Low-temperature solder paste has an alloy melting point lower than 180oC, and the peak reflow temperature should not be greater than 200oC. It is used in the second reflow of the secondary reflow process, and it can be used for the packaging of non-heat-resistant and heat-dissipating components. The low-temperature solder powder is synthesized based on bismuth elements by adding other metal powders.

FTP-574

FTD-170

FTD-574

FTP-170

FACA-138D

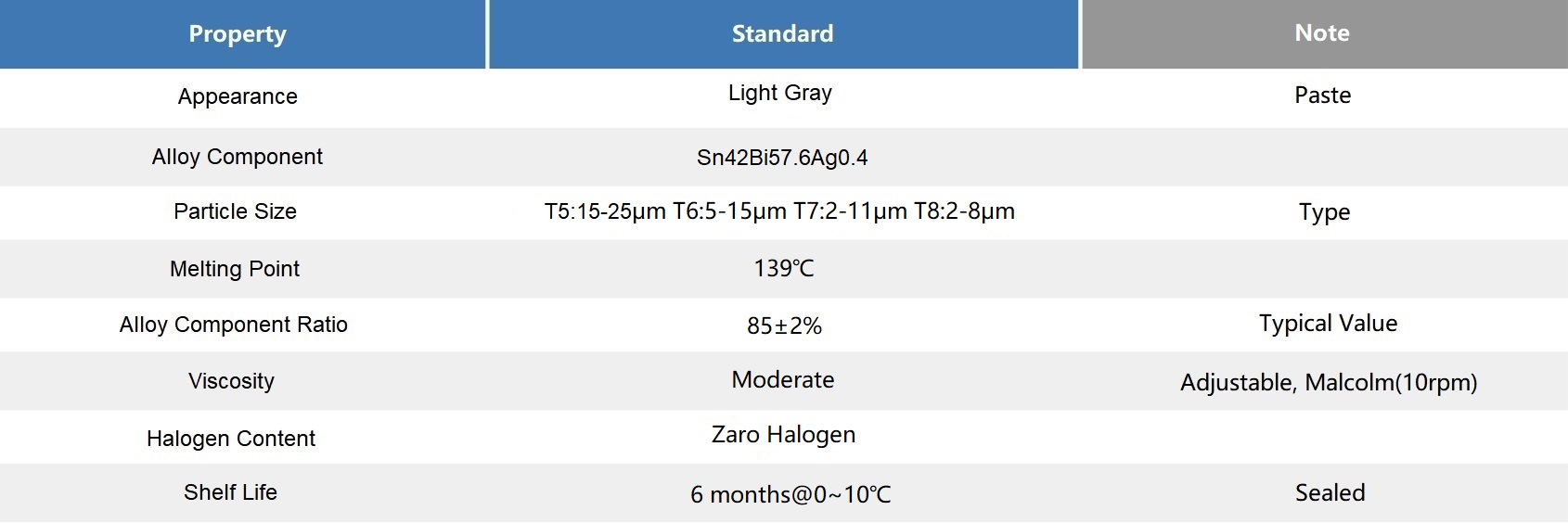

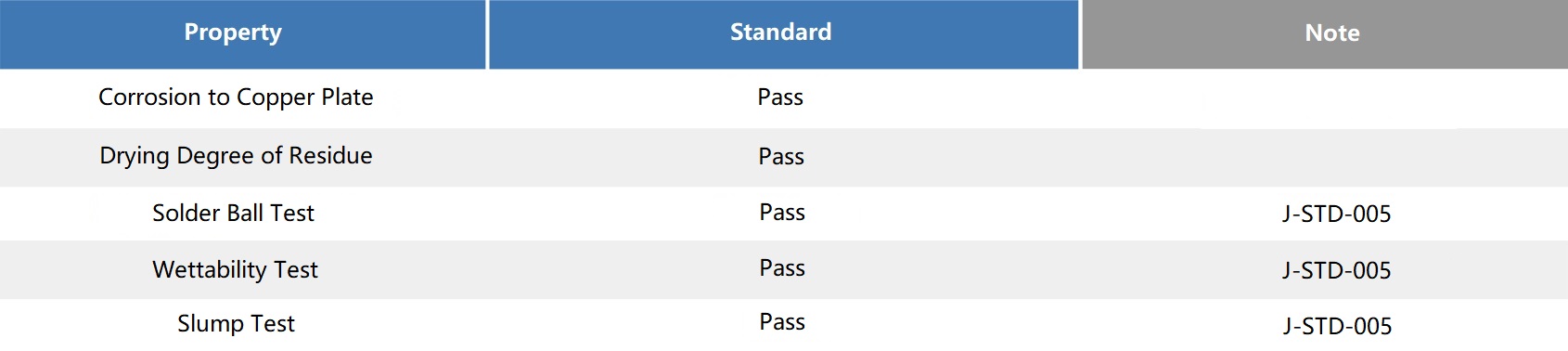

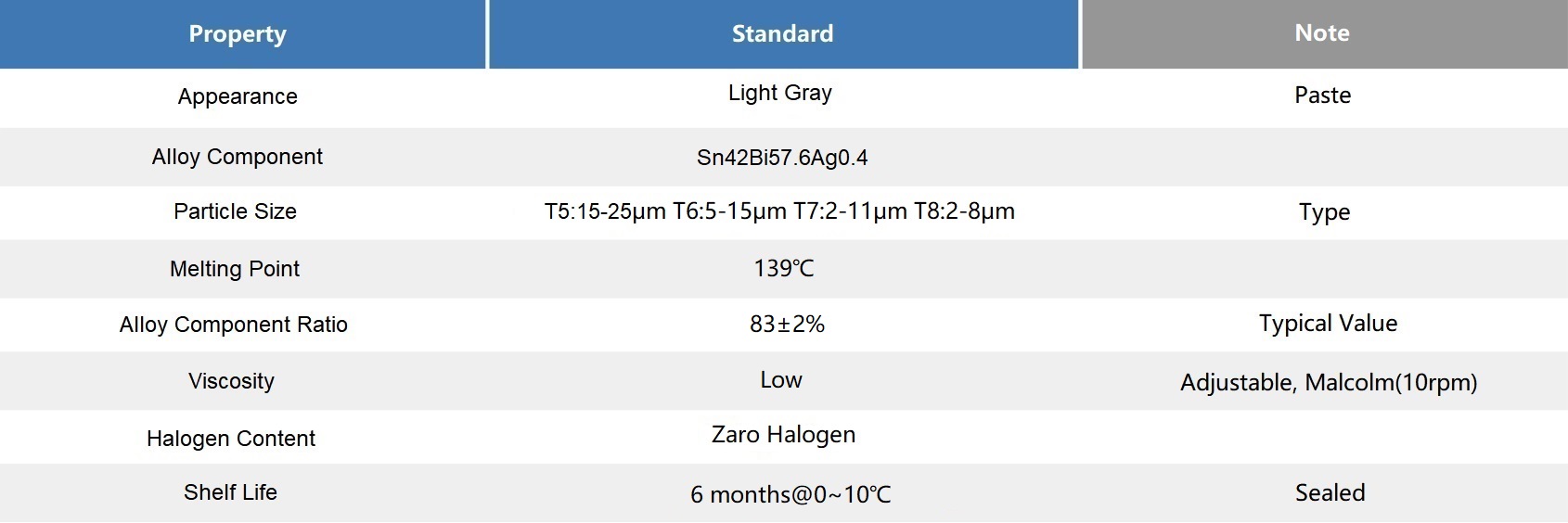

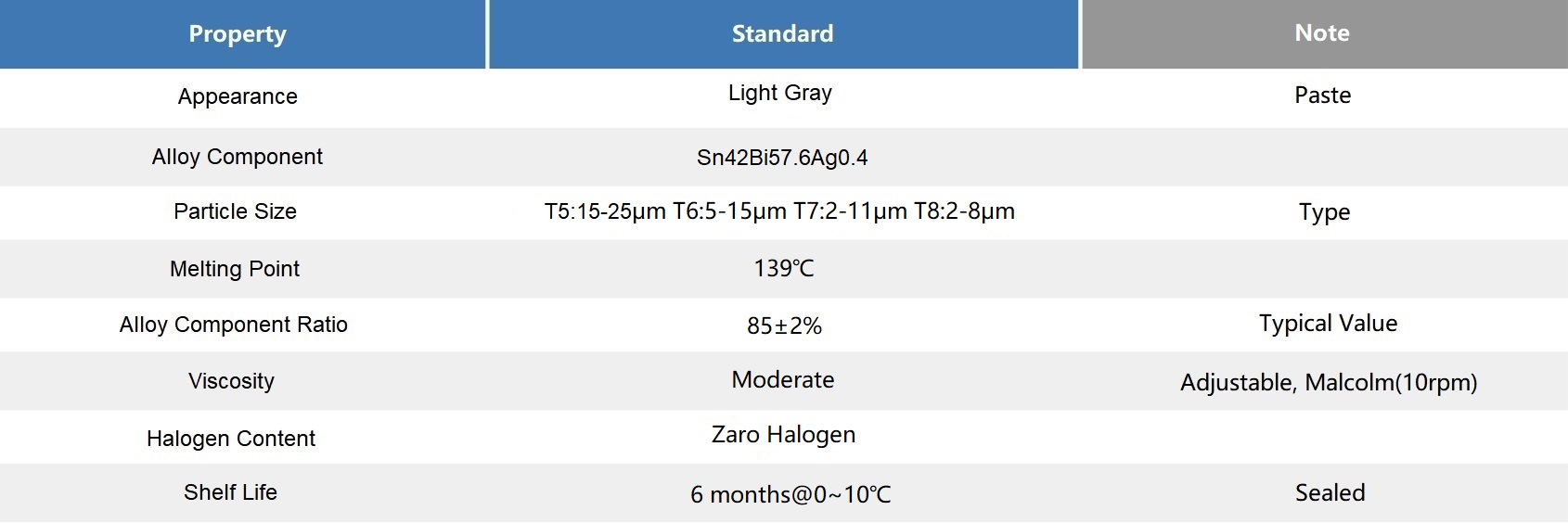

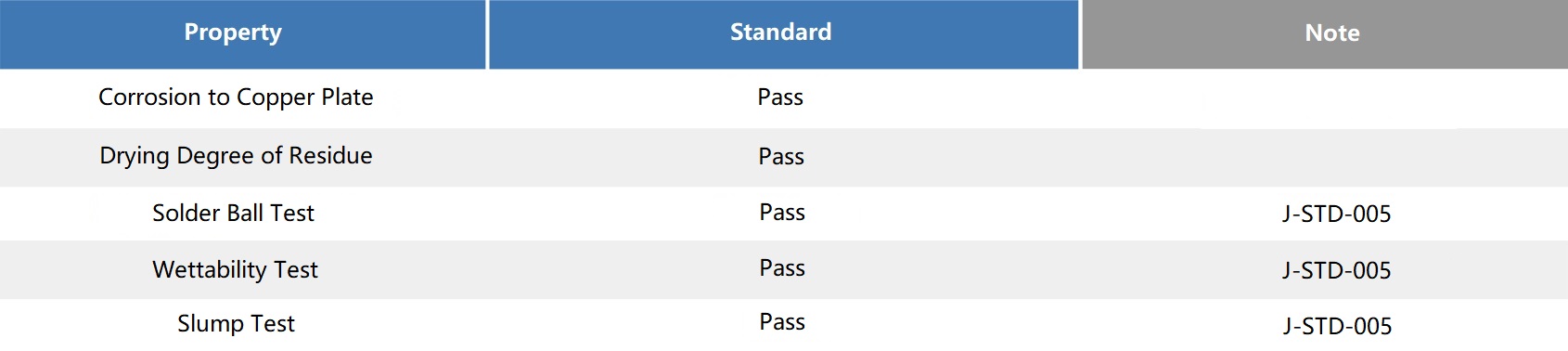

Fitech's tin-bismuth-silver alloy solder powder with excellent sphericity, uniform particle size, and low oxygen content is mixed with excellent zero-halogen flux to prepare FTP-574 series low-temperature solder paste. Solvent volatilizes very slightly during soldering. There is no solder ball formation and only a small amount of residue forms after soldering. Moreover, the product has outstanding wettability, and the solder joints generated are plump and bright. It is effective for low-temperature component mounting.

1. Warming Instruction: Solder paste needs to be refrigerated, and the preferred temperature is 0-10°C. When the solder paste is taken out from the cold box, its temperature is much lower than the room temperature. If the bottle cap is opened without rewarming, the water vapor in the air will easily condense and adhere to the solder paste. The high temperature exceeding 150°C during soldering increases vaporizatipn of water, which may cause the phenomenon of "exploding solder" to produce solder balls and even damage the components.

2. Warming Method: The sealed solder paste should rewarm to room temperature naturally; Rewarm no more than twice.

3. Warming Time: Return to warm for 2 to 3 hours at room temperature. The actual time required to reach thermal equilibrium varies by vessel size.

