FL170/180/200 Series Micro-Nano Particle Reinforced Low Temperature High Strength Solder

FL170/180/200 Series Micro-Nano Particle Reinforced Low Temperature High Strength Solder

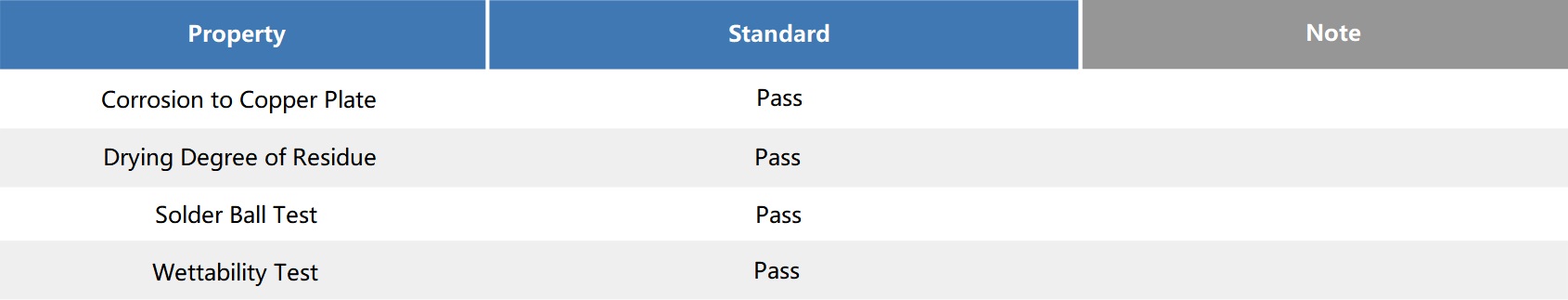

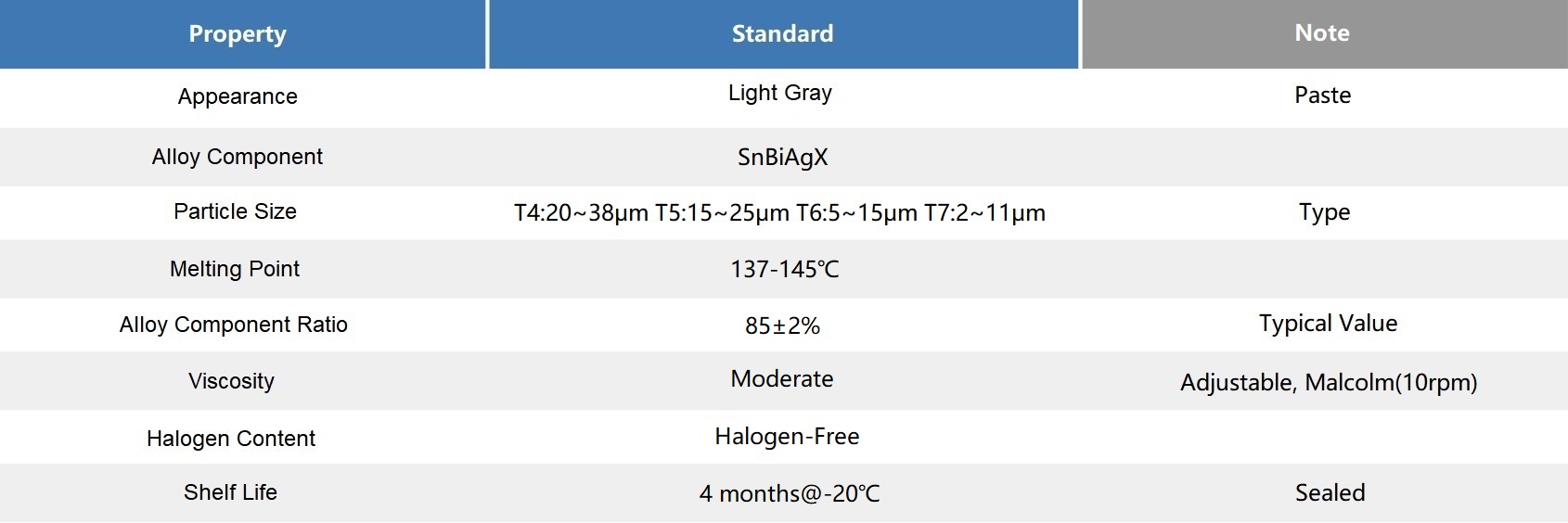

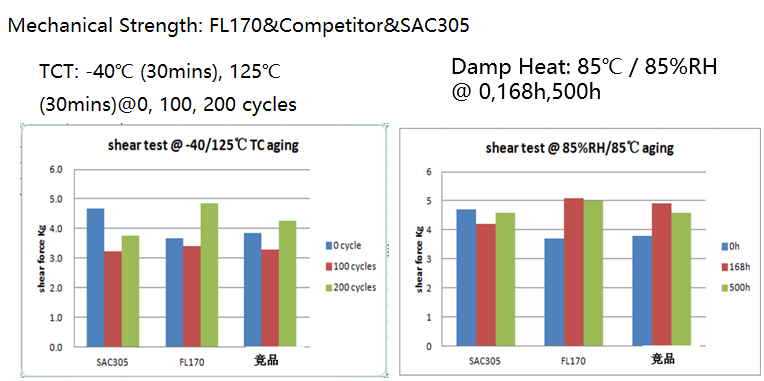

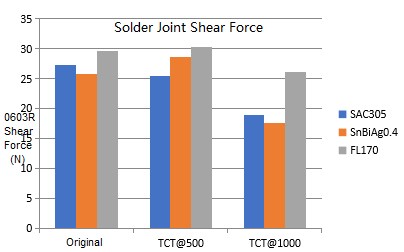

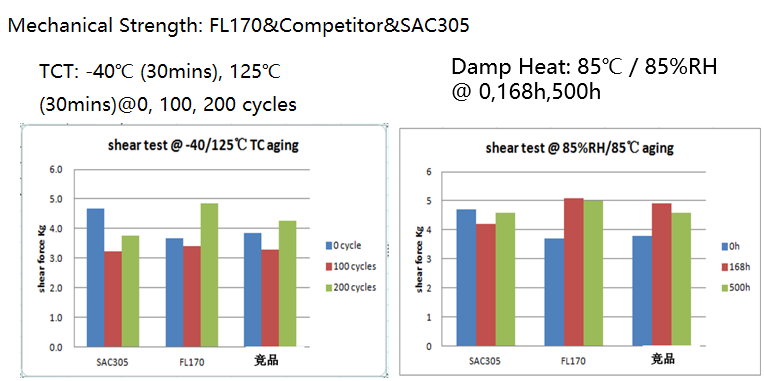

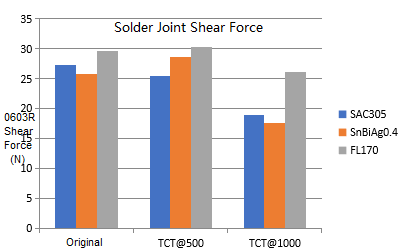

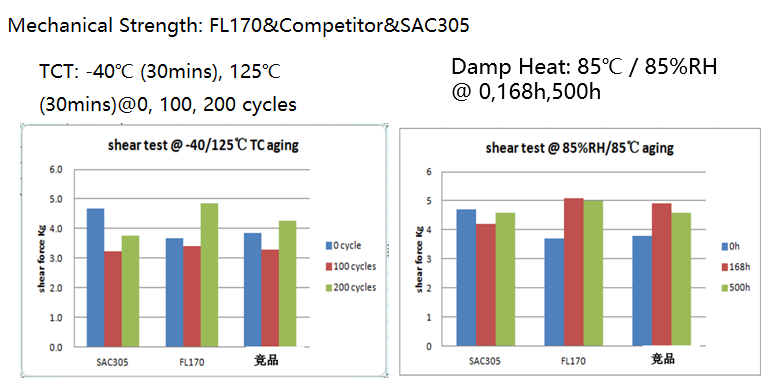

