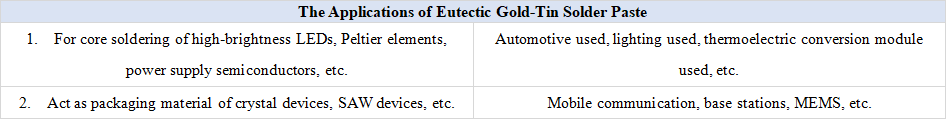

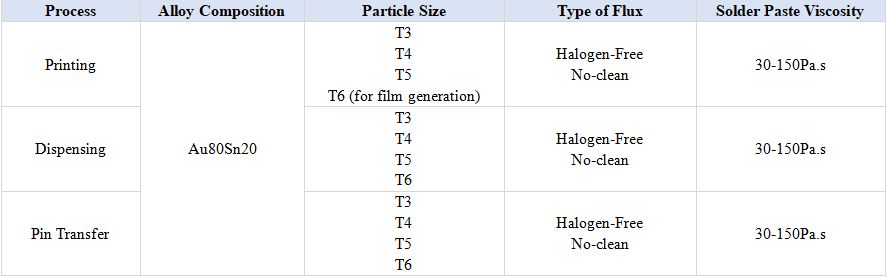

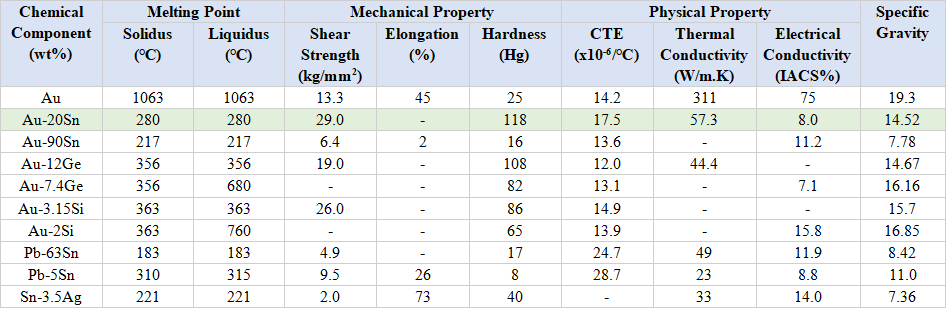

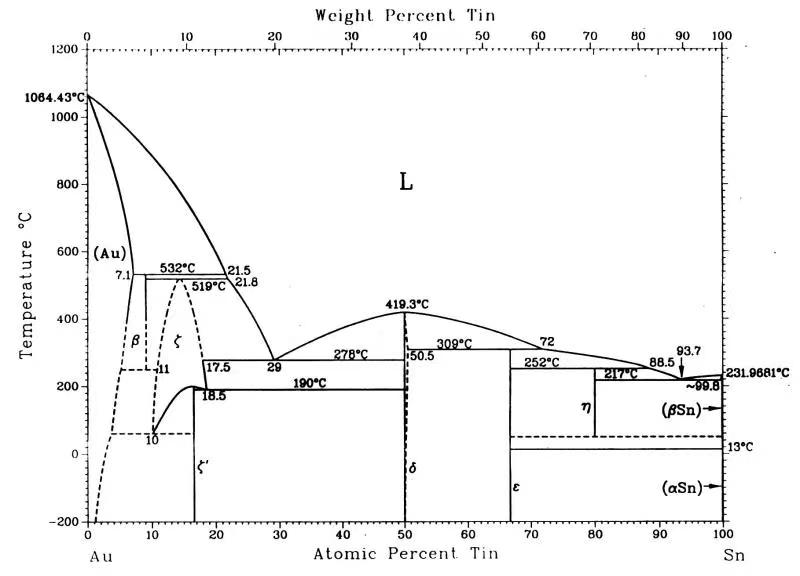

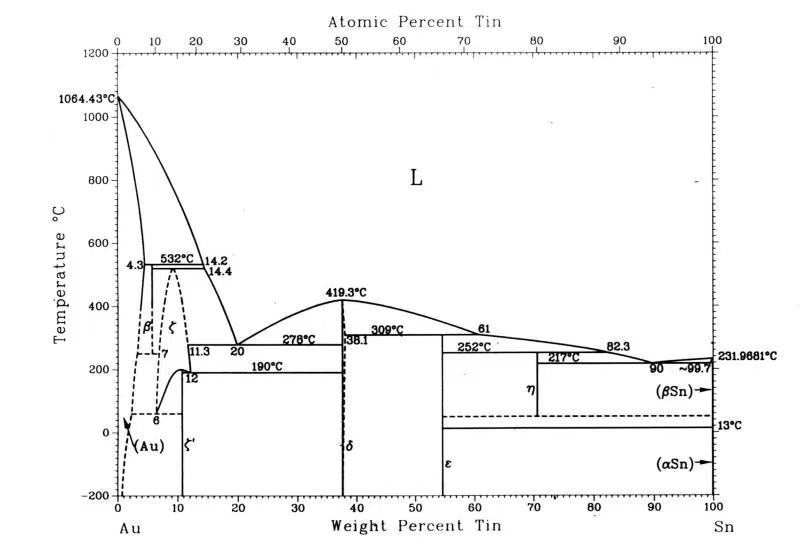

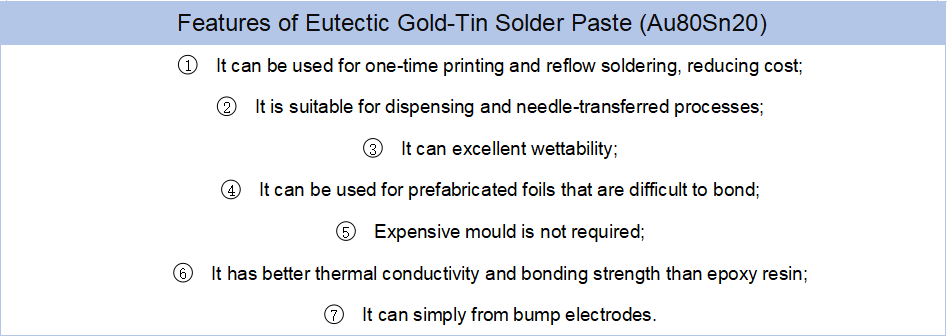

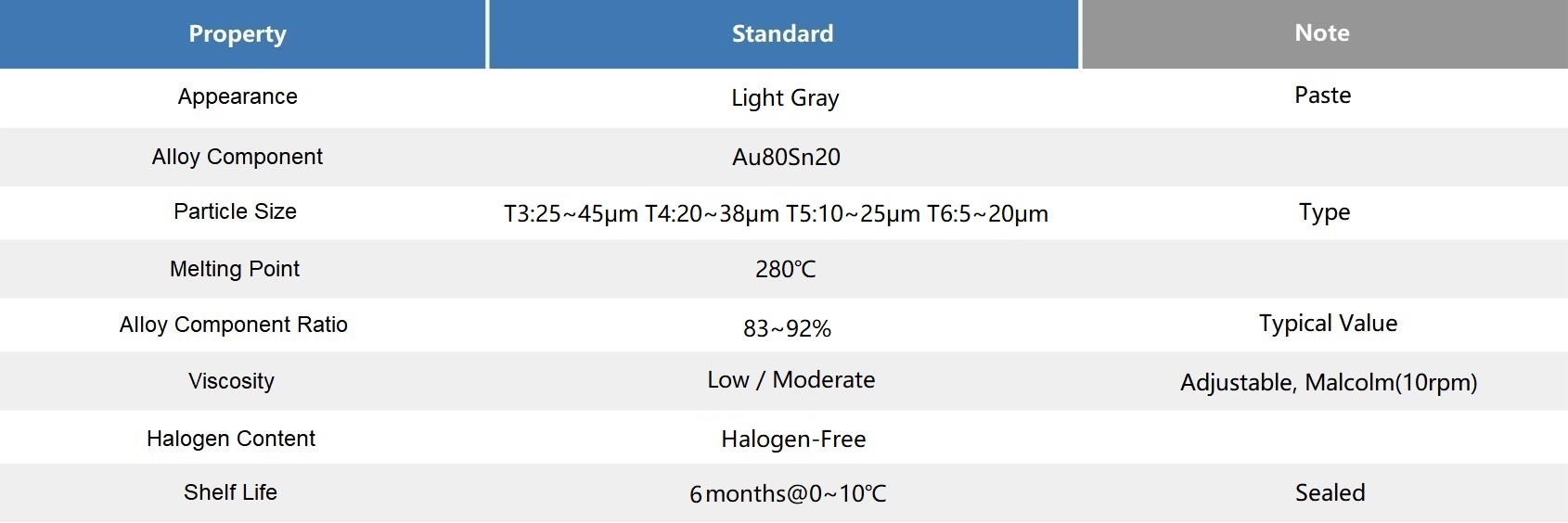

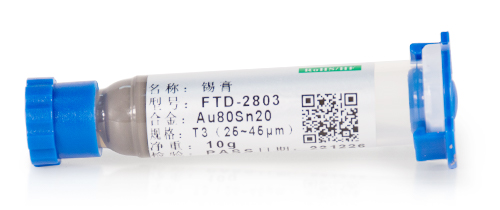

The alloy of Fitech's FH-280 series eutectic gold-tin solder paste consists of 80wt% of gold and 20wt% of tin (Au80Sn20). Under the impact of excellent characteristics of the FH-280 product and Fitech's advanced powder manufacturing technology, FH-280 has several advantages such as high tensile strength, outstanding corrosion resistance, excellent thermal creep performance, and extraordinary compatibility with other precious metals. It also has excellent electrical conductivity and thermal conductivity. FH280 series solder paste has a melting point of 280℃ and particle sizes covering T3 to T6. It supports the printing and dispensing process.