4. Note: Do not open the bottle cap without sufficient rewarming or shorten the rewarming by using heat equipment.

5. Operating Environment:The best operating temperature and humidity are 20-25°C and 40-50%RH, respectively. Reflow soldering in a nitrogen atmosphere is recommended.

6. Operating Time

① Continuous printing time: When adding solder paste continuously: 8 hours; In case of discontinuous addition of solder paste: 4 hours; ② Please add solder paste before the solder paste on the board is almost one third (rolling diameter: 10mm or less); ③ Please keep the solder paste on the plate within 3 hours; ④ If printing is interrupted for more than 30 minutes, please clean the stencil. ⑤ Dwell time after printing: After the solder paste is printed, the components should be mounted as soon as possible and the soldering should be completed when passing the oven to avoid drying out the surface of the solder paste due to long storage, which will affect the component mounting and soldering effects. Generally, the recommended dwell time of solder paste is no more than 4 hours, while the low temperature bismuth-containing solder paste does not exceed 2 hours. If the printing is interrupted for more than 30 minutes or is temporarily interrupted, the printing template needs to be cleaned. It can continue to work after 1-2 trial printing. The solder paste attached to narrow space of the opening (≤0.4mm) and the opening of the stencil will gradually dry, which will degenerate the adhesive ability.

