The Effect of Operating Temperature on Au-Sn Solder Joints_Shenzhen Fitech

The Effect of Operating Temperature on Au-Sn Solder Joints_Shenzhen Fitech

In recent decades, the demand for reliable high-temperature electronic equipment has grown rapidly, mainly concentrated in applications such as aerospace, power electronics, and military equipment. The use of these high-temperature electronic devices has extremely high requirements for the strength and stability of solder joints. Silicon carbide (SiC) is a material that adapts to high temperatures and is generally considered the preferred semiconductor for high-temperature applications. Au-Sn solid-liquid interdiffusion (SLID) is a technology that can be used for high-temperature bonding. This technology often uses eutectic gold tin solder paste, which can bond chips to substrates at temperatures of 280℃ or higher and has high solder joint reliability. However, the use temperature of electronic devices usually has different effects on solder joints, so the strength of gold tin solder joints also needs further observation.

1. Shear strength test

Tollefsen et al. conducted shear tests on four Au-Sn SLID sample groups at room temperature, 100°C, 200°C, and 300°C, each containing six samples. The shear strength test was to apply 110μm test height above the substrate, and the test speed was 10μm/s.

2. Test results

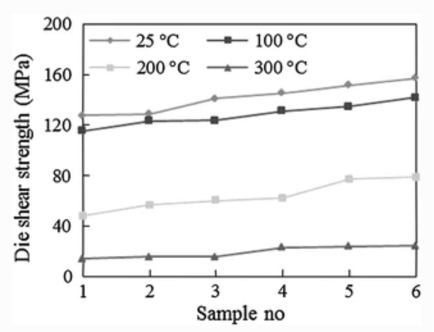

Figure 1 shows the relationship between chip shear strength and usage temperature. From the graph, it can be seen that there is a negative correlation between shear strength and usage temperature. When the temperature is below 100℃, the shear strength of the chip only decreases slightly with increasing temperature, from about 140MPa to about 130MPa. The reason is that the increased thermal energy reduces the chemical binding energy and causes thermal softening of solder joints. However, when the operating temperature rises from 100°C to 200°C, the chip shear strength significantly decreases to around 60 MPa. At 300°C, the shear strength continued to decrease, dropping to around 20MPa, which is lower than 15% of the chip shear strength at room temperature.

Figure 1. Chip shear strength of Au-Sn SLID samples at different usage temperatures.

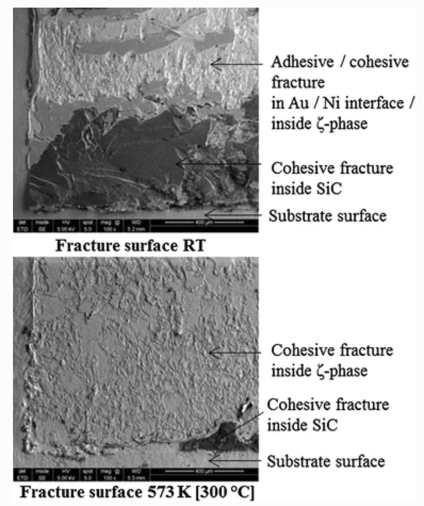

The following figure shows the fracture surface of Au-Sn SLID samples subjected to shear testing at room temperature and 300°C. It can be observed that as the temperature increases, the fracture mode changes from adhesive Au/Ni and cohesive ζ phase/SiC fracture to dominated cohesive ζ phase fracture. This indicates that the significant decrease in shear strength is due to the weakening of the Au-Sn SLID bond.

Figure 2. The fracture surface of Au-Sn SLID samples at room temperature and 300℃.

3. Fitech's solder paste

Shenzhen Fitech has professional experience in the research and production of high-temperature solder paste, which can provide customers with high-quality gold-tin solder paste for high-soldering temperature needs. Fitech’s gold-tin solder paste has the advantages of stable viscosity, low residue, and high solder joint strength. We welcome customers to cooperate with us in depth.

4. Reference

Tollefsen, T.A., Løvvik, O.M., Aasmundtveit, K. et al. (2013). Effect of Temperature on the Die Shear Strength of a Au-Sn SLID Bond. Metall Mater Trans A 44, 2914–2916.

Back to list

Back to list