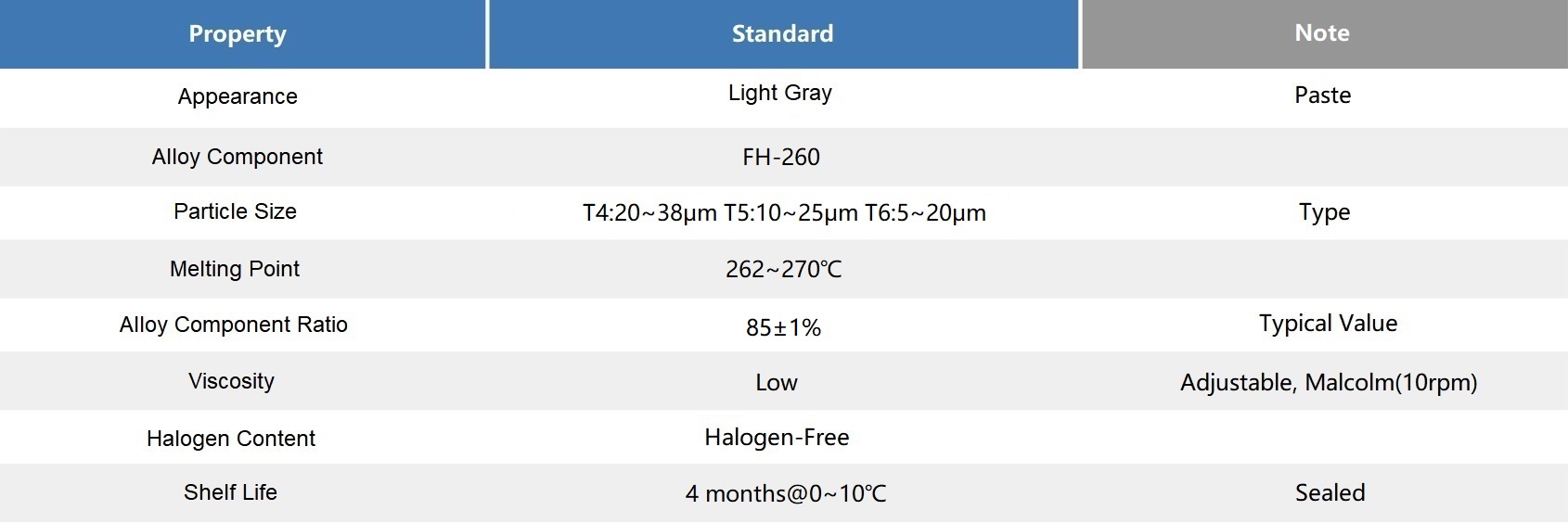

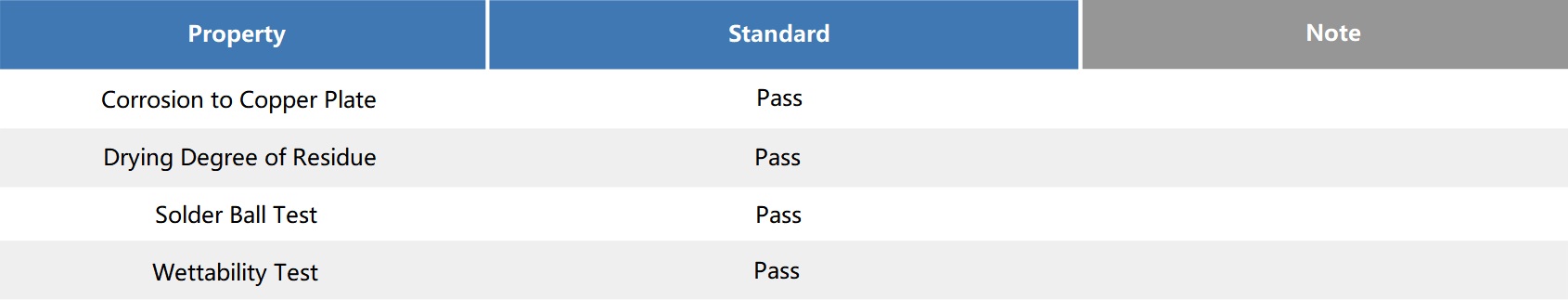

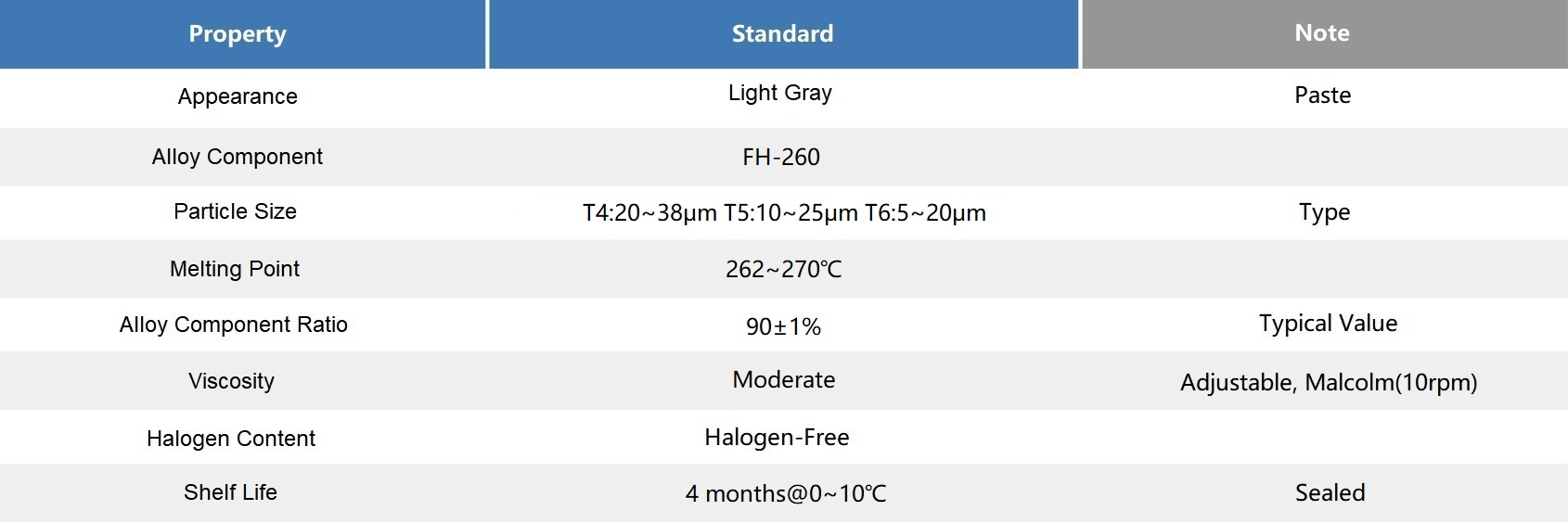

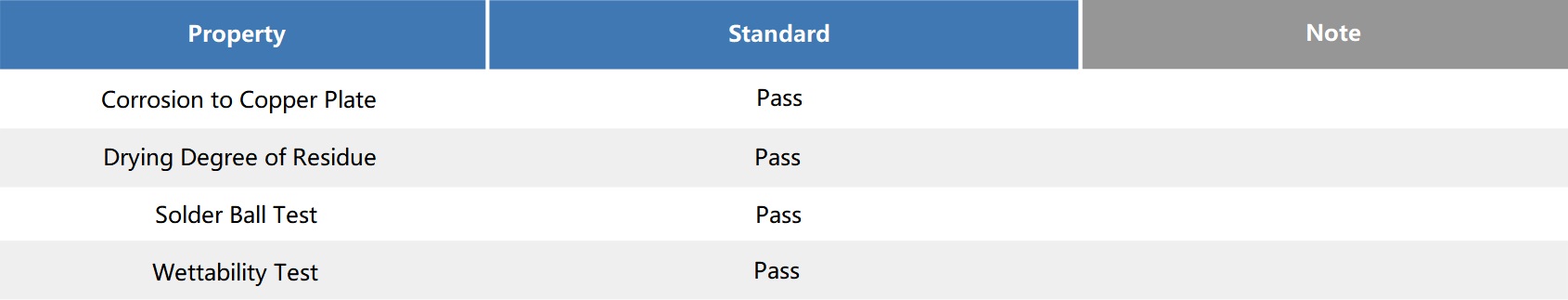

High-temperature lead-free solder paste is a lead-free solder paste with a minimum alloy melting point of 260°C, which is suitable for multiple reflow soldering of power semiconductor packaging and microelectronic packaging. Fitech adopts FH260 solder powder with excellent sphericity, uniform particle size and low oxygen content, and excellent halogen-free flux to produce secondary reflow solder paste, which meets the RoHS environmental protection standards. FH-260 product covers a wide range of particle sizes from T4 to T6, making it applicable to printing (FH-260P series) and dispensing (FH-260D series) processes. FH260 is synthesized based on bismuth elements by adding reinforced micron/nanoparticles, successfully replacing high-lead solder paste, and meeting RoHS environmental protection standards. Different solder powder particle sizes and metal contents can be provided to satisfy various customers’ requirements for products and processes.

-

PRODUCTS

- ULTRA-FINE SOLDER PASTE

- ULTRA-FINE EPOXY SOLDER PASTE

- GOLD-TIN SOLDER PASTE

- SOLDER PASTE FOR MULTIPLE REFLOW SOLDERING

- LASER SOLDER PASTE

- WATER-SOLUBLE SOLDER PASTE

- JETTING SOLDER PASTE

- FLUX

- HIGH/LOW TEMPERATURE SOLDER PASTE

- LEAD-FREE SOLDER PASTE

- ULTRA-FINE SOLDER POWDER

- LOW ALPHA SOLDER PASTE/SOLDER POWDER

- SMT SOLDER POWDER

- CUSTOMIZED PACKAGING SOLDER

- APPLICATIONS

- MARKET AREA

- TECHNICAL SUPPORT

- NEWS

- ABOUT US