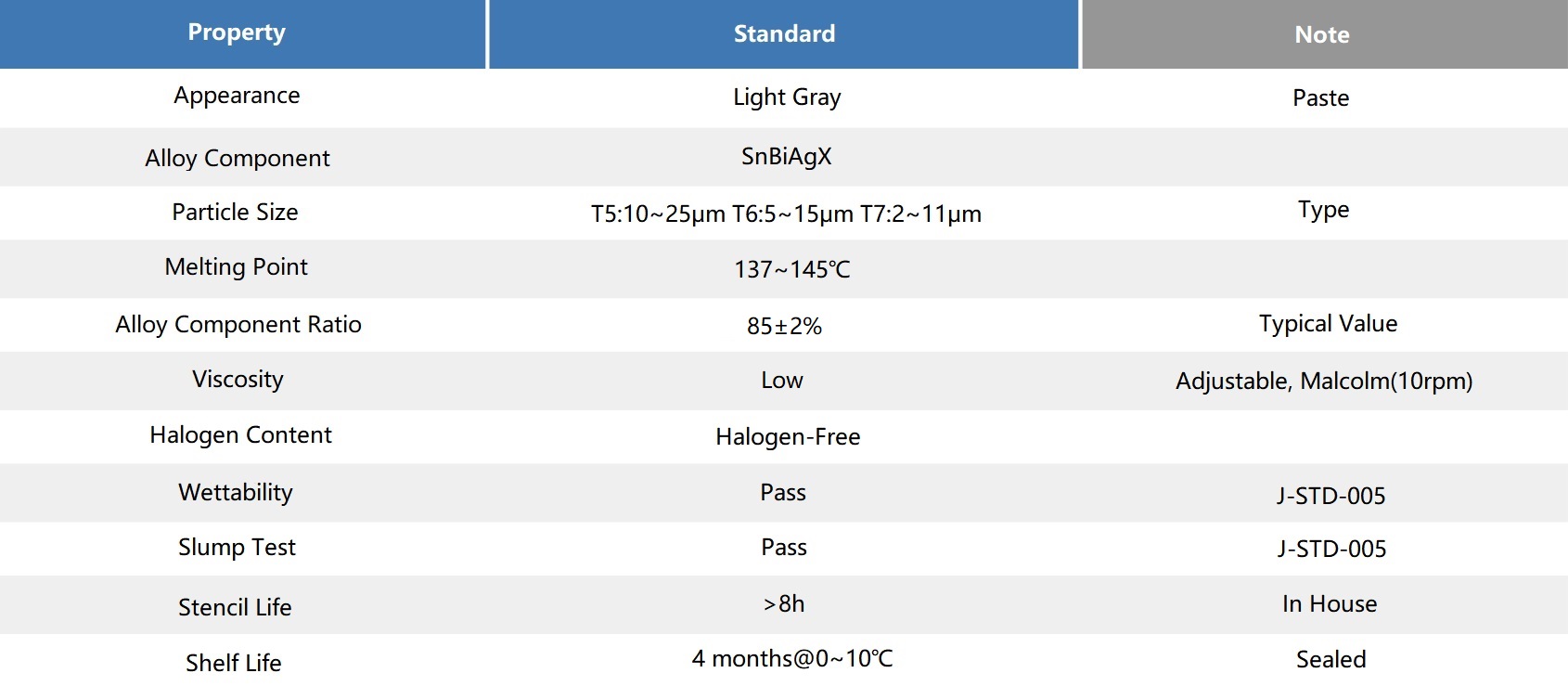

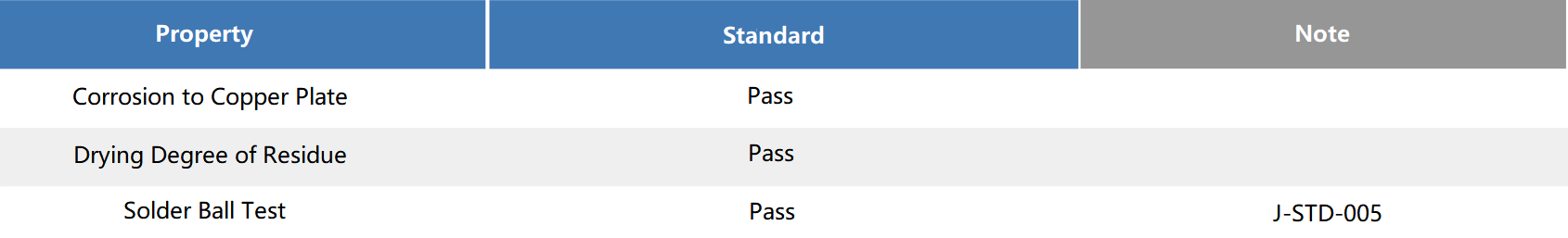

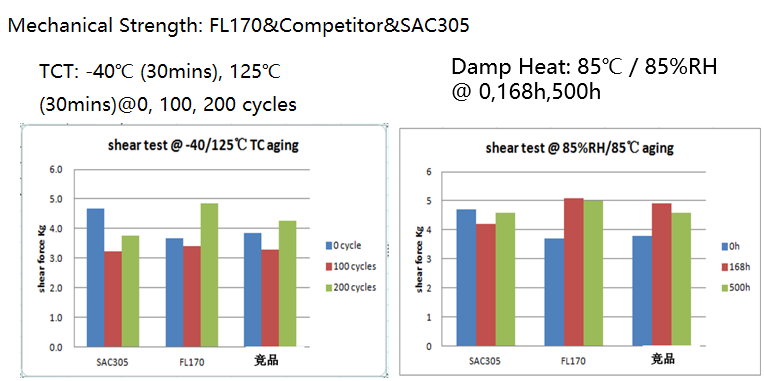

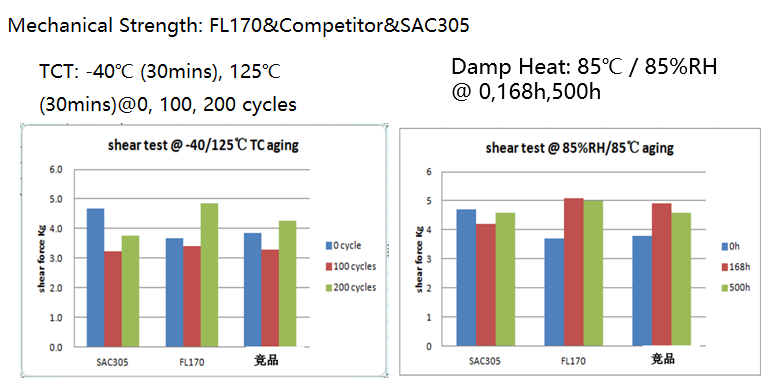

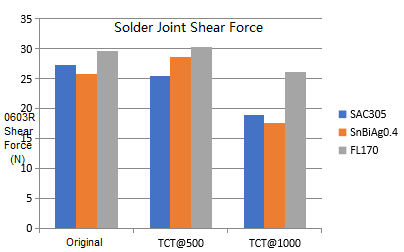

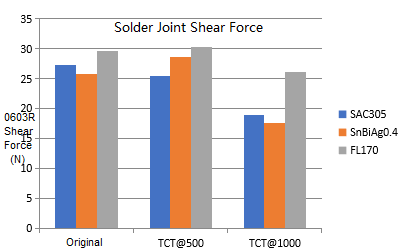

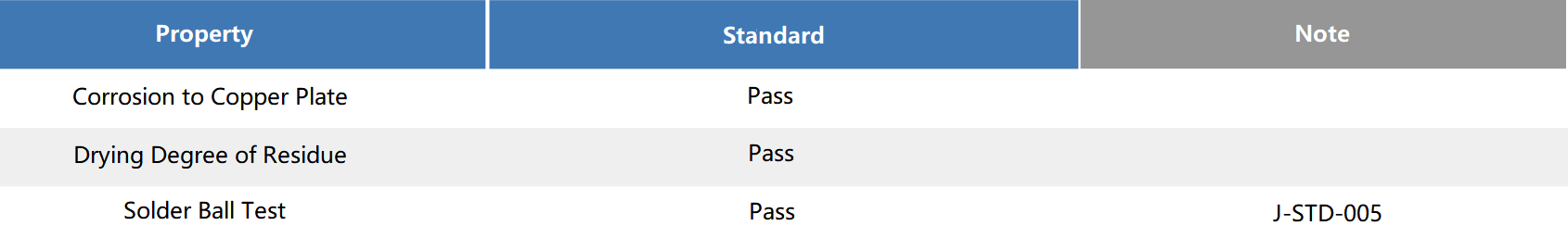

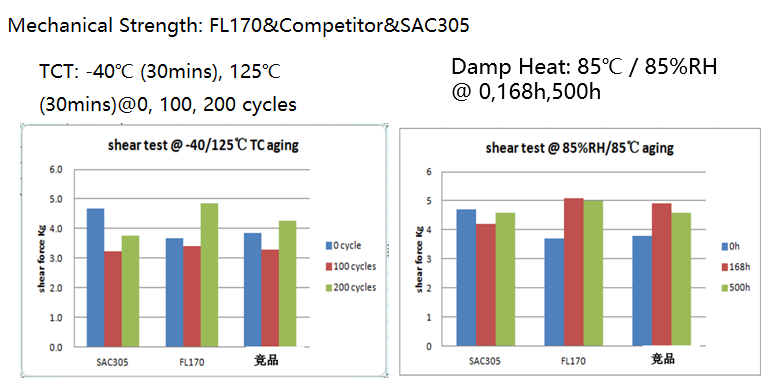

Low-temperature FL170 alloy solder powder with good sphericity, uniform particle size, low oxygen content, and high strength are combined with zero-halogen flux to produce FTD-170 series low-temperature solder paste. Only a small amount of solvent volatilizes during the soldering process. There is no solder ball formation after soldering. The solder paste has excellent performance of residue minimization and wettability. The solder joints generated are strong, plump, and bright. FTD-170 is ideal for low-temperature soldering, especially for low-temperature component mounting.

1. Warming Instruction: Solder paste needs to be refrigerated, and the preferred temperature is 0-10°C. When taking out the solder paste from the cold box, its temperature is much lower than the room temperature. If the bottle cap is opened without rewarming, the water vapor in the air will easily condense and adhere to the solder paste.The high temperature exceeding 150°C during soldering increases the vaporization of water, which may cause the phenomenon of "exploding solder" to produce solder balls and even damage the components.

2. Warming Method: The sealed solder paste should rewarm to room temperature naturally; Rewarm no more than twice.

3. Warming Time: Return to warm for 2 to 3 hours at room temperature. The actual time required to reach thermal equilibrium varies by vessel size.

4. Note: Do not open the bottle cap without sufficient rewarming or shorten the rewarming time by using heat sources.

5. Operating Environment: The best operating temperature and humidity are 20-25°C and 40-60%RH, respectively. Reflow soldering in a nitrogen atmosphere is recommended.

6. Operating Time

① Continuous printing time: When adding solder paste continuously: 8 hours; In case of discontinuous addition of solder paste: 4 hours; ② Please add solder paste before the solder paste on the board is almost one third (rolling diameter: 10mm or less); ③ Please keep the solder paste on the plate within 3 hours; ④ If printing is interrupted for more than 30 minutes, please clean the stencil. ⑤ Dwell time after printing: After the solder paste is printed, the components should be mounted as soon as possible and the soldering should be completed when passing the oven to avoid drying out the surface of the solder paste due to long storage, which will affect the component mounting and soldering effects. Generally, the recommended dwell time of solder paste is no more than 4 hours, while the low-temperature bismuth-containing solder paste does not exceed 2 hours. If the printing is interrupted for more than 30 minutes or is temporarily interrupted, the printing template needs to be cleaned. It can continue to work after 1-2 trial printing. The solder paste attached to the narrow space of the opening (≤0.4mm) and the opening of the stencil will gradually dry, which will degenerate the adhesive ability.

