Fitech‘s Lead-Free Solder Paste Solutions for Secondary Reflow Soldering

Abstract

Fitech proposed a new secondary reflow solution for microelectronics and semiconductor packaging based on the company's patent. It is designed to use ordinary SAC305 solder paste or SAC0307 solder paste at the first soldering of secondary reflow soldering. FL series low-temperature high-strength solder paste is used at the second soldering of secondary reflow soldering. The strength of the solder joint is similar to that of the SAC solder paste series alloy, which perfectly solves the problem of the lead-free solder paste alloy selection for the secondary reflow of components and circuit boards. Similarly, it is a perfect solution for circuit boards that require double-sided secondary reflow.

Key Words

Secondary reflow soldering, lead-free solder paste, high-strength low-temperature lead-free solder, reflow profile & solution

1. Secondary reflow process puts forward requirements for lead-free solder paste

Many components and circuit boards encounter problems during secondary reflow when using solder paste in the microelectronics and semiconductor packaging industry. For example, after the chip or component is packaged and soldered, the components need to be connected to the circuit boards by the second reflow soldering. In addition, after some components are soldered on one side of the circuit board, other components must be soldered on the other side, which should perform secondary soldering. The problem is that the solder pastes used for secondary reflow soldering cannot have the same soldering temperatures. However, they should have the same or similar soldering strength. The traditional solder for secondary reflow is high-lead solder paste, such as Pb92.5Sn5Ag2.5, with the first reflow soldering temperature of 290-310℃. If the components are soldered on the circuit boards by secondary reflow, whether using SAC305 lead-free solder paste, Sn63Pb37 leaded solder paste, or Bi58Sn42 low-temperature lead-free solder paste, the peak reflow temperatures will not exceed the melting point of high-lead solder paste. This is the reason why high-lead solder pastes are still exempted in some areas when the global solder has been lead-free for 20 years.

With the miniaturization of artificial intelligence, the Internet of Things, and wearable electronic products, the international microelectronics and semiconductor packaging industry and even the military industry have higher requirements for lead-free products. The application of high-lead solder paste product Pb92.5Sn5Ag2.5 will be gradually limited, which puts forward urgent requirements for high-temperature lead-free solder paste. It has become a hot spot in the microelectronics and semiconductor packaging solder industry.

2. Traditional lead-free solder paste solution and its disadvantages for the secondary reflow soldering

Due to the constraints of the metal phase, limited types of solder paste alloys can be selected by the solder industry. In the lead-free high-temperature range, the alloys available are SnSb10 solder paste (melting point: 242-255℃), SnSb5 solder paste (melting point: 245°C), and BiAgX solder paste (melting point: 262°C). However, Antimony (Sb) is also restricted in the West because it is regarded as a heavy metal harmful to the human body. Moreover, the melting points of SnSb10 and SnSb5 solder pastes are only less than 20°C higher than that of commonly used SAC305 solder paste and SAC0307 solder paste. Since SnSb10 and SnSb5 solder powders are not eutectic, and both have a certain melting range (solidus and liquidus do not overlap), the application of these solder powders is not widely recognized. BiAgX solder paste has a melting point of 262°C, which has exceeded the peak reflow temperature of the SAC solder paste series (255°C). It is also a lead-free solder paste, which can meet the temperature requirements of the secondary reflow. However, this alloy is bismuth base, leading to poor heat transfer performance, which can be used only on some specific occasions to meet the requirements of secondary reflow.

Regarding solving the temperature problem of lead-free solder in the secondary reflow, the traditional idea is to find alloys with melting points higher than the peak reflow temperatures of the existing SAC solder paste series alloys. Indeed, people have found an ideal eutectic alloy consisting of Au80Sn20. Gold-tin solder paste has a melting point of 280℃. It has excellent strength and high reliability. It has been applied to high-end optoelectronic components and military fields. Its high price makes it unable to be widely used in consumer electronics.

