How Low-Temperature Epoxy Solder Joint Is Affected by Residues-Shenzhen Fitech

How Low-Temperature Epoxy Solder Joint Is Affected by Residues-Shenzhen Fitech

Since the ban on the use of lead in electronics, lead-free solder alloys have gained momentum as alternatives to tin-lead solders. Eutectic tin-bismuth alloy has a very low melting point, good wettability, and low thermal expansion coefficient. Therefore, it can be used for component packaging and multiple reflow processes with poor heat resistance. Epoxy solder paste prepared by epoxy resin and eutectic tin-bismuth (Sn42Bi58) has great application potential. Compared with traditional rosin solder paste, the use of epoxy resin brings a stronger physical connection between the chip and the PCB board without an underfill process, improving the mechanical properties of the solder joints. Although epoxy resin curing is an important factor in determining the strength of solder joints, the effect of the reflow process cannot be ignored.

Experimental design

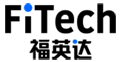

Regarding the impact of the reflow process on epoxy eutectic tin-bismuth solder paste, Lee et al. carried out a series of work. Lee et al. soldered epoxy solder paste to ENIG pads. Reflow was performed using a four-zone IR reflow machine under air conditions, with different peak temperatures (160°C, 170°C, 180°C, 190°C) and heating rates (1°C/s, 2°C/ s, 3°C/s).

Figure 1. Experimental reflow profile.

Results

Residue analysis

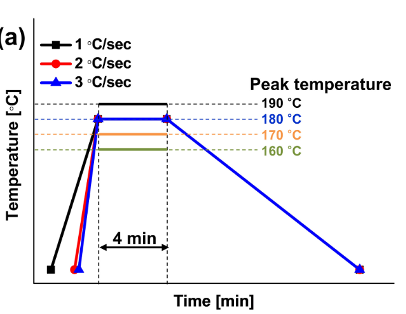

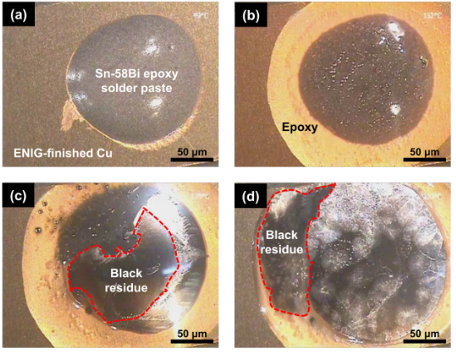

Figure 2 shows the state changes of epoxy Sn42B58i solder paste during the reflow process. No significant changes in appearance were observed when the temperature was increased to 140°C. In the temperature range of 140°C to 155°C, the solvents and volatile components in the epoxy solder paste evaporate rapidly, and the epoxy simultaneously oozes out and covers the solder joint. When the temperature exceeds 160°C, black residues form on the surface of the solder joint and solidify after reaching the peak reflow temperature. Furthermore, it was found that both low peak temperatures and high heating rates resulted in an increase in the number of black residues. When the peak temperature increases from 160°C to 190°C, the area ratio of black residues decreases from 50.3% to 18.0%. Through analysis, it was found that the composition of the black residues contained epoxy residue, Sn, Bi, and carboxylates such as Bi(RCOO)3 and Sn(RCOO)2. The formation of these carboxylates is attributed to the reaction of organic acids with oxides.

Figure 2. Epoxy Sn42B58i solder joints at different temperatures. (a)140°C; (b)140-155°C; (c)160°C.

Figure 3. Amount of black residues on solder joints at different temperatures.

Solder joint strength

As the peak temperature increases from 160°C to 190°C, the shear strength of the solder joint increases by 31.3%. As the reflow temperature increases, the fracture mode of the solder alloy exhibits greater ductility. In addition, after breaking the solder joint, black residues can be found inside the solder joint. At the lower temperature of 160°C, the number of black residues on the solder joints is the largest and the diameter reaches 20μm. When the peak temperature rises to 180°C, the diameter of the residue decreases significantly. Almost no residue is observed at 190°C, indicating that residue forms inside and outside the solder joints at lower peak temperatures, which reduces the shear strength of solder joints.

Figure 4. Epoxy Sn42Bi58 solder joint strength and fracture surface.

Reference

Lee, C.J., Bang, J.O. & Jung, S.B. Effect of black residue on the mechanical properties of Sn-58Bi epoxy solder joints. Microelectronic Engineering, vol. 216.

Back to list

Back to list