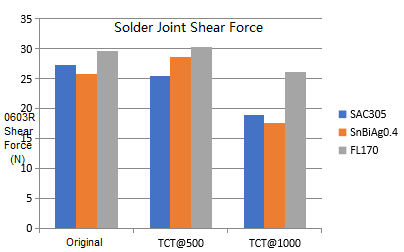

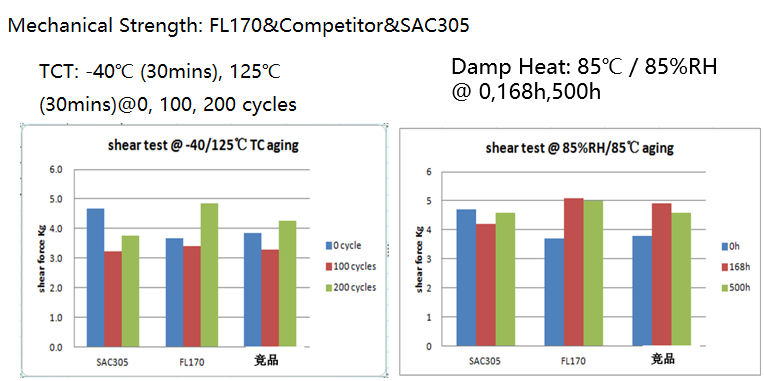

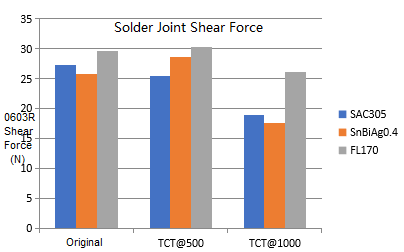

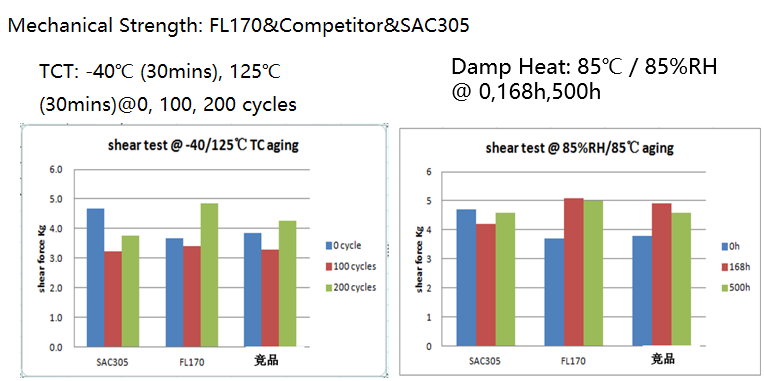

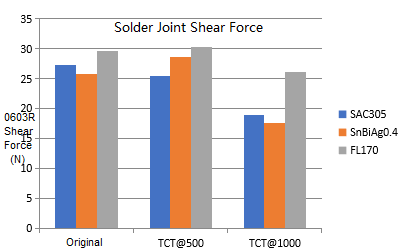

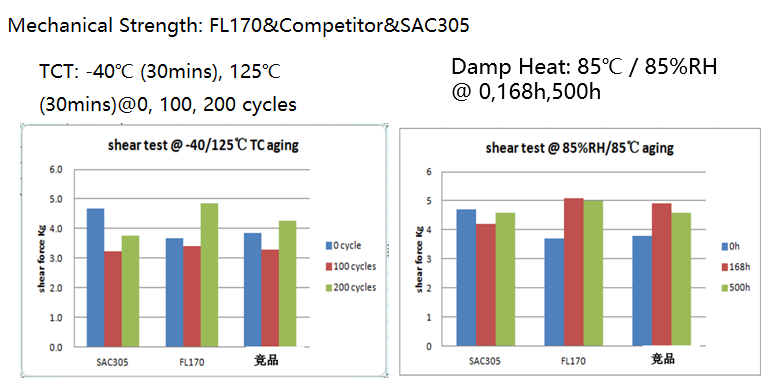

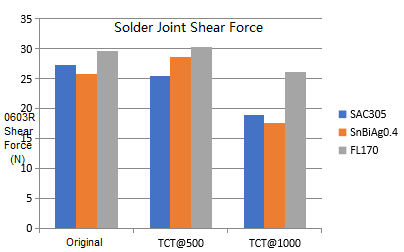

The use of micro- and nano-enhanced particles dispersed in the solder refines the organisational structure and inhibits the enrichment of Bi, whose reliability is significantly improved.

