The Basic Knowledge of Lead-Free Solder Paste (3)_Shenzhen Fitech

The Basic Knowledge of Lead-Free Solder Paste (3)_Shenzhen Fitech

Continued from "The Basic Knowledge of Lead-Free Solder Paste (2)"

The printing and dispensing processes of lead-free solder paste were described in the previous article. These methods enable the solder paste to be applied to the pads. There is also a typical process called solder paste jetting, which can also apply solder paste on the pads. To adapt to the jetting process, jetting lead-free solder paste was derived. After the solder paste dots are made, the components are mounted on the solder paste dots. When all assembly work is completed, the PCBs will enter a reflow oven for reflow soldering or finish soldering by hot pressing.

Solder Paste Jetting Process

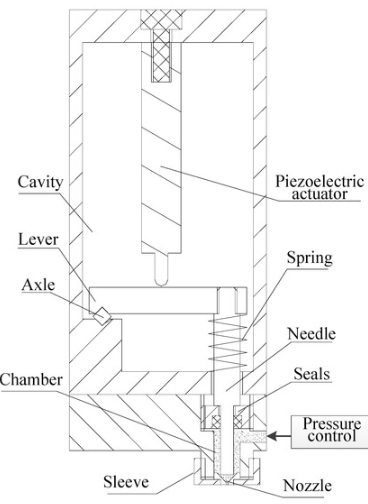

In order to improve the shortcomings and instability of solder paste dispensing and printing in the SMT production process, a non-contact solder paste injection system based on the nozzle-needle principle was born. The principle of the solder jetting printer is similar to that of an inkjet printer, which sprays lead-free solder paste onto the substrates by applying a momentary high pressure. The jetting process does not require changing the Z-axis motion, which significantly increases the speed of solder paste deposition on a variety of surfaces compared to contact dispensing. Jetting also makes it easier to deposit solder paste onto uneven substrate surfaces. The lead-free solder pastes used in the jetting process are mostly Sn42Bi58, Sn42Bi57.6Ag0.4, and Sn96.5Ag3Cu0.5. Due to the advantages of short jetting time, high operational flexibility, and low cost, the jetting process has been widely used.

Figure 1. The mechanical structure of a jetting machine.

Lead-Free Solder Paste Reflow Soldering

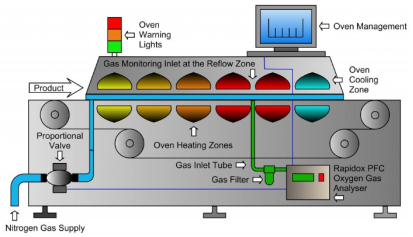

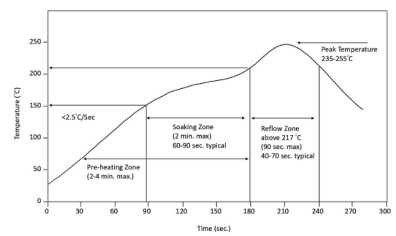

After the lead-free solder paste is printed on the substrates and the components are mounted, the PCB is sent to the reflow oven. Under the action of furnace temperature and nitrogen protection, the solder paste gradually melts. After cooling, the solder paste will melt and solidify into solder joints. Reflow soldering includes preheating, soak, reflow, and cooling zones. The reflow profile contains the temperature change rate, peak temperature, and duration for each zone. The heating rate of the preheating zone is between 2-3 °C. In this area, the PCBs are preheated, the flux begins to wet the pads and remove the oxide layer, and the solvent starts to volatilize. In the soak zone, the flux continues wetting the pads, and the solvent is further volatilized. The solder paste is heated to the peak reflow temperature in the reflow zone to completely melt and form intermetallic compounds with the pads. The molten solder solidifies into solder joints after cooling, and the grains are refined, resulting in better mechanical strength. Importantly, the reflow profiles will vary depending on the soldering processes.

Figure 2. A reflow oven.

Figure 3. A reflow profile.

Pulsed Heat Hot Press Soldering

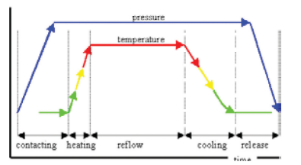

Hot press soldering requires the use of a hot press machine, which is often used for flexible circuit soldering. Hot press soldering is partial heating, while reflow soldering is entire PCB heating. A thermocouple is welded in front of the hot electrode inside the hot press machine, which generates Joule heat under the impacts of current and electrical resistance. Heating starts when the hot indenter contacts and presses the soldering surface. The lead-free solder paste melts and wets the pad with the assistance of the flux, which solidifies to form solder joints after cooling. The pressure of the hot press needs to be precisely tuned to ensure good heat transfer. In addition, the lead-free solder paste is instantly heated when hot pressing. Thus, the solder paste needs to maintain an outstanding anti-spatter capability.

Figure 4. A reflow profile for pulsed heat hot press soldering.

Fitech is a world-leading provider of microelectronics and semiconductor packaging materials solutions. Fitech’s solder paste, epoxy solder paste, and other solder products have outstanding wetting effect, narrow powder particle size distribution, and high post-soldering reliability. Welcome to the official website for more information.

Back to list

Back to list