What are the Particle Sizes of Solder Paste Alloys

What are the Particle Sizes of Solder Paste Alloys

Social consumer groups have increasingly higher performance requirements for electronic products. In order to meet the needs of consumers, semiconductor manufacturers must speed up their development. With the rapid development of electronic technology, the size of the chip is getting smaller, and the precision is getting higher. As a result, the pad size and pitch of the PCBs are reduced. Therefore, in addition to meeting the packaging requirements of conventional chip sizes, solder paste must also be suitable for more miniaturized packaging scenarios.

For solder alloy size selection, reference component size is required. There are currently T2-T10 types of solder pastes. Each type corresponds to different powder size. It is required that 80% of the alloy particle size distribution is within a specific size interval. For example, in T2 solder paste, 80% of the alloy particle should have a diameter distributed in the range of 45-75μm. The table below shows alloy categories and corresponding sizes. Due to the reduction in chip size and the increase in packaging density, ultra-fine solder paste has emerged in the packaging material industry. T6-T10 solder pastes can be regarded as ultra-fine solder pastes. Due to the small size of ultra-fine solder paste particles, it can be used for ultra-fine-pitch packaging.

Table 1. Solder alloy particle sizes.

Type | Alloy Size (μm) |

T2 | 45-75 |

T3 | 25-45 |

T4 | 20-38 |

T5 | 15-25 |

T6 | 5-15 |

T7 | 2-11 |

T8 | 2-8 |

T9 | 2-5 |

T10 | 1-3 |

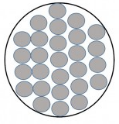

The printing process is a very common packaging process. The solder paste placed on the stencil is filled into the stencil apertures and deposited onto the pads using a squeegee. The stencil aperture size needs to match the pad size. According to the five-ball rule, the length of the narrow side of the apertures should accommodate at least five alloy particles. Therefore, if the aperture size is 80μm, T6 solder paste should be selected (5x15=75<80). For circular apertures, the aperture diameter needs to be eight times the size of the solder particle.

Figure 1. Stencil aperture shapes and the number of solder particles.

Due to the current process limitations, the minimum size that can be achieved by printing stencil aperture is 50 μm. Hence, there is still great potential for T8 solder paste and above. However, T2-T8 solders are still the mainstream products because T9 and T10 solder pastes are limited by production technology that cannot achieve large-scale applications. It is worth noting that the small solder size may increase the risk of solder paste oxidation, and the requirements for flux activity are high. Hence, the appropriate solder paste should be selected according to the chip size and production cost.

Fitech is committed to the production of solder paste products for semiconductor packaging and is currently the only manufacturer capable of producing T2-T10 solder pastes. Fitech’s solder products have high sphericity, excellent wettability, and narrow particle size distribution, which make them suitable for various packaging scenarios. Welcome to inquire.

Back to list

Back to list