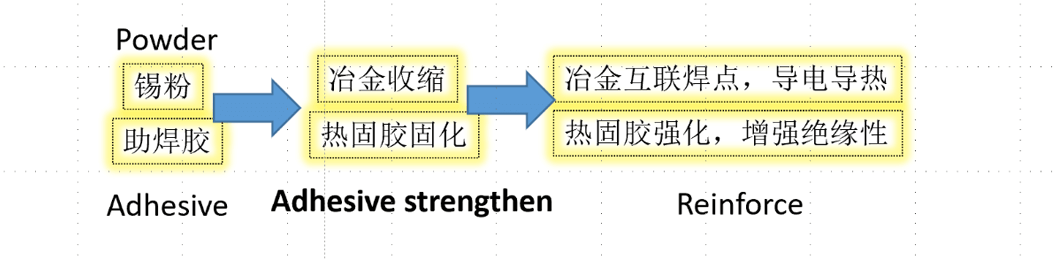

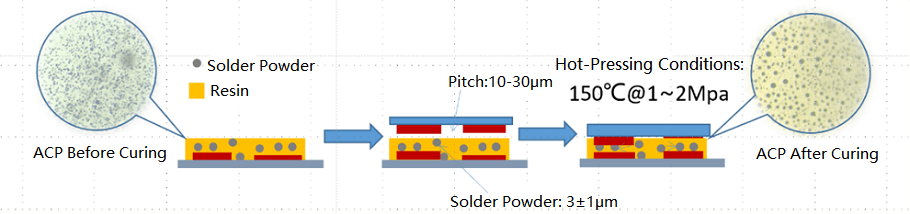

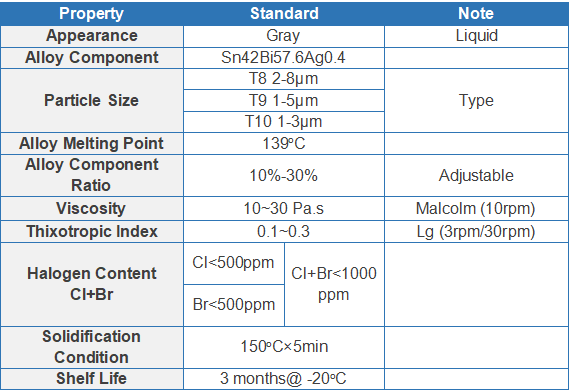

Low-temperature metallurgical-connection halogen-free anisotropic conductive paste is used to manufacture touch screens, smart cards, radio frequency identifications (RFID), flip chips, flexible printed circuits (FPC), and other products. It applies to the assembly and packaging of microelectronic circuits with ultra-fine pitch and is accelerating the miniaturization of microelectronic packaging. It is used in soldering on two fine-pitch conductive connection points in the manufacturing process of electronic components to avoid short circuits and improve the product's yields.

-

PRODUCTS

- ULTRA-FINE SOLDER PASTE

- ULTRA-FINE EPOXY SOLDER PASTE

- GOLD-TIN SOLDER PASTE

- SOLDER PASTE FOR MULTIPLE REFLOW SOLDERING

- LASER SOLDER PASTE

- WATER-SOLUBLE SOLDER PASTE

- JETTING SOLDER PASTE

- FLUX

- HIGH/LOW TEMPERATURE SOLDER PASTE

- LEAD-FREE SOLDER PASTE

- ULTRA-FINE SOLDER POWDER

- LOW ALPHA SOLDER PASTE/SOLDER POWDER

- SMT SOLDER POWDER

- CUSTOMIZED PACKAGING SOLDER

- APPLICATIONS

- MARKET AREA

- TECHNICAL SUPPORT

- NEWS

- ABOUT US