Characteristics and Types of Water-Soluble Flux-Shenzhen Fitech

Characteristics and Types of Water-Soluble Flux

Water-soluble flux is a kind of flux widely used in the electronic soldering process, it can improve the wettability of the solder, prevent oxidation, and clean the residue with water after soldering.

The biggest feature of water-soluble flux is that the flux component is highly soluble and active in water with good fluxing performance, and the residue after soldering is easily soluble in water, so water can be directly used as the cleaning solvent. No consumption of ODS and VOC, reducing environmental pollution and safety risks.

According to the different active substances used, water-soluble flux can be divided into:

Zinc chloride, tin chloride and ammonium chloride are often used as active substances, which have good soldering flux, high temperature resistance and easy cleaning. However, the corrosiveness of its post-soldering residue, so it is prohibited to use in the assembly of electronic products welding.

Organic Water-Soluble Flux

Apply to PCB assembly welding, dip welding, electronic components pin tin. This type of flux to rosin-based flux for the mainstream. Organic water-soluble flux and inorganic system, corrosive than the inorganic system is weak, but stronger than the rosin system, hygroscopicity is also large.

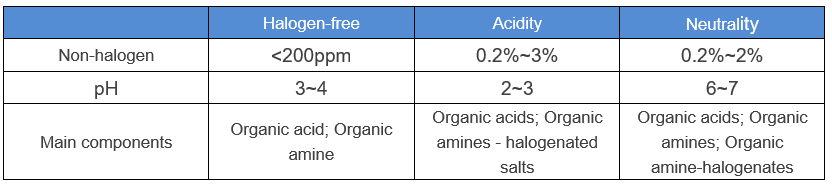

Table 1. Organic water-soluble flux classification

Non-halogenated water-soluble flux: mainly organic acids and organic amines. Due to the absence of halogens, the residue is almost non-corrosive, but due to the use of a large number of organic active agents, so more residual ions.

Acidic water-soluble flux: contains halide 0.2% ~ 3%, pH value of 2 ~ 3. Because of the halide, so the organic acid content is less, the residual ions are also less.

Neutral water-soluble flux: also contains halide. pH value of 6 ~ 7, so there is no corrosive effect on the PCB and components.

The use of water cleaning process need to consider the following factors

(a)In order to ensure the quality of cleaning, the use of pure water quality must meet certain requirements;

(b)Use the appropriate temperature, pressure and time for cleaning, otherwise it will lead to incomplete removal of residues or damage to components;

(c)Water-soluble flux should be stored in a dry, cool environment to avoid moisture absorption and deterioration, to ensure its performance stability.

In short, the water-soluble flux superior fluxing performance, easy to clean features and friendly to the environment, making it a reliable choice for electronic soldering, promoting the progress and development of electronic manufacturing technology. When using, should follow the corresponding operating procedures to ensure welding quality and work safety.、

Shenzhen Fitech Co., Ltd. produces water-soluble flux FWF-5100, which has high soldering reliability, easy to clean and no residue after cleaning, and good wetting performance. Welcome to contact us for more information.

Back to list

Back to list