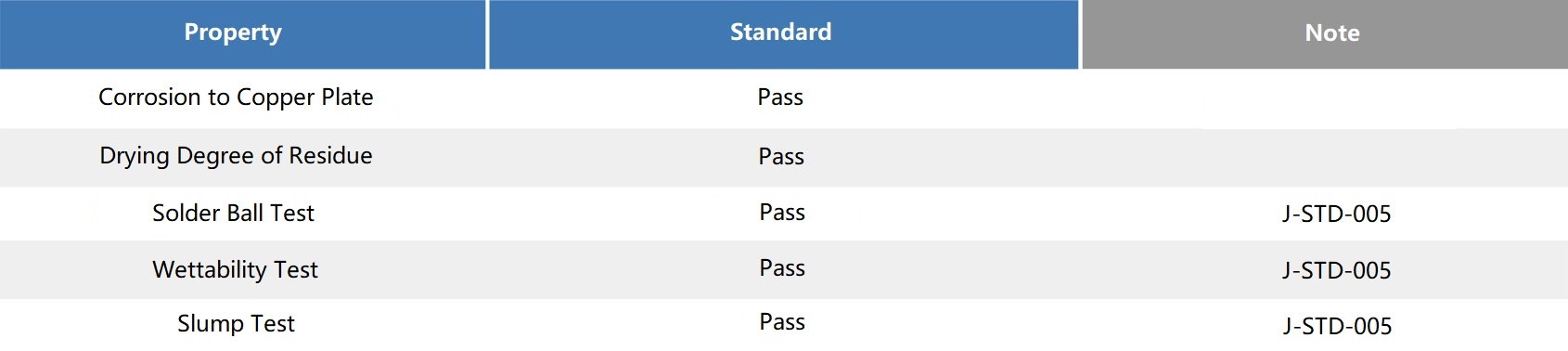

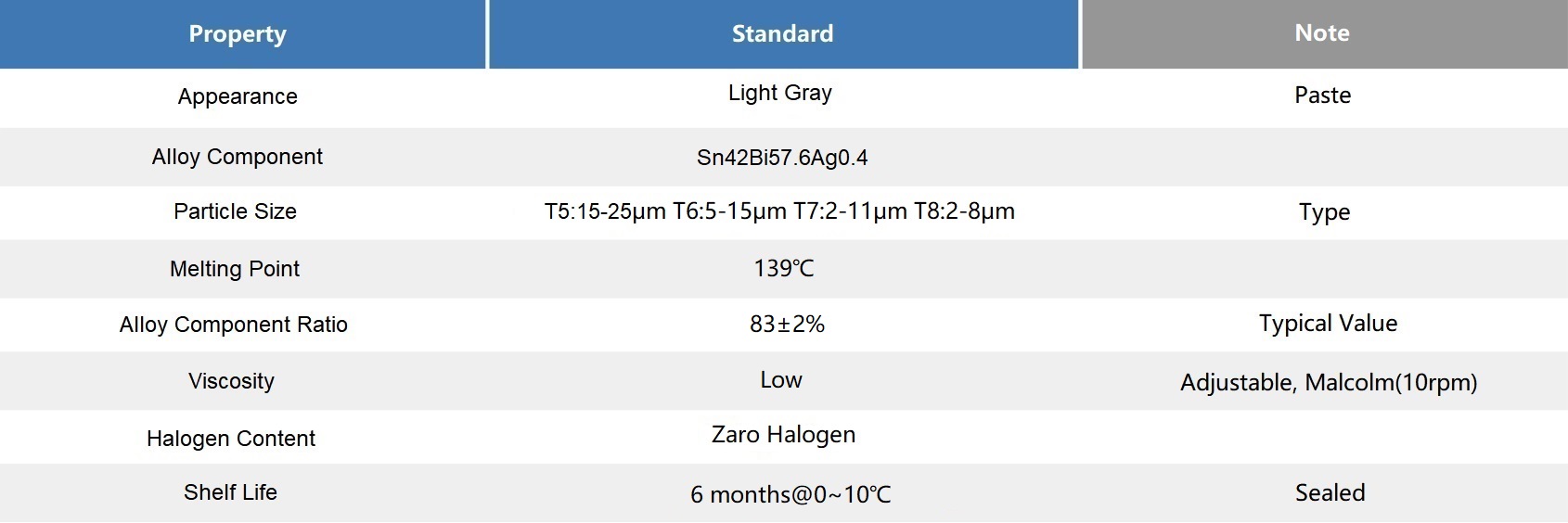

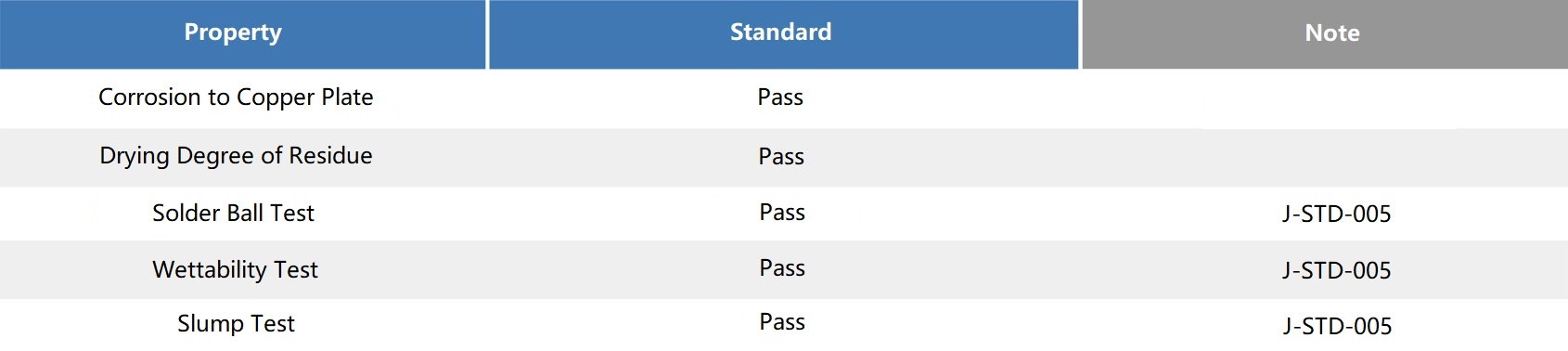

Fitech’s tin-bismuth-silver solder powder with excellent sphericity, uniform particle size, and low oxygen content is mixed with excellent zero-halogen flux to prepare FTD-574 series low-temperature solder paste. Solvent volatilizes very slightly during soldering. There is no solder ball formation during soldering, and only a small amount of residue is produced after soldering. Moreover, FTD-574 has outstanding wettability. The solder joints generated are plump and bright. The product is effective for low-temperature component mounting.

