What are the Characteristics of Water-Soluble Solder Paste_Solder Paste Cleaning

What are the Characteristics of Water-Soluble Solder Paste_Solder Paste Cleaning

The traditional solder flux is formulated with rosin or epoxy resin as the base material, mixing with an active agent, thixotropic agent, solvent, and other substances. At present, two major factions of no-clean solder paste and water-soluble solder paste have been derived based on flux compositions. No-clean solder paste, as the name suggests, produces a tiny amount of residue after soldering and is unnecessary to clean. Although no-clean solder paste has less activity, it can still meet most consumer electronics soldering needs. Currently, no-clean solder paste is adopted by the majority of companies because of its good stability and simple use process. However, some solders require higher flux activity, and the residue level is unacceptable, which needs to be removed by using cleaning agents.

Features of Water-Soluble Solder Paste

The water-soluble solder paste is still made by mixing alloy solder powder and flux but using water-soluble flux components. Water-soluble solder pastes are formulated with inorganic or organic fluxes. The inorganic formulation adopts inorganic acids or inorganic salts as matrix substances. Inorganic acids include hydrochloric acid, hydrofluoric acid, etc. For inorganic salts, zinc chloride and ammonium chloride are used. The residue generated after soldering is highly corrosive and needs to be removed with deionized water in time. Organic formulations use lactic acid and citric acid as matrix substances. Similar to inorganic formulations, organic formulations are acidic but less corrosive.

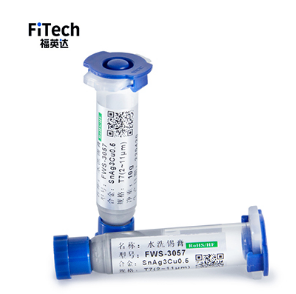

Figure 1. Water-soluble solder paste.

Solder Paste Cleaning Process

There are many cleaning methods, such as water-based, alcohol-based, ether-based cleaning, etc. The water-soluble solder paste mentioned in this article is a solder paste that uses deionized water for residue cleaning. The cleaning agents used can also be divided into semi-water-based and water-based cleaning. Currently, water-based cleaning is widely used. The circuit board is cleaned by soaking, spraying, ultrasonic, and other methods and then rinsed with deionized water. Deionized water temperature is generally controlled between 25-60 °C. Finally, the PCBs are dry with hot air at 80°C or dry naturally. It should be noted that natural drying takes a long time, which will reduce production efficiency. Manufacturers need to make research and judgments based on actual needs.

Fitech can produce high-quality water-soluble solder paste with high soldering reliability. The solder joints are bright and free from cleaning. Welcome to contact us for more information.

Back to list

Back to list