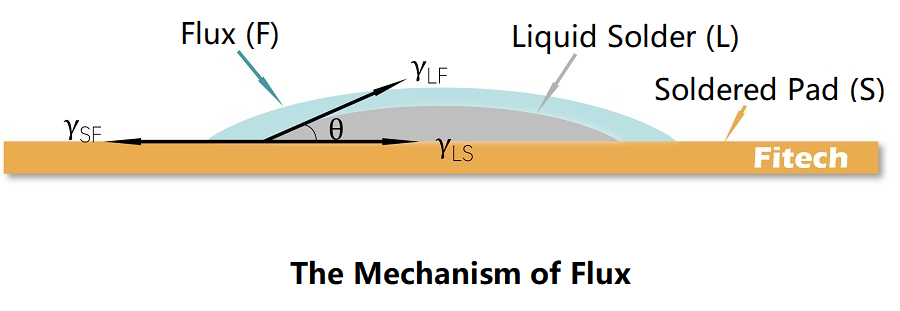

Water-soluble flux is a kind of flux widely used in the electronic soldering process, it can improve the wetting performance of the solder, prevent oxidation, and after soldering with water to clean the residue.

The biggest feature of water-soluble flux is that the flux component is highly soluble and active in water, with good fluxing performance, and the post-soldering residue is easily soluble in water, so water can be directly used as the cleaning solvent. No consumption of ODS and VOC, reducing environmental pollution and safety risks.