Fitech’s Ultra-Fine Solder Paste Improves Ultra-Fine-Pitch Soldering Efficiency

1. Ultra-Fine Solder Paste - New Challenges for New Display Packaging

Since last year, ultra-fine-pitch LED display has contributed significantly to the output value and has been highly valued by the industry. Soldering yield and efficiency face new challenges as die size, pad size, and pixel pitch decrease. Fitech’s ultra-fine solder paste improves the efficiency of ultra-fine-pitch soldering.

On April 14th, at the Ultra-fine-pitch Display LED Technology Innovation Application Conference, Xu Pu, general manager of Shenzhen Fitech, shared the "Ultra-Fine Soldering Materials for Ultra-Fine-Pitch LED Display Micro-connection", and elaborated on the effects of ultra-fine solder on improving the soldering yield and ensuring the impact of quality.

Mr. Xu Pu, the general manager of Fitech

2.The Miniaturization of Chip Brings New Requirement for Solder Paste

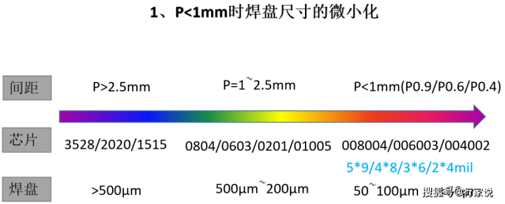

When the pitch is less than P1.0, the pad size will be smaller, which will bring challenges to the solder particle size, stencil, and solder applications (the solder paste printing takes a long time for the subsequent solidification process and requires excellent solder characteristics. The reflow soldering and curing process are different from other common processes).

Pixel pitch, chip size, and pad size.

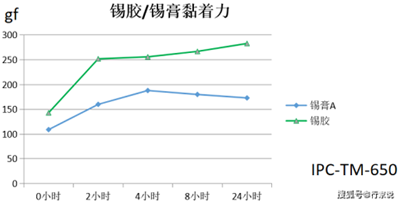

Solder paste/epoxy solder paste tackiness.

3. Fitech’s Ultra-Fine Solder Paste/Epoxy Solder Paste - Ultra-Fine-Pitch Soldering Solution

Mr. Xu Pu said that Fitech’s patented epoxy solder paste products have excellent chip adhesion, which can ensure the timeliness of the later massive chip transfer process and meet the needs of different chip transfer processes. Fitech’s ultra-fine solder powder is perfectly rounded, with a smooth surface and stable rheological properties of the same volume of particles, which ensures the stability of solder paste and the service life of dispensing and printing equipment.

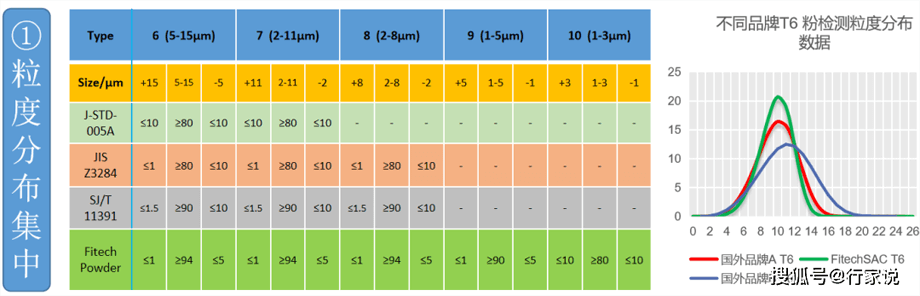

In order to improve the uniformity and precision of solder paste printing, the solder powder is usually required to have a uniform particle size, narrow particle size distribution (the number of particles in its upper and lower limits should not exceed 10%), high sphericity (the aspect ratio of the powder should not exceed 1.2:1), low oxygen content, and good oxidation resistance.

Solder powder size distribution.

1. Fitech’s solder paste / epoxy solder paste product characteristics

Fitech’s unique powdering and sorting technology make the particle size concentration of ultra-fine solder powder better than IPC and JIS indicators. Fitech took the lead in developing and mass-producing T9.T10 ultra-fine solder powder to meet the requirements of ultra-fine-pitch LED display packaging technology.

General Manager Xu Pu introduced that the self-assembly solder is suitable for the new mini/microLED display package. The packaged devices are small and regularly distributed, and the pads are highly consistent. The self-assembly gap is 10μm~100μm, and the solder deposit area accounts for at least 1/3 of each pad area. According to the chip size and pad distribution, the self-assembly solder formula can be designed, including metal type, proportion, viscosity, etc.

5. Outlook

Mr. Xu Pu finally concluded that the industry is now entering the era of ultra-fine-pitch LEDs. In order to promote the development of the industry, Fitech will continue to explore new, reliable, and fast heating methods to improve packaging efficiency and yield, reduce the cost of ultra-fine-pitch LED packaging process, and help ultra-pitch products enter the market faster.

-End-

*Disclaimer: Except for "reprinted" articles, the copyright of the original content published on this site belongs to Shenzhen Fitech. Without consent and authorization, it may not be reproduced, reproduced, quoted, changed, or published. This article is originally created by the author, and the content of the article is the author's personal opinion. "Reprint" is only to convey a different point of view and does not mean approval or support for the point of view. If there is any infringement, please contact us, and we will delete it!

Back to list

Back to list