Can achieve 170~200℃ low temperature welding, suitable for non-heat-resistant components and thin substrate chips.

Wide range of uses, can be used for printing, dispensing, needle transfer, dip glue, spray printing and other processes.

Particle size range T5 to T8, suitable for various solder joint spacing.The product has been patented in the United States and Japan.

FSA-170D

FSA-170P

FTD-170

FTP-170

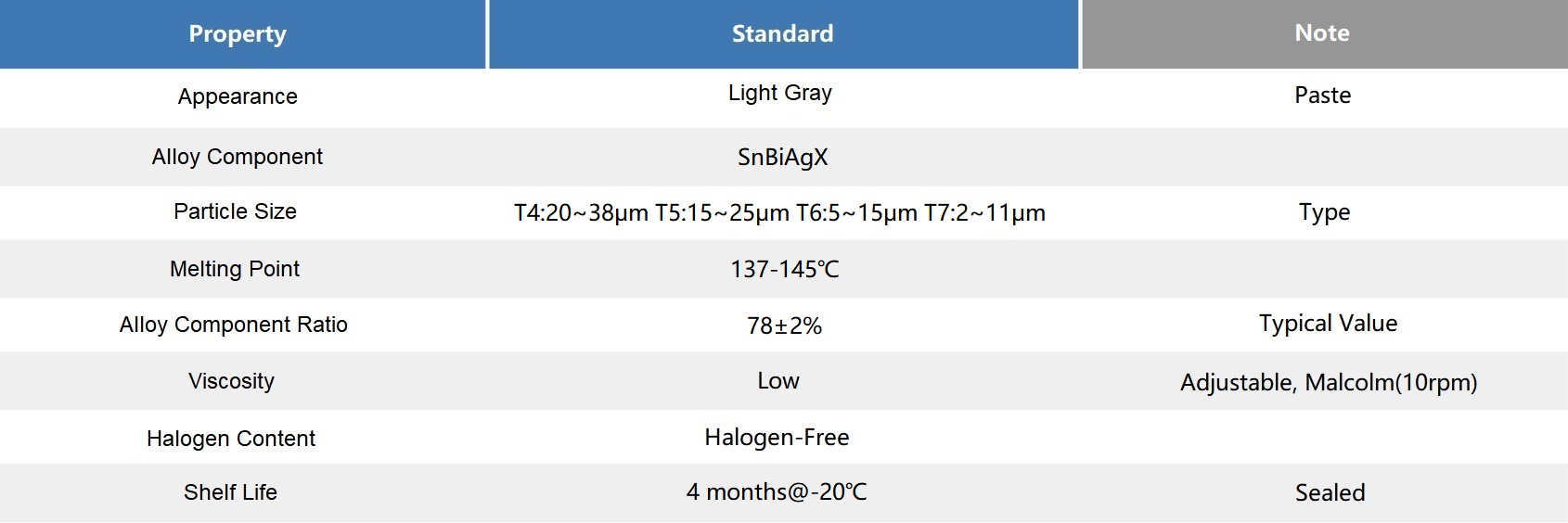

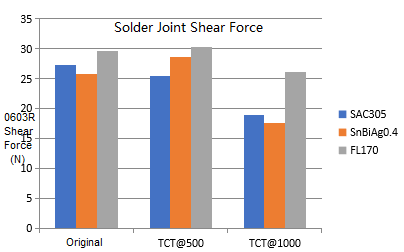

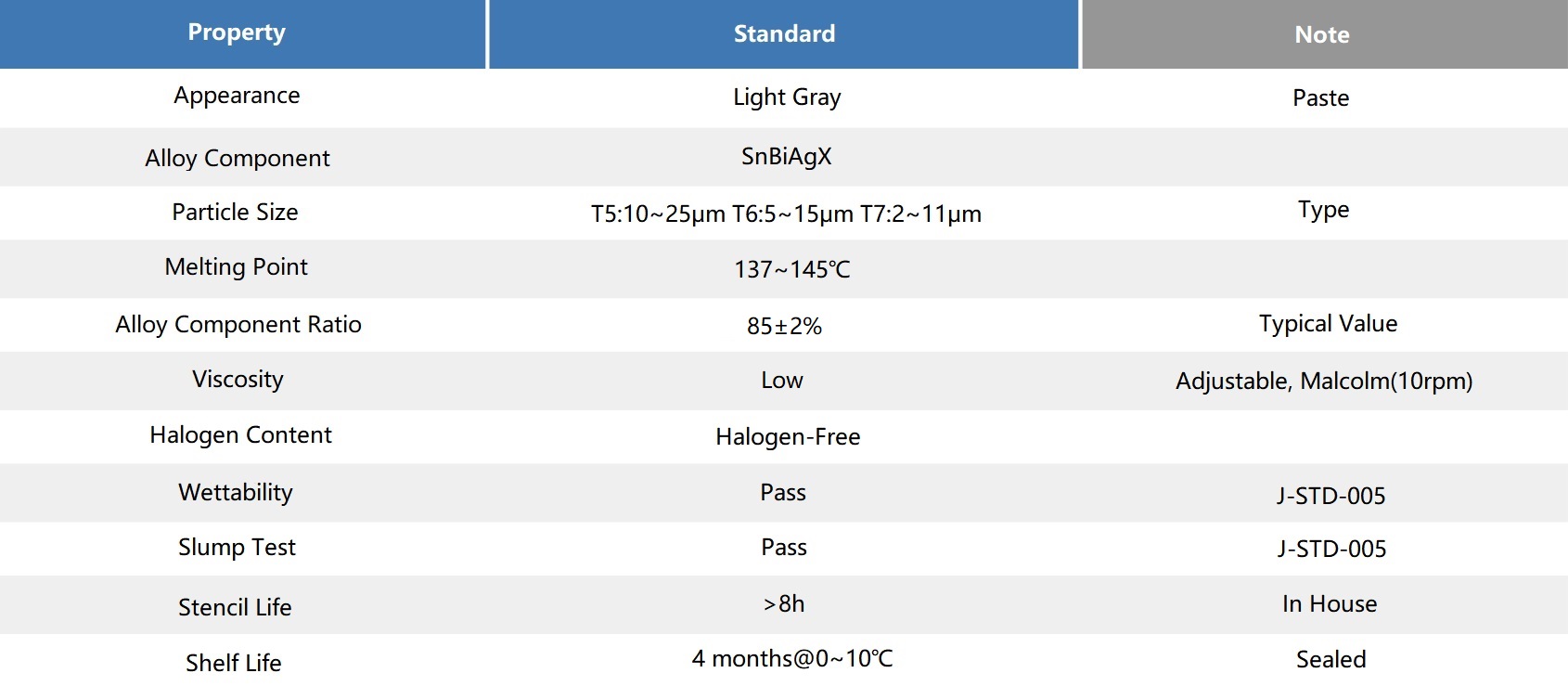

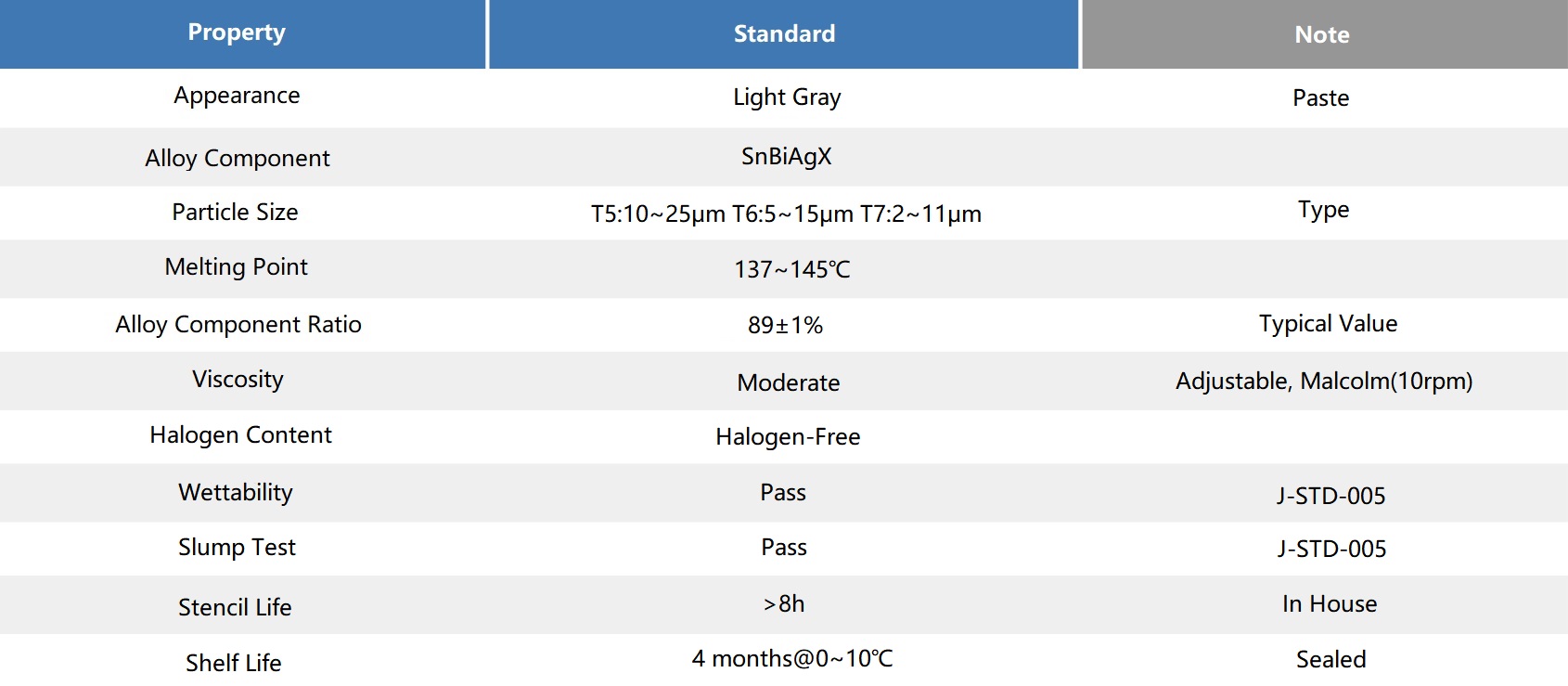

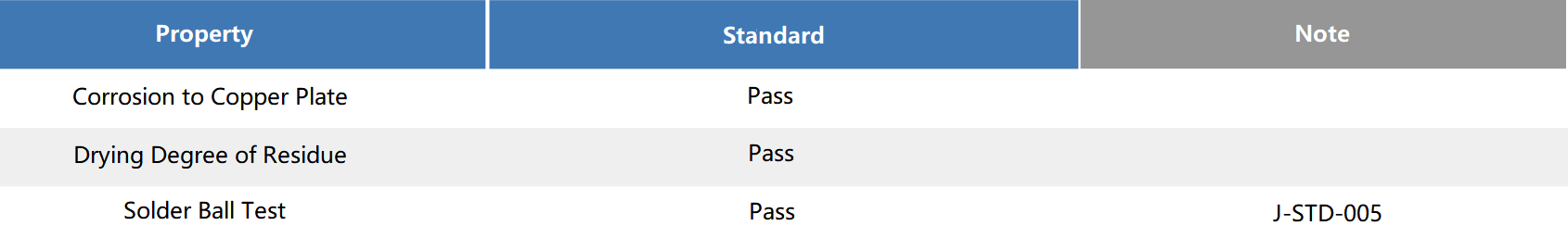

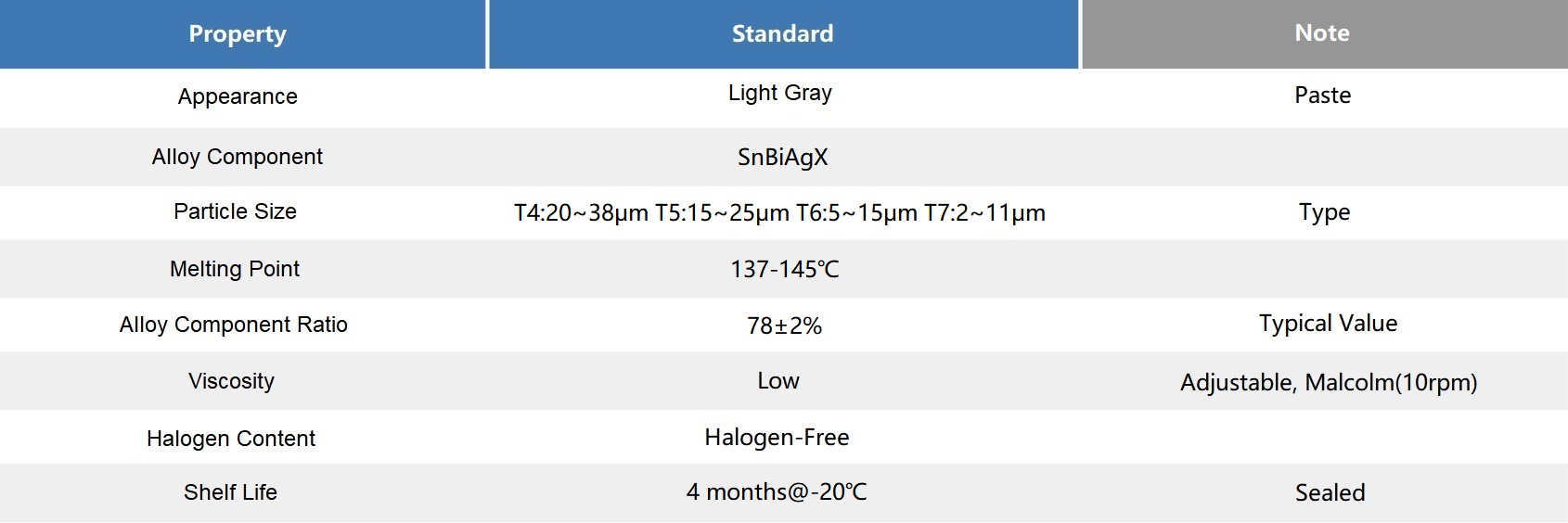

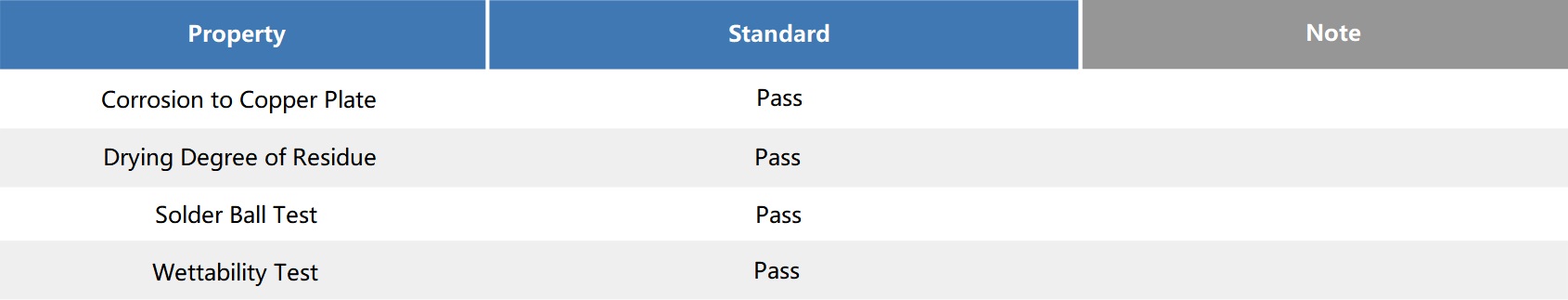

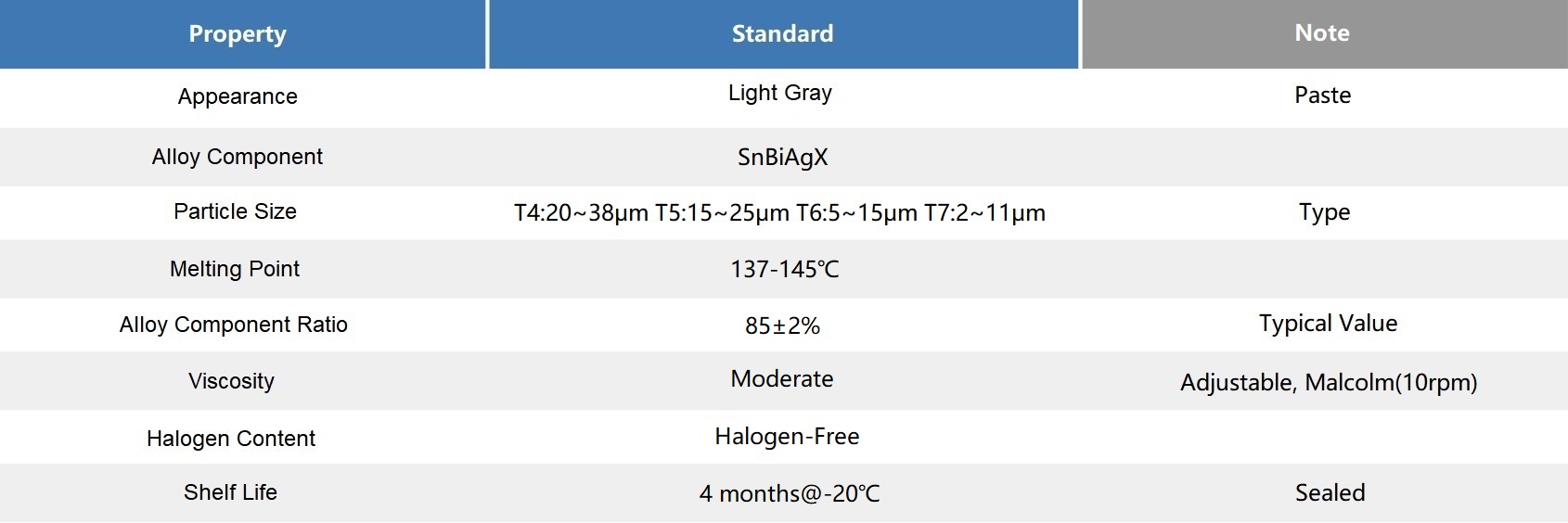

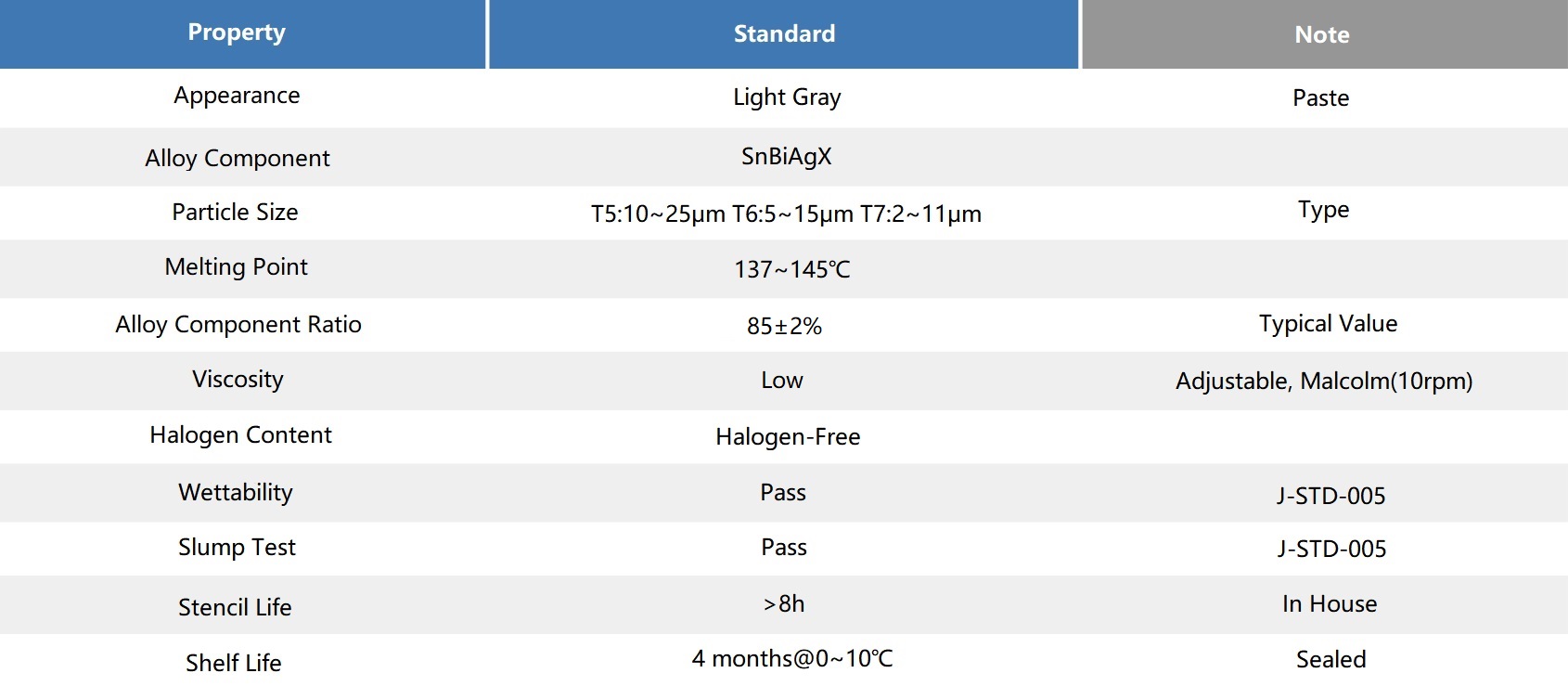