1. Warming Instruction: Solder paste usually needs to be refrigerated, and the preferred temperature is 0-10°C. When taking out the solder paste from the cold box, its temperature is much lower than the room temperature. If the bottle cap is opened without rewarming, the water vapor in the air will easily condense and adhere to the solder paste. The high temperature exceeding 150°C during soldering increases the vaporization of water, which may cause the phenomenon of "exploding solder" to produce solder balls and even damage the components.

The temperature exceeds 150℃), the water vaporizes rapidly due to the strong heat, which is easy to cause the phenomenon of "exploding tin" to produce tin beads and even damage the components.

温度超过150℃),水受强热迅速汽化,易造成“爆锡”现象产生锡珠,甚至损坏元器件。

The temperature exceeds 150℃), the water vaporizes rapidly due to the strong heat, which is easy to cause the phenomenon of "exploding tin", resulting in tin beads and even damage to the components.

温度超过150℃),水受强热迅速汽化,易造成“爆锡”现象,产生锡珠,甚至损坏元器件。

无法加载全部结果

重试

正在重试…

正在重试…

无法加载全部结果

重试

正在重试…

正在重试…

2. Warming Method: The sealed solder paste should rewarm to room temperature naturally; Rewarm no more than twice.

2. Warming method: Under the premise of not opening the lid, return to temperature naturally at room temperature; the number of times of returning to temperature is no more than twice;

2、升温方法:在不开盖的前提下,在室温下自然回温;回温次数不超过两次;

2. Warming method: Under the premise of not opening the lid, return to temperature naturally at room temperature; the number of times of returning to temperature is no more than two times;

2、升温方法:在不开盖的前提下,在室温下自然回温;回温次数不超过2次;

无法加载全部结果

重试

正在重试…

正在重试…

无法加载全部结果

重试

正在重试…

正在重试…

3. Warming Time: Return to warm for 2 to 3 hours at room temperature. The actual time required to reach thermal equilibrium varies by vessel size.

The actual time required to reach thermal equilibrium varies by vessel size.

达到热平衡所需的实际时间因容器尺寸而异。

The actual time required to reach thermal equilibrium will vary depending on the size of the vessel.

达到热平衡所需的实际时间将根据容器的大小而有所不同。

无法加载全部结果

重试

正在重试…

正在重试…

无法加载全部结果

重试

正在重试…

正在重试…

4. Note: Do not open the bottle cap without sufficient rewarming or shorten the rewarming time by using heating equipment.

Note: Do not open the bottle cap without sufficient "rewarming", and do not shorten the "rewarming" time by heating;

注意:没有充分“复温”就不要打开瓶盖,也不要通过加热来缩短“复温”时间;

Note: Do not open the bottle cap without sufficient "rewarming", and the "rewarming" time cannot be shortened by heating;

注意:没有充分“复温”就不要打开瓶盖,加热不能缩短“复温”时间;

无法加载全部结果

重试

正在重试…

正在重试…

无法加载全部结果

重试

正在重试…

正在重试…

The actual time required to reach thermal equilibrium varies by vessel size.

达到热平衡所需的实际时间因容器尺寸而异。

The actual time required to reach thermal equilibrium will vary depending on the size of the vessel.

达到热平衡所需的实际时间将根据容器的大小而有所不同。

无法加载全部结果

重试

正在重试…

正在重试…

无法加载全部结果

重试

正在重试…

正在重试…

4. Note: Do not open the bottle cap without sufficient "rewarming", and do not shorten the "rewarming" time by heating;

...

4. Note: Do not open the bottle cap without sufficient "rewarming", and the "rewarming" time cannot be shortened by heating;

...

无法加载全部结果

重试

正在重试…

正在重试…

无法加载全部结果

重试

正在重试…

正在重试…

5. Operating Environment:The best operating temperature and humidity are 20-25°C and 40-50%RH, respectively. Reflow soldering in a nitrogen atmosphere is recommended.

6. Operation Time

① Continuous printing time: When adding solder paste continuously: 8 hours. In case of discontinuous addition of solder paste: 4 hours; ② Please add solder paste before the solder paste on the board is almost one third (rolling diameter: 10mm or less); ③ Please keep the solder paste on the plate within 3 hours; ④ If printing is interrupted for more than 30 minutes, please clean the stencil; ⑤ Dwell time after printing: After the solder paste is printed, the components should be mounted as soon as possible and the soldering should be completed when passing the oven to avoid drying out the surface of the solder paste due to long storage, which will affect the component mounting and soldering effects. Generally, the recommended dwell time of solder paste is no more than 4 hours, while the low temperature bismuth-containing solder paste does not exceed 2 hours. If the printing is interrupted for more than 30 minutes or is temporarily interrupted, the printing template needs to be cleaned. It can continue to work after 1-2 trial printing. The solder paste attached to narrow space of the opening (≤0.4mm) and the opening of the stencil will gradually dry, which will degenerate the adhesive ability.

Low-temperature FL170 alloy solder powder with excellent sphericity, uniform particle size, low oxygen content, and high strength are combined with zero-halogen flux to produce FTP-170 series low-temperature solder paste. Only a small amount of solvent volatilizes during the soldering process. There is no solder ball formation after soldering. In addition, FTP-170 has an excellent performance in residue minimization and wettability. The solder joints generated are strong, plump, and bright. The product is ideal for low-temperature soldering, especially for low-temperature component mounting.

1. Warming Instruction: Solder paste needs to be refrigerated, and the preferred temperature is 0-10°C. When taking out the solder paste from the cold box, its temperature is much lower than the room temperature. If the bottle cap is opened without rewarming, the water vapor in the air will easily condense and adhere to the solder paste.The high temperature exceeding 150°C during soldering increases the vaporization of water, which may cause the phenomenon of "exploding solder" to produce solder balls and even damage the components.

2. Warming Method: The sealed solder paste should rewarm to room temperature naturally; Rewarm no more than twice.

3. Warming Time: Return to warm for 2 to 3 hours at room temperature. The actual time required to reach thermal equilibrium varies by vessel size.

4. Note: Do not open the bottle cap without sufficient rewarming or shorten the rewarming time by using heating equipment.

5. Operating Environment:The best operating temperature and humidity are 20-25°C and 40-60%RH, respectively. Reflow soldering in a nitrogen atmosphere is recommended.

