The mechanical strength of high-temperature gold-germanium solder_Shenzhen Fitech

The mechanical strength of high-temperature gold-germanium solder_Shenzhen Fitech

When talking about lead-free solder, people often think of tin-bismuth solder, tin-silver-copper solder, and tin-antimony solder. These solders have a wide range of applications, covering different soldering temperatures, but are limited to melting temperatures below 300°C. Due to the rise of power devices and aerospace materials, which often require soldering temperatures above 300°C, some scholars have proposed gold-germanium eutectic solder (Au88Ge12). The melting point of gold-germanium eutectic solder is extremely high, reaching 361°C, and this solder has good mechanical, thermal, and electrical properties.

Gold-germanium eutectic solder and Cu substrate can be soldered at around 400°C. During the soldering process, the gold-germanium alloy will react with the Cu substrate at the interface and form a hexagonal close-packed solid solution (HCP). Mechanical strength is one of the concerns about high-temperature devices. The growth of HCP will have a direct impact on the shear strength of the solder joint, so more research is needed.

Experimental design

Wang and Peng (2023) used gold-germanium eutectic solder sheets to solder with Cu substrates. The soldering experiments were conducted in a 400°C furnace (under an H2 atmosphere) with continuous heating for 5mins, 20mins, and 60mins. RGM4100 universal mechanical machine was used for testing shear force.

Experimental results

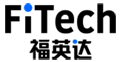

Figure 1 shows the solder joints after welding at 400°C for 5mins, 20mins and 60mins. Taking soldering for 5mins as an example, in the BSE image, the bright matrix is the Au phase. The Ge and Cu contents in the Au phase are approximately 7at.% and 30at.%, respectively. The gray region close to the Cu substrate is the interface reaction product HCP solid solution. Through EDX, it can be found that HCP is Cu−24Au−12Ge. When welded for 5 minutes, the thickness of HCP is 1.8μm. Through further inspection, it was found that when the soldering time increased from 5mins to 20mins, the thickness of the HCP layer increased from 1.8μm to 5.6μm. The average grain size of HCP increased to 2.9μm. In addition, the Ge content dropped from ~18.6at.% to ~8.1at.%. The average grain size remains at (5.7±3.1)μm. After 60 minutes of soldering, almost all the solder is consumed and HCP is generated, leaving only a very small amount of Ge.

Figure 1. Backscattering patterns of gold-germanium solder joints with different soldering times. (a) 5mins; (b) 20mins; (c) 60mins.

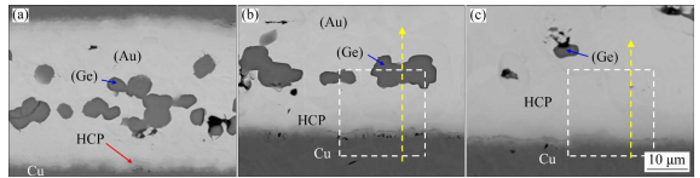

In order to understand the effect of the HCP layer on the shear strength of Au−Ge solder joints, Wang and Peng conducted shear fracture tests on the solder joints at room temperature at a tensile rate of 1 mm/min. It can be seen from Figure 2 that when soldering for 5 minutes, the solder joint fracture mainly occurs along the Ge grains in the solder matrix. Due to the brittle nature of Ge, cleavage planes can be observed in the solder joints, showing a brittle fracture mode. When the soldering time increases to 20 minutes, the Ge content decreases significantly from 18.6 at.% to 8.1 at.%. Therefore, the solder joint fracture mode begins to change to ductile fracture. When the soldering time is 60 minutes, the fracture mode of the solder joint is a ductile fracture.

Figure 2. Fracture morphology of Au−Ge solder joints with different soldering times. (a) 5mins; (b) 20mins; (c) 60mins.

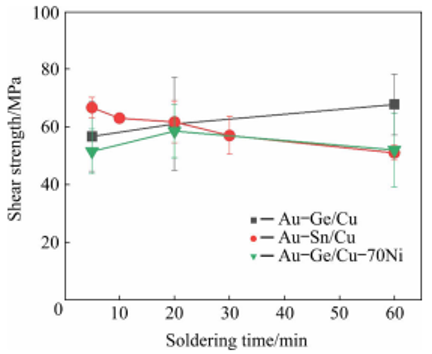

The shear strength of gold-germanium solder joints is related to the soldering time. When the soldering time is 5 minutes, the shear strength of the solder joint is 57MPa. As the soldering time increases, the shear strength of the solder joint also increases. When the soldering time is 60 minutes, the shear strength of the solder joint reaches a maximum value of 68MPa. In addition, when the soldering time exceeds 20mins, the shear strength of gold-germanium solder joints is obviously better than that of gold-tin solder joints because increased soldering time causes the gold-tin solder joints to form brittle Au6.6Cu9.6Sn3.8 phase, which reduces the strength of the solder joints.

Figure 3. Shear strength of different solders soldered with substrates.

Reference

Wang, M. & Peng, J. (2023). Formation of ductile close-packed hexagonal solid solution on improving shear strength of Au–Ge/Cu soldering joint. Transactions of Nonferrous Metals Society of China, vol.33(8), pp.2449-2460.

Back to list

Back to list