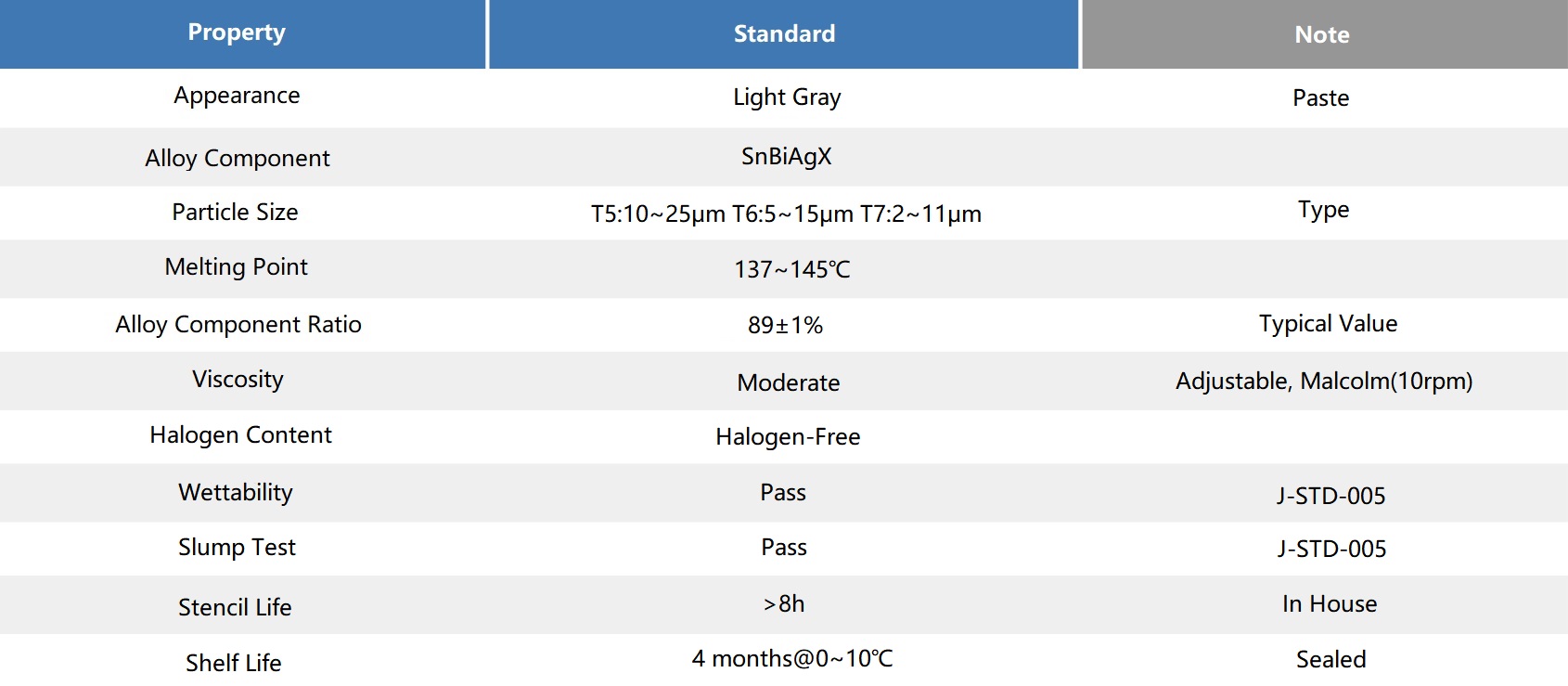

The main alloy component of FSA-170D series epoxy solder paste is Fitech’s FL170 low-temperature alloy solder powder (SnBiAgX). Fitech classifies FL170 solder powders into T4 to T7 based on particle sizes. The solder powder and epoxy-based flux are formulated into superior low-temperature high-reliability solder paste.

1. Excellent sphericity, uniform particle size, low oxygen content, and high strength;

2. Reduce solvent volatilization during the solidification process;

3. Halogen-free formula;

4. Reduce solder ball formation after soldering;

5. The solder joints are metallurgically connected, which are equivalent to the soldering effects of solder paste;