6. Operating Time

① Continuous printing time: When adding solder paste continuously: 8 hours; In case of discontinuous addition of solder paste: 4 hours; ② Please add solder paste before the solder paste on the board is almost one third (rolling diameter: 10mm or less); ③ Please keep the solder paste on the plate within 3 hours; ④ If printing is interrupted for more than 30 minutes, please clean the stencil. ⑤ Dwell time after printing: After the solder paste is printed, the components should be mounted as soon as possible and the soldering should be completed when passing the oven to avoid drying out the surface of the solder paste due to long storage, which will affect the component mounting and soldering effects. Generally, the recommended dwell time of solder paste is no more than 4 hours, while the low temperature bismuth-containing solder paste does not exceed 2 hours. If the printing is interrupted for more than 30 minutes or is temporarily interrupted, the printing template needs to be cleaned. It can continue to work after 1-2 trial printing. The solder paste attached to narrow space of the opening (≤0.4mm) and the opening of the stencil will gradually dry, which will degenerate the adhesive ability.

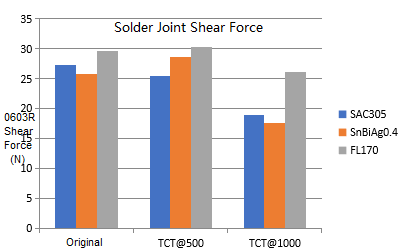

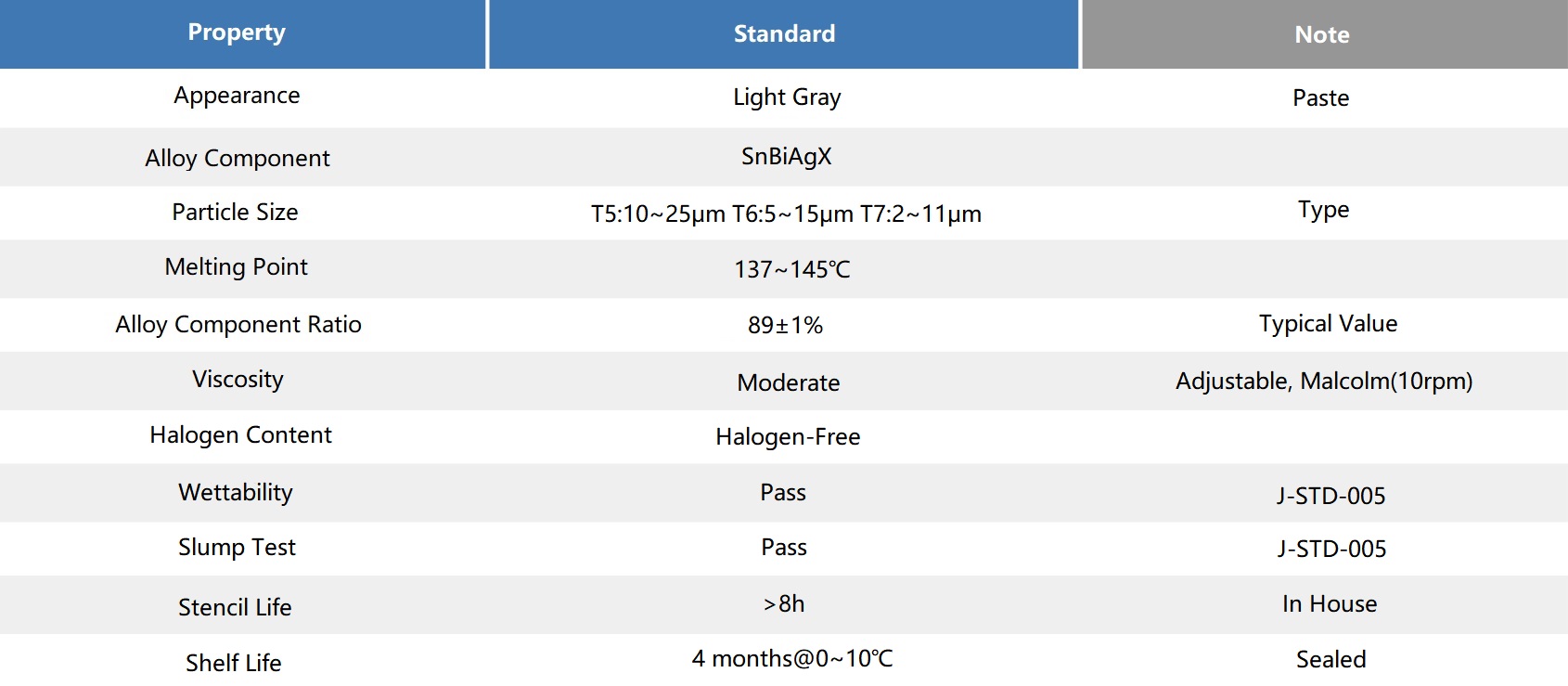

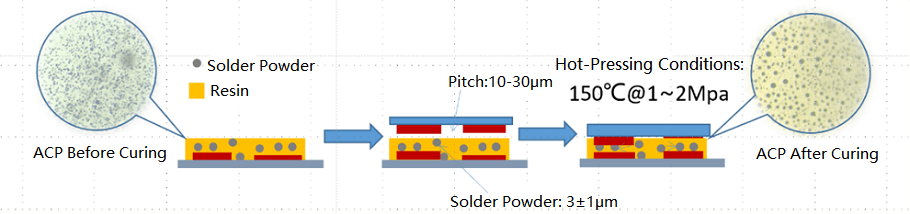

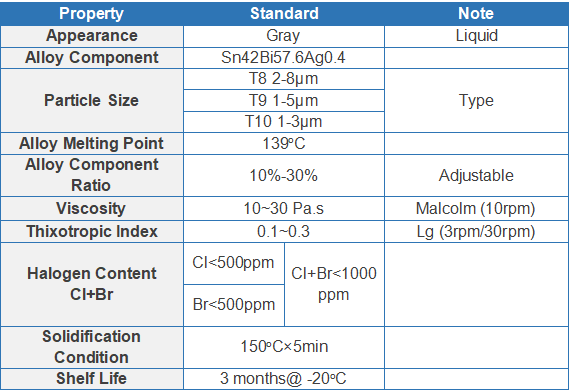

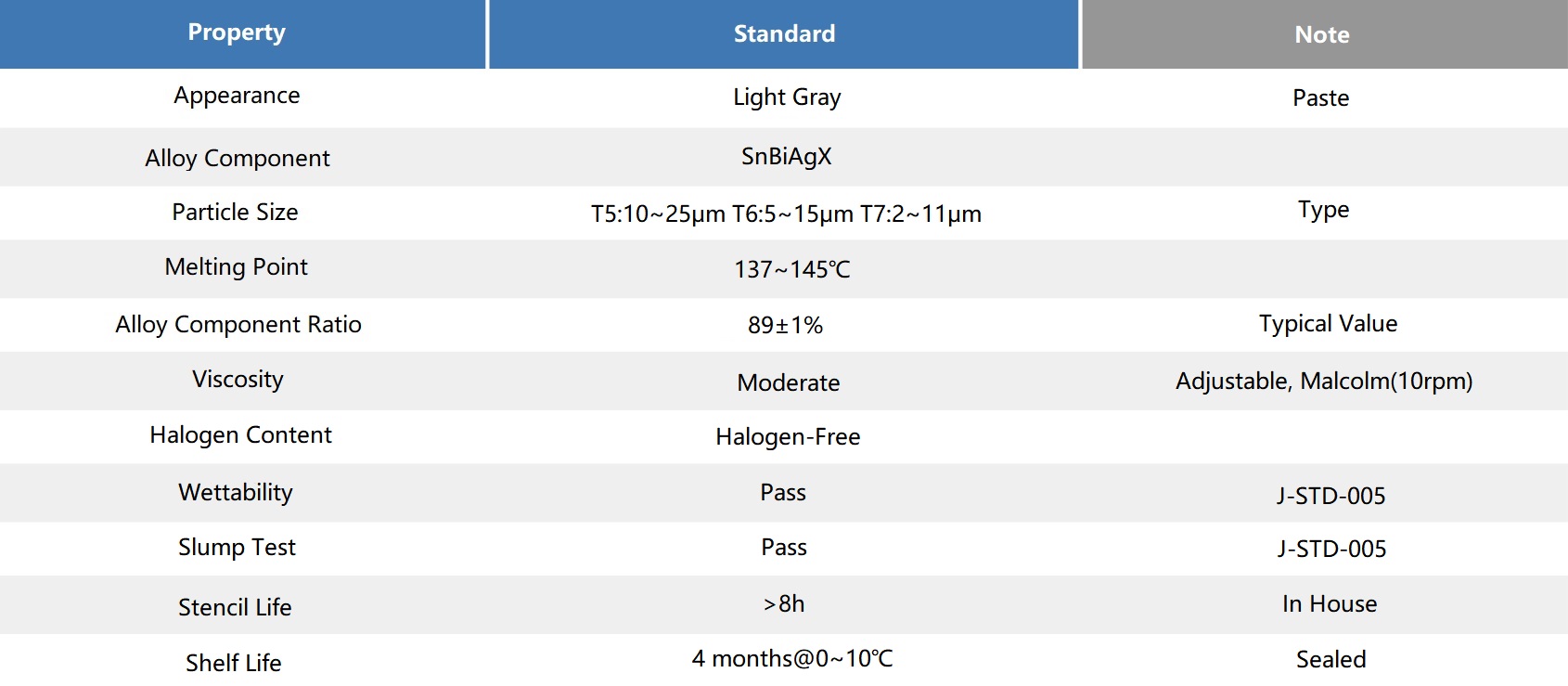

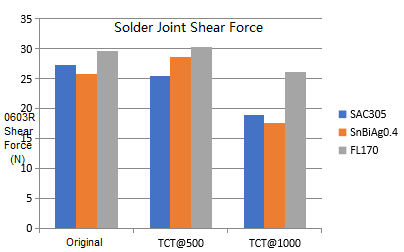

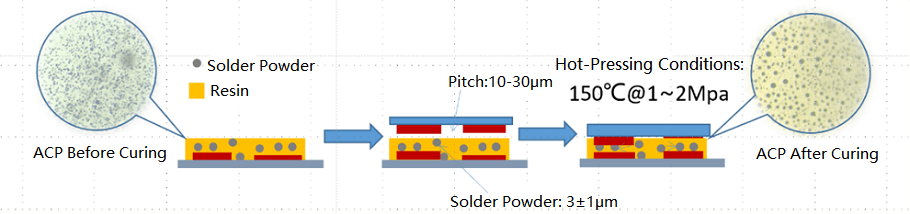

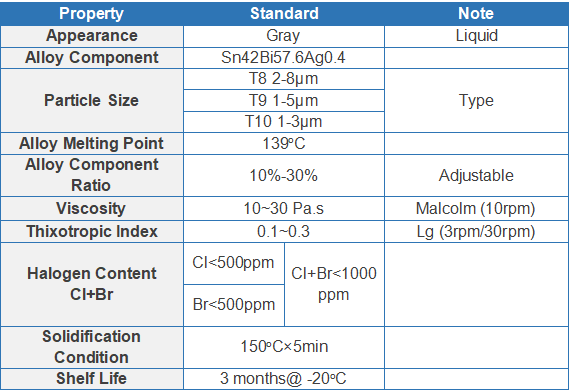

FACA-138D series is a low-temperature metallurgical-bonding halogen-free anisotropic conductive paste (ACP). The main alloy component of FACA-138D is SnBiAg0.4. Fitech classifies solder powders into T8 powder (2-8um), T9 powder (1-5um), and T10 powder (1-3um) based on particle sizes. Solder powder and epoxy-based flux are combined to produce a low-temperature conductive paste.

