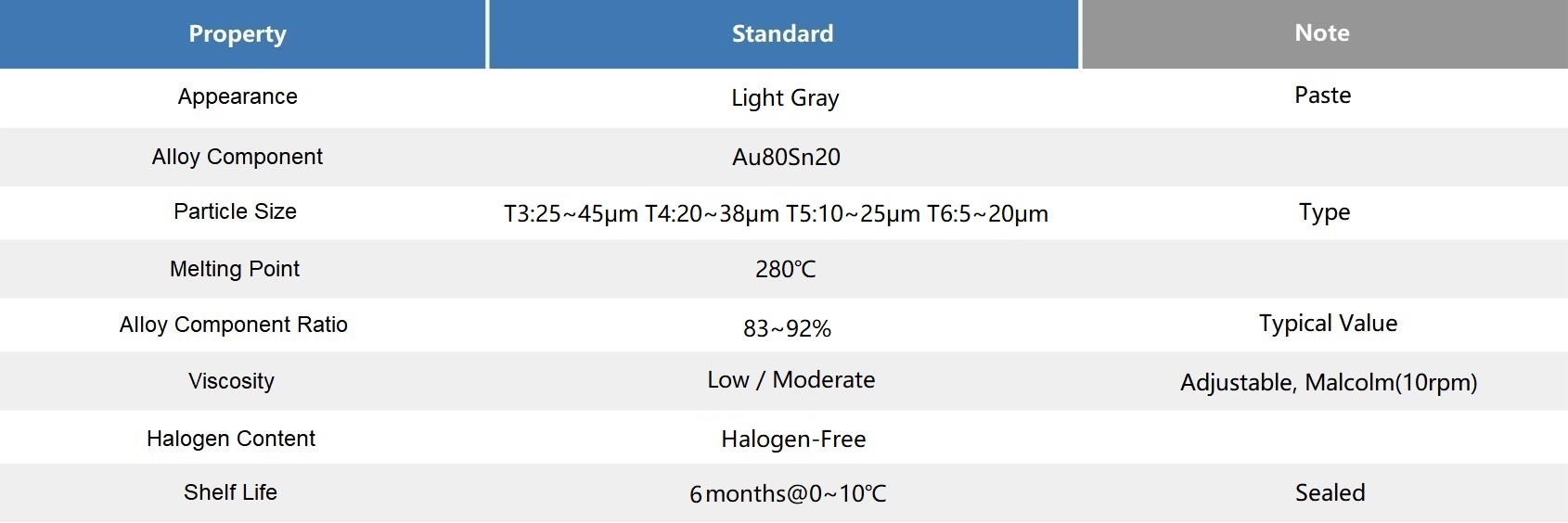

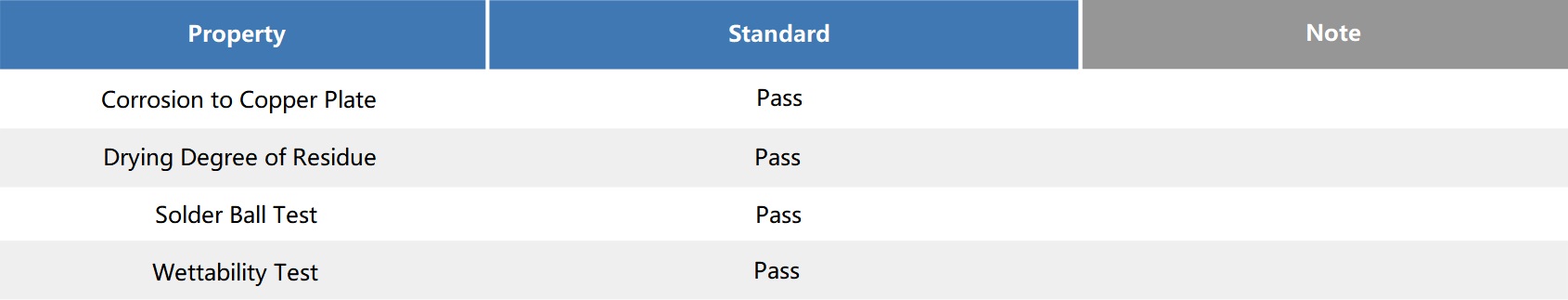

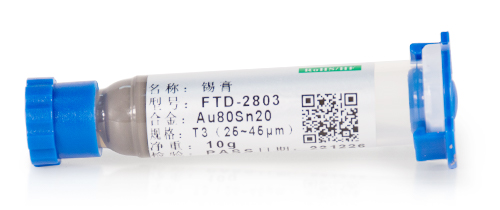

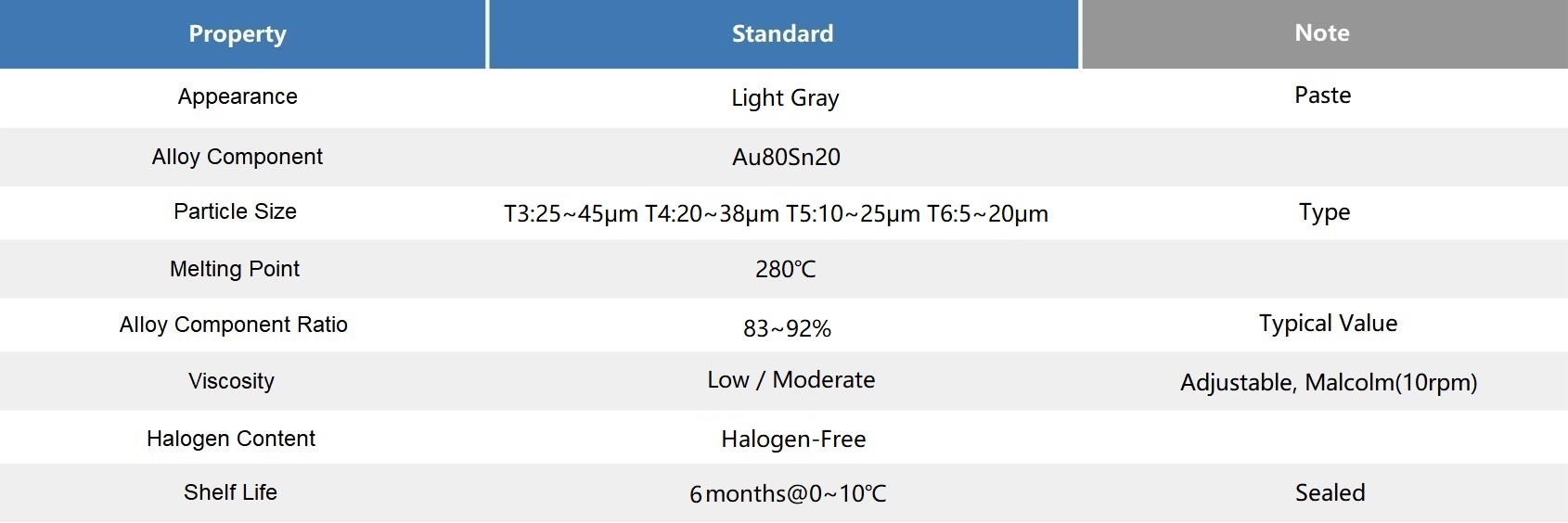

An80Sn20 solder powder with excellent sphericity, uniform particle size, and low oxygen content is combined with halogen-free flux to produce FH-280 series solder paste. FH-280 has a superior adhesion effect before soldering. Solvent volatilizes very slightly during soldering. In addition, the solder paste has outstanding wettability, anti-slump, and residue reduction properties. There is no solder ball formation during soldering. Moreover, FH-280 has high tensile strength, excellent corrosion resistance, high melting point, and extraordinary thermal creep performance. FH-280 is compatible with other precious metals and has excellent electrical and thermal conductivity. The product is suitable for the high-reliability packaging of semiconductors and microelectronic devices. It is applied to the high thermal conductivity packaging of high-power devices.

Warming Method: The sealed solder paste should rewarm to room temperature naturally; Rewarm no more than twice.

Warming Time: Rewarm 2 to 3 hours at room temperature. The actual time required to reach thermal equilibrium varies by vessel size.

Note: Do not open the bottle cap without sufficient rewarming or shorten the rewarming time by using heating equipment.

Operating Environment: The best operating temperature and humidity are 20-25°C and 40-60%RH, respectively. Reflow soldering in a nitrogen atmosphere is recommended.