6. The soldering residue becomes thermosetting adhesive, which is attached around the solder joint to improve its strength and enhance the anti-corrosion and insulation performance;

7. No cleaning necessary;

8. It is suitable for reliable packaging of thin substrates and non-heat-resistant components.

Warming Method: The sealed solder paste should rewarm to room temperature naturally; Rewarm no more than twice.

Warming Time: Rewarm 2 to 3 hours at room temperature. The actual time required to reach thermal equilibrium varies by vessel size.

Note: Do not open the bottle cap without sufficient rewarming or shorten the rewarming time by using heating equipment.

Operating Environment: The best operating temperature and humidity are 20-25°C and 40-60%RH, respectively. Reflow soldering in a nitrogen atmosphere is recommended.

Stencil Cleaning Solvent: Ether. Propylene glycol monomethyl ether (PM) is preferred.

FSA-170P (180P/200P) series low-temperature lead-free high reliable solder adhesive (epoxy solder paste) products are composed of low-temperature alloy solder powder and halogen-free flux. Only a tiny amount of solvent evaporates during the soldering and curing process. There is no solder ball generation after soldering. The solder powder melts and shrinks, and the solder joints are metallurgical connections, which are equivalent to the soldering effect of solder paste. FSA-170P epoxy solder paste is unnecessary to clean. The solder residue becomes thermosetting adhesive to reinforce the solder joint and enhance the anti-corrosion and insulation performance. The product is suitable for the reliable packaging of thin substrates and non-heat-resistance components.

Warming Method: The sealed solder paste should rewarm to room temperature naturally; Rewarm no more than twice.

Warming Time: Rewarm 2 to 3 hours at room temperature. The actual time required to reach thermal equilibrium varies by vessel size.

Note: Do not open the bottle cap without sufficient rewarming or shorten the rewarming time by using heating equipment.

Operating Environment: The best operating temperature and humidity are 20-25°C and 40-60%RH, respectively. Reflow soldering in a nitrogen atmosphere is recommended.

Cleaning Instruction: There is a small amount of residue around the pad after reflow, which should be cleaned with deionized water as soon as possible. The temperature of deionized water is between 25°C and 40°C.

