A Jetting Solder Paste for Mini-LED Backlight COB Panel

LED-backlit display is the most mature industrial LED application in display panels, and the commercialization process has been completed. Currently, the packaging process adopted by major domestic manufacturers follows the steps of die bonding, reflow soldering, cleaning, and backlight COB complement. Because the LED chips on the direct-display COB board have relatively large pitches, the amount of chips is far less than that of the direct-display mini-LED panel. Therefore, the actual amount of solder paste used is small for printing. Since the solder paste used on the LED COB pads is generally made of ultra-fine powder (1-15μm), the price is relatively high. The processing time is shorter than that of ordinary SMT solder paste. Due to the change of physical activity such as viscosity and thixotropic properties during the printing process, it is easy to affect the consistency and stability of the printed solder joints. The printing solder paste used on the COB should be replaced in time, leading to a significant waste of solder paste. The cost of the manufacturing process is increased.

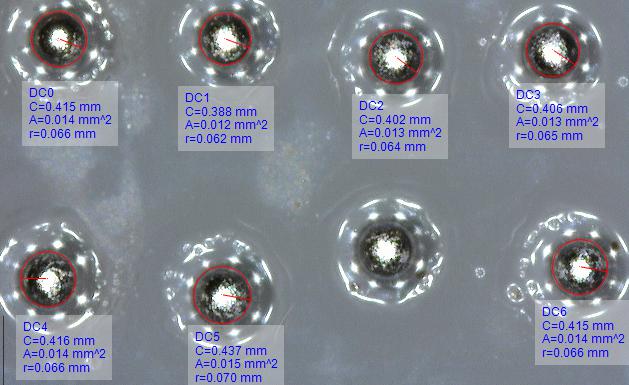

Fitech has developed jetting and dispensing ultra-fine solder paste for LED backlight COB boards. Liquid-phase forming ultra-fine solder powder with 100% sphericity, smooth spherical surface, and narrow particle size distribution is mixed with a high-efficiency flux carrier to prepare these products. It is available to use jet printing and dispensing to accurately form uniform and consistent 50-200μm micro-solder points on the LED backlight COB board, which avoids the waste of expensive ultra-fine solder paste. The dispensing speed can reach 18kuph, which meets the requirements of the process progress.

-End-

Back to list

Back to list