3. Fitech's secondary reflow solder paste solution based on high-strength low-temperature lead-free solder paste

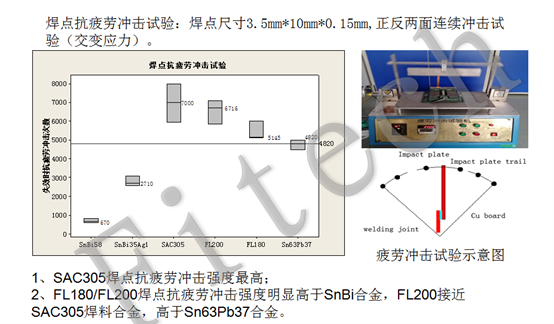

Fitech developed the FL series low-temperature high-strength solder paste alloy based on its patent called "micron/nanoparticle reinforced composite solder and its preparation method 201711280945.3", which proposed a brand new secondary reflow scheme for microelectronics and semiconductor packaging. The peak reflow temperature of FL series low-temperature high-strength solder alloys does not exceed 200℃. The solder joints are mainly made of tin-bismuth alloy and reinforced by micro/nanoparticles, which have soldering strength equivalent to 80-90% of SAC305. The fatigue resistance experiment of different types of alloy solder joints is shown in Figure 1.

Figure1. The fatigue resistance experiment of different types of solder paste alloy solder joints

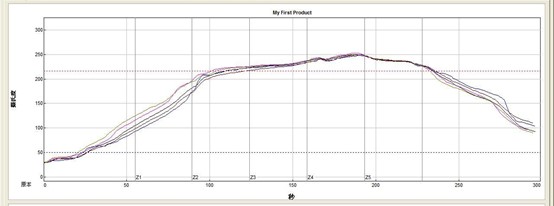

Ordinary SAC305 solder paste or SAC0307 solder paste can be used at the first soldering of secondary reflow soldering. The peak reflow temperature is 245-260°C. Figure 2 below shows the reflow curves of Fitech’s FTP-305 ultra-fine solder paste. Compared with the high-temperature solder Pb92.5Sn5Ag2.5, the temperature is reduced by more than 50℃.

Figure 2. The reflow curves of Fitech’s FTP-305 ultra-fine solder paste

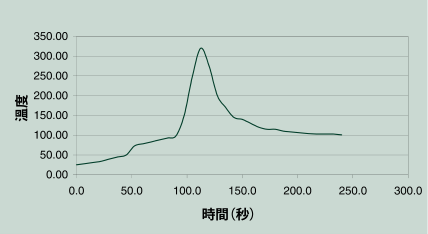

Figure 3. The reflow profile of the mainstream high-lead solder paste in the market

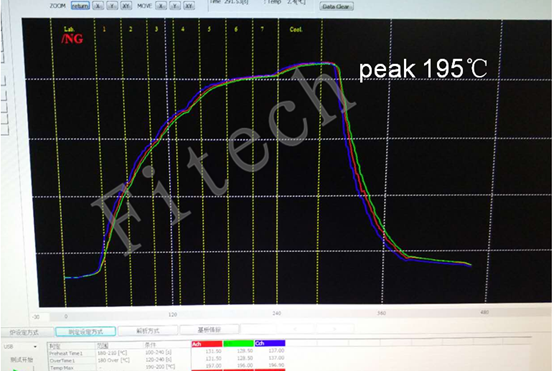

Figure 3 shows the reflow profile of the mainstream high-lead solder paste in the market. The SAC solder paste series have been used in the industry for more than 20 years. Its reliability has been tested and practiced. The patented FL low-temperature high-strength tin-bismuth eutectic solder alloy developed by Fitech is used at the second soldering of secondary reflow soldering. The peak reflow temperature of FL solder alloy is 190-200℃. The reflow profile of Fitech’s FL200 low-temperature high-strength solder is shown in Figure 4. It can be obtained that the secondary reflow of the FL200 solder does not affect the temperature of the solder joints formed by the first reflow. The strength of the solder joints formed by the secondary reflow has a soldering strength similar to that of the SAC solder paste series alloy. As a result, it perfectly solves the selection problem of lead-free solder paste for secondary reflow of components and circuit boards. It is also a perfect solution for circuit boards that require secondary reflow.

Figure 4. The reflow profile of Fitech’s FL200 low-temperature high-strength solder

Summary

Fitech's secondary reflow solder paste solution is based on high-strength low-temperature lead-free solder paste.

1) The secondary reflow can be achieved at a lower temperature;

2) No harmful metals such as antimony and lead are used;

3) The soldering strength of FL200 product is almost the same as that of SAC solder paste;

4) Energy-saving and environmental protection.

Innovation and practicality are the characteristics of Fitech's secondary reflow solder solution.

-End-

Back to list

Back to list