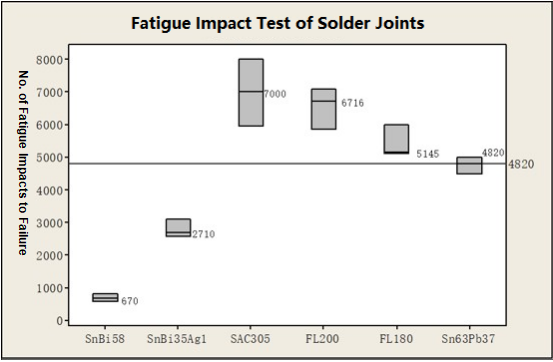

1. Product: Lead-free solder paste and lead-free epoxy solder adhesive;

2. Flux: No-clean and water-soluble types of rosin resin and epoxy resin;

3. Applications: Low-temperature and high-reliability soldering

4. Type: T6(particle size:5-15μm)-T9 (particle size:1-5μm);

5. Advantages: Micro-nano-enhanced low-temperature solder with high mechanical strength, reduce the problem of poor soldering caused by inconsistent expansion coefficients;

6. Processes: Printing, dispensing, needle transfer, and jetting;

8. Reflow under nitrogen protection (reflow oxygen content ≤100ppm).

FSA-170/180/200

FL-170/180/200

FSA-305

Description

FSA-170 series epoxy solder paste is made of low-temperature alloy solder powder FL170 with excellent sphericity, uniform particle size, low oxygen content, and halogen-free flux. The solvent evaporates very slightly during soldering and curing. There is no solder ball generation after soldering. The solder powder melts and shrinks, and the solder joints are metallurgical connections, which are equivalent to the soldering effects of solder paste. FSA-170 is a no-clean product. Solder residue becomes thermosetting adhesive around the solder joints to improve soldering strength, corrosion resistance, and insulation. FSA-170 is suitable for the reliable packaging of thin substrates and non-heat-resistance components.

Features

1. FSA-170 has excellent soldering strength with a peak reflow temperature of 170℃;

2. It is unnecessary to clean after soldering, and the residue becomes thermosetting adhesive to improve electric insulation and solder joint strength;

3. It has outstanding chemical activity and does not generate solder balls after soldering;

4. The operation is simple. Reflow oven, electric hot plate, and stove can be used;

5. It has advantages such as outstanding thixotropy, suitable viscosity, excellent stability, no delamination, and long operating life;

6. It has the functions of self-assembly and chip correction. When applying epoxy solder paste, the chip is automatically corrected when heating, and the solder automatically combines with the pad.

Description

FL170 is a low-temperature alloy solder powder with excellent sphericity, uniform particle size, low oxygen content, and high strength. It is combined with zero-halogen flux to produce FL-170 series low-temperature solder paste. Only a tiny amount of solvent volatilizes during the soldering process. There is no solder ball generation after soldering. The solder paste has outstanding residue minimization and wettability. The solder joints generated are solid, plump, and bright. FL-170 is ideal for low-temperature soldering, especially for low-temperature component mounting.

Features

1. Excellent soldering strength with a peak reflow temperature of 170℃;

2. Antimony-free, lead-free and environmental-friendly;

3. Outstanding thixotropy and appropriate viscosity available for jet printing, pin transfer, dispensing, printing, etc.;

4. Superior printing performance and stencil life because of stable viscosity and tack time over 12 hours;

5. Extraordinary soldering performance and proper wettability in different parts;

6. Less residue production after drying, no solder ball formation, and reliable solder joints.

Description

FSA-305 series epoxy solder paste is made of SAC305 solder powder with excellent sphericity, uniform particle size, and low oxygen content, and halogen-free flux. Only a tiny amount of solvent evaporates during soldering and curing. There is no solder ball generation after soldering. The solder powder melts and shrinks, and the solder joints are metallurgical connections, which have soldering effects equivalent to that of solder paste. Solder residue becomes thermoset adhesive and is attached around the solder joints to improve soldering strength, corrosion resistance, and insulation. FSA-305 is a no-clean product and is an excellent solder material for medium and high temperature soldering.

Features

1. FSA-305 can achieve metallurgical connection and has better thermal conductivity and electrical conductivity than that of silver conductive paste;

2. It does not require washing after soldering, and the residue turns to thermosetting adhesive to promote electrical insulation;

4. It has excellent chemical activity and solder ball elimination performance;

4. The operation is simple, and the equipment such as reflow ovens, electric hot plates, and stoves can be used;

5. It has advantages of excellent thixotropy, appropriate viscosity, outstanding stability, no delamination, and long stencil life;

6. It has the functions of self-assembly and chip correction. When applying epoxy solder paste, the chip is automatically corrected when heating, and the solder automatically combines with the pad.