The Basic Knowledge of Lead-Free Solder Paste (1)_Shenzhen Fitech

The Basic Knowledge of Lead-Free Solder Paste (1)_Shenzhen Fitech

Lead-free solder paste has been proven to be an environmentally friendly soldering material that can basically replace leaded solder paste. Solder paste is deposited on the pads by printing or dispensing. The solder does not melt the base metal during the soldering process. Small amounts of solder paste will melt and combine with the base metal to form intermetallic compounds (IMCs). There are many types of IMCs, depending on the metal composition of the solder paste and base metal. It is clear that semiconductor soldering is a metallurgical connection process in which the solder alloy is consumed in a molten state at high temperatures and interconnected with the pads.

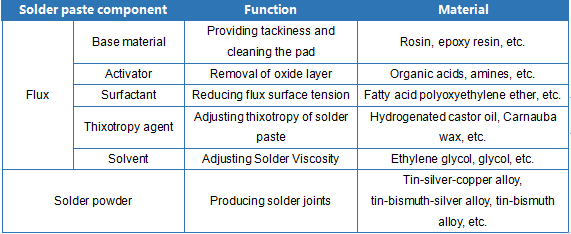

Lead-free solder paste composition and important properties

Lead-free solder paste is a gray paste-like material whose most important components are alloy solder powder, rosin/epoxy flux, and a small number of additives. Lead-free solder paste is a shear-thinning substance that becomes less viscous under the shearing action of printing so that it can pass through the stencil. The solvent composition in the flux plays a key role in adjusting the viscosity. Tackiness is also one of the factors affecting soldering, which can play a role in fixing the chip. In addition, in order to achieve metallurgical connections, the solder paste needs to have outstanding wettability, which is related to the ability of the solder paste to spread and flow on the pads. The activator and surfactant in the flux can remove the oxide layer on the surface of the pads and reduce the surface tension, respectively. Therefore, the solderability of the solder pastes can be enhanced.

Table 1. The compositions of the solder pastes and functions.

Lead-free solder paste alloy compositions and melting points

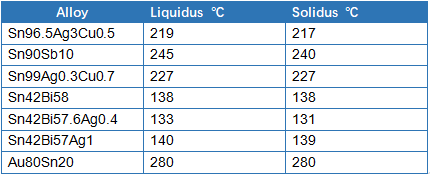

The melting point of a lead-free solder paste depends on its alloy composition. The tin-bismuth/tin-bismuth-silver solder pastes constitute a low-temperature solder system. Tin-silver-copper solder pastes are the most commonly used solder for medium-temperature soldering. High-temperature solder pastes are used in a few scenarios, mainly in power devices, aviation, aerospace, and other fields. The representative lead-free solder pastes include gold-tin solder paste and tin-antimony solder paste. Manufacturers can choose the corresponding lead-free solder pastes according to the process temperature requirements. The table below shows the melting points of some popular solder pastes. More solder paste property information can be found on the official website of Fitech.

Table 2. Lead-free alloy powders and melting points.

Fitech is a world-leading provider of microelectronics and semiconductor packaging materials solutions. Fitech’s solder paste, epoxy solder paste, and other solder products have an outstanding wetting effect, narrow powder particle size distribution, and high post-soldering reliability. Welcome to the official website for more information.

Back to list

Back to list