1. The conductive filler has uniform particle size, and FACA-138D has outstanding dispersion performance;

2. After hot-pressing solidification, the bonding of insulated materials increases soldering reliability;

3. There is no solvent volatilization during the hot-pressing curing process;

4. The hot-pressing temperature is low, and the solder powder melts and metallurgically connects with the pad, enhancing the bonding strength;

5. FACA-138D is an extraordinary anisotropic conductive solder that is longitudinal conductive and non-conductive in the transverse direction.

Before Curing:

1. Warming Instruction: Solder paste needs to be refrigerated, and the preferred temperature is 0-10℃. When taking out solder paste from the cold box, its temperature is much lower than the room temperature. If the bottle cap opens without rewarming, the water vapor in the air will easily condense and adhere to the solder paste. The high temperature exceeding 150℃ during soldering increases the vaporization rate of water, which may cause the phenomenon of "exploding solder" to produce solder balls and even damage the components.

2. Warming Method: The sealed solder paste should rewarm to room temperature naturally; Rewarm no more than twice.

3. Warming Time: Return to warm for 2 to 3 hours at room temperature. The actual time required to reach thermal equilibrium varies by vessel size.

4. Note: Do not open the bottle cap without sufficient rewarming or shorten the rewarming time by using heat sources.

5. Operating Environment: The best operating temperature and humidity are 20-25°C and 40-60%RH, respectively.