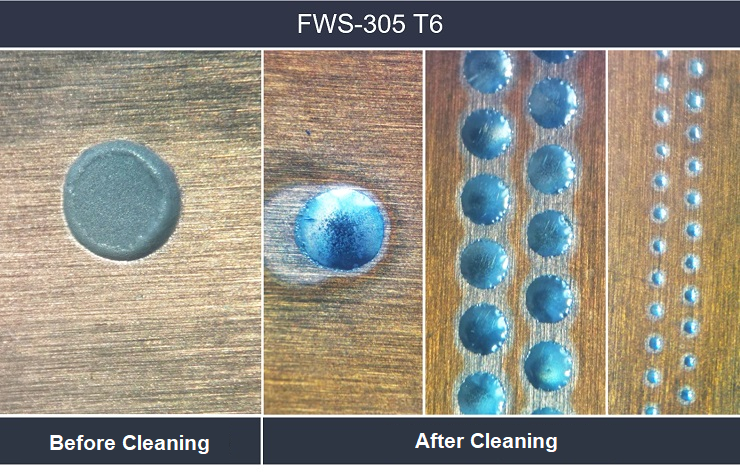

1. Product: Lead-free solder paste;

2. Flux: No-clean rosin resin, water-washable rosin resin, and water-based washing rosin resin;

3. Applications: Mini LED medium-temperature packaging and secondary reflow soldering with alloy melting temperatures of 217℃ to 219℃;

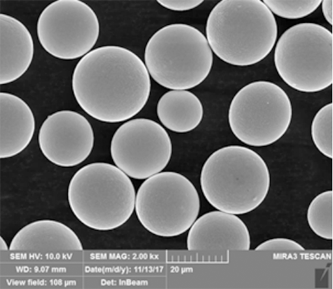

4. Type: T6(particle size: 5-15μm)-T9 (particle size: 1-5μm);

5. Advantages: Wide application, mature technology, various products available, high reliability, and small particle sizes;

6. Disadvantages: Higher reflow temperature than that of Sn63Pb37 eutectic solder;

7. Processes: Printing, dispensing, needle transfer, and jet printing;

8. Reflow under nitrogen protection (reflow oxygen content ≤100ppm).