The "White Paper on Ultra-Fine-pitch LED Display Research" Co-Edited by Fitech was Released

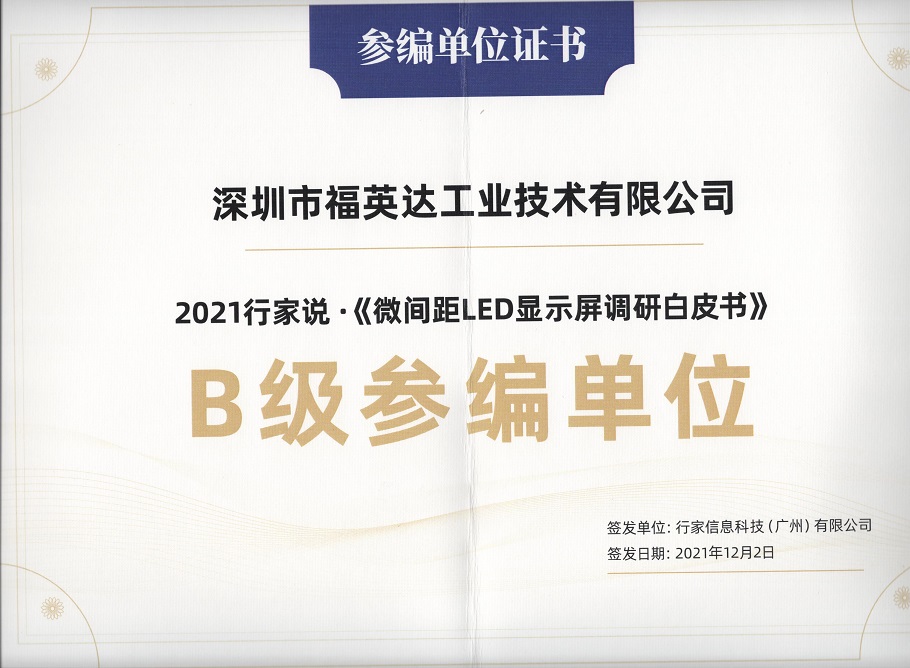

Ultra-fine-pitch LED displays, including micro LED, mini LED, and mini LED backlight displays, have become a new hot spot in the industry since 2018. Organized by the expert, Fitech participated in the compilation of the white paper on the package solder/solder paste for ultra-fine-pitch LED display. On December 2, 2021, Fitech was invited to attend the Mini LED Backlight and Ultra-Fine-Pitch Display Application Conference and was awarded the certificate of the participating unit.

Different from LCD and OLED, micro LED display has the advantages of high brightness, high reliability, high contrast, energy saving, and environmental protection. Mini LED and mini LED backlights have become hot spots in the past two years.

As one of the packaging materials supporting the continuous development of micro LED and mini LED and the shrinking size, packaging solder (solder paste, epoxy solder paste, and other materials) is an important factor in the development of micro LED and mini LED display technology. In order to reliably solder micro LED and mini LED chips, the solder powder particles must be small enough. Type 6 (5-15um) ultra-fine solder paste can be used for chips with a size larger than 240umx130um. There are only a few solder paste companies able to produce T7 (2-11um) SAC305 ultra-fine solder paste, which is suitable for chips with sizes larger than 200umx100um. Fitech’s T8 (2-8um) ultra-fine solder paste (SAC305, SnBiAg, and other alloys) can meet the soldering requirements of a minimum 130umx75um chip and meet different temperature requirements.

Fitech has been established for 20 years and is a semiconductor packaging solder solution provider specializing in the research, development, production, and sales of ultra-fine lead-free solder paste and epoxy solder paste. Fitech's ultra-fine solder paste and epoxy solder paste cab fully meet the soldering requirements for micro LED and mini LED displays. For ultra-fine-pitch soldering, there are other solutions such as T9 (1-5um) and T10 (1-3um) solder paste, epoxy solder paste, anisotropic conductive adhesive, and others.

-End-

*Disclaimer: Except for "reprinted" articles, the copyright of the original content published on this site belongs to Shenzhen Fitech. Without consent and authorization, it may not be reproduced, reproduced, quoted, changed, or published. This article is originally created by the author, and the content of the article is the author's personal opinion. "Reprint" is only to convey a different point of view and does not mean approval or support for the point of view. If there is any infringement, please contact us, and we will delete it!

Back to list

Back to list