The Basic Knowledge of Lead-Free Solder Paste (2)_Shenzhen Fitech

The Basic Knowledge of Lead-Free Solder Paste (2)_Shenzhen Fitech

Continued from "The Basic Knowledge of Lead-Free Solder Paste (1)"

When manufacturers choose a suitable lead-free solder paste, the process temperature should be confirmed prior. The melting point of the solder paste needs to be within the temperature range of the soldering process. The suitable lead-free solder paste can be chosen regarding the melting point. After selecting the solder paste with an appropriate melting point, the solder paste can be applied to the pads according to the supplier's instructions in the process of printing, dispensing, and jetting.

Commonly-Used Alloys for Lead-Free Solder Pastes

Eutectic tin-bismuth alloy can be used to produce the low-temperature lead-free solder paste with the alloy composition of Sn42Bi58. In the eutectic state, the melting point of the alloy can reach a minimum value. The melting point of Sn42Bi58 is 138 °C. Due to the low melting point, the resulting thermal stress is small. However, since bismuth is a brittle metal, the solder joints are prone to brittle fracture. Another common low-temperature alloy combination is Sn42Bi57.6Ag0.4. The addition of silver can enhance the brittleness of the solder joint and the electrical conductivity.

Medium-temperature solder pastes

The most common medium-temperature solder paste is Sn96.5Ag3Cu0.5. This is based on Sn-Ag alloys with a small amount of Cu added. The addition of copper has a positive effect on lowering the melting point of the alloy. The melting point of Sn96.5Ag3Cu0.5 is 217℃. Due to the moderate melting temperature, Sn96.5Ag3Cu0.5 is usually used for the first reflow of multiple reflow soldering.

High-temperature solder pastes

Common high-temperature lead-free solder pastes include tin-antimony and gold-tin alloys. Sn90Sb10 has a melting point of 245°C, which is suitable for high-temperature soldering. The other is Ag80Sn20 gold-tin solder paste. The melting point of the eutectic gold-tin solder paste is 280 ℃. Ag80Sn20 solder paste can be applied without the aid of flux, and the solder joints are reliable and free of residues.

Solder Paste Printing Process

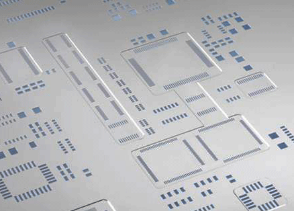

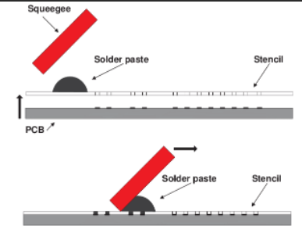

Printing is an important means of applying solder paste on pads. The most common method is stencil printing, which requires stencils with apertures corresponding to the pads. It is important to rewarm the lead-free solder paste to room temperature and stir it for 2-5 minutes before placing it on the stencil. The viscosity of the solder paste decreases sharply after being sheared by the squeegee, allowing it to pass through the apertures (Figure 2). The viscosity returns to normal levels after the shear force is removed. As a result, the solder paste deposits on the pads. It can be known that viscosity is an important factor in printing quality. Excessive high viscosity will make it difficult for the solder paste to enter the apertures, while low viscosity will easily cause slumping. Hence, the flux formulation needs special attention. Due to the long printing duration and poor flexibility, stencil printing is only suitable for mass production.

Figure 1. A stencil aperture pattern.

Figure 2. Printing Process.

Solder Paste Dispensing Process

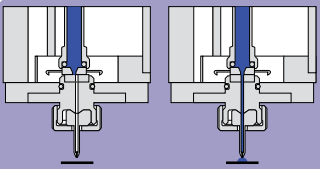

Dispensing technology is also used to make solder joints. Dispensing solder paste is stored in the syringe, which is released onto the pads under the dispenser pressure. The dispensing process is contactless and does not require stencils. Dispensing is to release the solder paste from the syringe through the action of pressure, which requires the solder paste to have excellent fluidity. Thus, the viscosity of the dispensing solder paste should be relatively smaller than that of the printing solder paste. Solder formulation, pressure, needle diameter, and dispense pitch are the crucial variables that affect solder paste dot size. Therefore, the operating parameters of the solder dispenser need to be adjusted according to the actual solder point requirements. Moreover, the underfill adhesive can be applied to one side of the solder joint by adopting dispensing process. The gap between solder joints can be filled by capillary action to protect the solder joints.

Figure 3. Structure of a solder dispenser.

Fitech is a world-leading provider of microelectronics and semiconductor packaging materials solutions. Fitech’s solder paste, epoxy solder paste, and other solder products have an outstanding wetting effect, narrow powder particle size distribution, and high post-soldering reliability. Welcome to the official website for more information.

Back to list

Back to list