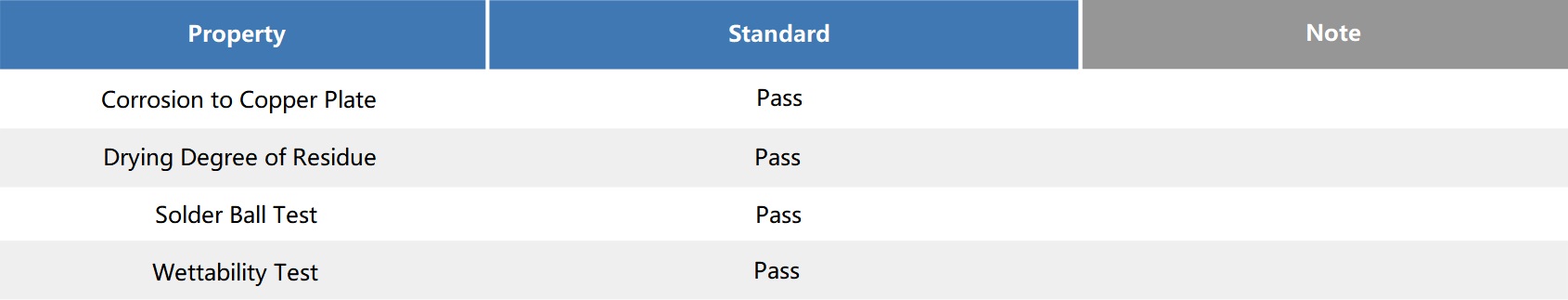

Low-temperature FL170 alloy solder powder with good sphericity, uniform particle size, low oxygen content, and high strength are combined with zero-halogen flux to produce FTD-170 series low-temperature solder paste. Only a small amount of solvent volatilizes during the soldering process. There is no solder ball formation after soldering. The solder paste has excellent performance of residue minimization and wettability. The solder joints generated are strong, plump, and bright. FTD-170 is ideal for low-temperature soldering, especially for low-temperature component mounting.

1. Warming Instruction: Solder paste needs to be refrigerated, and the preferred temperature is 0-10°C. When taking out the solder paste from the cold box, its temperature is much lower than the room temperature. If the bottle cap is opened without rewarming, the water vapor in the air will easily condense and adhere to the solder paste.The high temperature exceeding 150°C during soldering increases the vaporization of water, which may cause the phenomenon of "exploding solder" to produce solder balls and even damage the components.

2. Warming Method: The sealed solder paste should rewarm to room temperature naturally; Rewarm no more than twice.

3. Warming Time: Return to warm for 2 to 3 hours at room temperature. The actual time required to reach thermal equilibrium varies by vessel size.

4. Note: Do not open the bottle cap without sufficient rewarming or shorten the rewarming time by using heat sources.

5. Operating Environment: The best operating temperature and humidity are 20-25°C and 40-60%RH, respectively. Reflow soldering in a nitrogen atmosphere is recommended.

6. Operating Time

① Continuous printing time: When adding solder paste continuously: 8 hours; In case of discontinuous addition of solder paste: 4 hours; ② Please add solder paste before the solder paste on the board is almost one third (rolling diameter: 10mm or less); ③ Please keep the solder paste on the plate within 3 hours; ④ If printing is interrupted for more than 30 minutes, please clean the stencil. ⑤ Dwell time after printing: After the solder paste is printed, the components should be mounted as soon as possible and the soldering should be completed when passing the oven to avoid drying out the surface of the solder paste due to long storage, which will affect the component mounting and soldering effects. Generally, the recommended dwell time of solder paste is no more than 4 hours, while the low-temperature bismuth-containing solder paste does not exceed 2 hours. If the printing is interrupted for more than 30 minutes or is temporarily interrupted, the printing template needs to be cleaned. It can continue to work after 1-2 trial printing. The solder paste attached to the narrow space of the opening (≤0.4mm) and the opening of the stencil will gradually dry, which will degenerate the adhesive ability.

Low-temperature FL170 alloy solder powder with excellent sphericity, uniform particle size, low oxygen content, and high strength are combined with zero-halogen flux to produce FTP-170 series low-temperature solder paste. Only a small amount of solvent volatilizes during the soldering process. There is no solder ball formation after soldering. In addition, FTP-170 has an excellent performance in residue minimization and wettability. The solder joints generated are strong, plump, and bright. The product is ideal for low-temperature soldering, especially for low-temperature component mounting.

1. Warming Instruction: Solder paste needs to be refrigerated, and the preferred temperature is 0-10°C. When taking out the solder paste from the cold box, its temperature is much lower than the room temperature. If the bottle cap is opened without rewarming, the water vapor in the air will easily condense and adhere to the solder paste.The high temperature exceeding 150°C during soldering increases the vaporization of water, which may cause the phenomenon of "exploding solder" to produce solder balls and even damage the components.

2. Warming Method: The sealed solder paste should rewarm to room temperature naturally; Rewarm no more than twice.

3. Warming Time: Return to warm for 2 to 3 hours at room temperature. The actual time required to reach thermal equilibrium varies by vessel size.

4. Note: Do not open the bottle cap without sufficient rewarming or shorten the rewarming time by using heating equipment.

5. Operating Environment:The best operating temperature and humidity are 20-25°C and 40-60%RH, respectively. Reflow soldering in a nitrogen atmosphere is recommended.

6. Operating Time

① Continuous printing time: When adding solder paste continuously: 8 hours; In case of discontinuous addition of solder paste: 4 hours; ② Please add solder paste before the solder paste on the board is almost one third (rolling diameter: 10mm or less); ③ Please keep the solder paste on the plate within 3 hours; ④ If printing is interrupted for more than 30 minutes, please clean the stencil. ⑤ Dwell time after printing: After the solder paste is printed, the components should be mounted as soon as possible and the soldering should be completed when passing the oven to avoid drying out the surface of the solder paste due to long storage, which will affect the component mounting and soldering effects. Generally, the recommended dwell time of solder paste is no more than 4 hours, while the low temperature bismuth-containing solder paste does not exceed 2 hours. If the printing is interrupted for more than 30 minutes or is temporarily interrupted, the printing template needs to be cleaned. It can continue to work after 1-2 trial printing. The solder paste attached to narrow space of the opening (≤0.4mm) and the opening of the stencil will gradually dry, which will degenerate the adhesive ability.

FL170/180/200 Series Micro-Nano Particle Reinforced Low Temperature High Strength Solder

FL170/180/200 Series Micro-Nano Particle Reinforced Low Temperature High Strength Solder