What are the Requirements for Lead-Free Solder Pastes from an Industrial Application Point of View?

At present, there is no universally recognized set of specifications for lead-free solder pastes. From the perspective of industrial application, the following basic technologies and application requirements of lead-free solder pastes are summarized:

(1) Price: Many manufacturers want the lead-free solder pastes to be cheaper than Sn37Pb, but the reality is that cost of lead-free substitutes is 25% higher than Sn37Pb. When choosing tungsten electrodes and wires, the metal cost is the primary factor. When making solder paste, metal price is less sensitive because the process cost accounts for a relatively large proportion of the overall production cost,

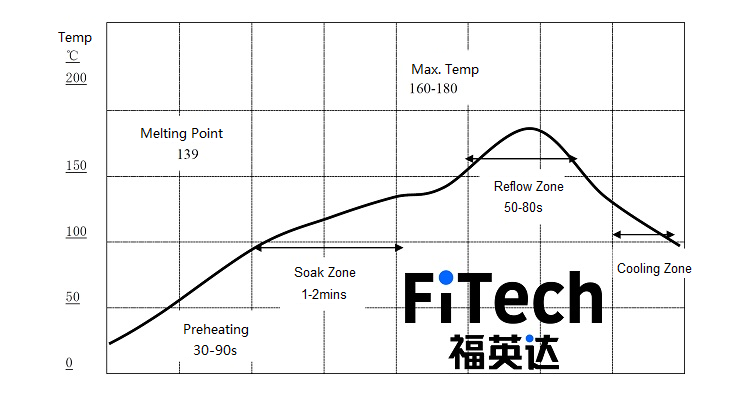

(2) Melting point: According to the manufacturer's requirements, the solidus temperature of the ordinary low-temperature lead-free solder paste is 139°C to meet the low-temperature soldering requirements of electronic equipment. The maximum liquidus temperature of low-temperature lead-free solder paste depends on the specific application.

The liquidus temperature of high-temperature lead-free solder pastes such as gold-tin solder paste is above 280°C.

Generally, the reflow temperature should be selected according to the lead-free solder paste used. It is ideal to avoid higher reflow soldering temperatures, which can minimize the damage of components, reduce the demand for special components, and can minimize the discoloration and warpage of the PCBs, and avoid excessive oxidation of the pads and wires.

(3) High conductivity: This is the basic requirement for lead-free solder paste in electronic connections.

(4) Good thermal conductivity: In order to dissipate heat energy, the solder joints formed by lead-free solder paste must have rapid heat transfer capability.

(5) Solid-liquid coexistence temperature range: The non-eutectic alloy solidifies within a certain temperature range between the liquidus temperature and the solidus temperature. Many metallurgical experts suggest that this temperature range should be controlled within 10°C to form excellent solder joints and reduce defects. If the solidus temperature range of lead-free solder alloy is large, cracking of solder joints is easy to occur, which results in premature failure of equipment.

(6) Low toxicity: The alloy compositions of lead-free solder pastes must be non-toxic, which requires lead-free solder alloys to exclude cadmium, thallium, and mercury. Some products require that by-products extracted from toxic substances cannot be used, such as bismuth, since they mainly come from by-products from lead refining.

7) Excellent wettability: In the case of existing equipment and no-clean flux, lead-free solder paste should have sufficient wettability. For SMT reflow soldering, lead-free solder paste alloys are more suitable for reflow soldering in the air due to the high cost of inert processing in the reflow oven. However, in the semiconductor industry, the reliability of lead-free soldering is getting higher and higher, and inert gas protection is essential during the reflow process of lead-free solder pastes.

(8) Good physical properties (strength, tensile, fatigue, etc.): The lead-free solder paste alloy must provide sufficient mechanical strength and reliability. No raised fillet welds (especially for alloys with a large solid-liquid temperature range) are created on through-hole devices.

(9) Repeatability of production/consistency of melting point: The electronic assembly process is a large-scale manufacturing process that needs to maintain high repeatability and consistency. In the mass production process, the alloy composition of some lead-free solder pastes cannot be remanufactured, or their melting point changes significantly during mass production due to composition changes, so they cannot be considered.

(10) Solder joint appearance: The appearance of lead-free solder joints should be similar to that of tin-lead solder. Although appearance is not a technical requirement, it is the actual demand for lead-free solder pastes to accept and implement alternatives.

(11) Supply capacity: It is necessary to consider whether there are sufficient supply sources for the materials used in lead-free solder pastes. From a technical point of view, indium is a relatively special material, but considering the ability of global supply, indium will be completely excluded.

(12) Compatibility with lead: Since lead may still be used for some component junction boxes or PCB pads in the short term, lead-free solder paste should be compatible with lead. The melting point of some lead-containing alloys is low, which significantly reduces the soldering strength.

-End-

*Disclaimer: Except for "reprinted" articles, the copyright of the original content published on this site belongs to Shenzhen Fitech. Without consent and authorization, it may not be reproduced, reproduced, quoted, changed, or published. This article is originally created by the author, and the content of the article is the author's personal opinion. "Reprint" is only to convey a different point of view and does not mean approval or support for the point of view. If there is any infringement, please contact us, and we will delete it!

Back to list

Back to list