The Basic Knowledge of Lead-Free Solder Paste (4)_Shenzhen Fitech

The Basic Knowledge of Lead-Free Solder Paste (4)_Shenzhen Fitech

Continued from "The Basic Knowledge of Lead-Free Solder Paste (3)"

After reflow soldering is completed, the pads need to be cleaned, and then the reliability test is completed. The packaging manufacturer's requirement for soldering is that the solder joints produced should have a uniform and round shape. Moreover, the solder joints need to meet specified reliability requirements, such as thermal conductivity and mechanical strength. The shape of lead-free solder joints has a significant impact on their reliability, so whether there are defects can be determined by observing the solder joint appearance. Many factors will lead to poor shape of lead-free solder joints.

1. Pad Cleaning

The activator component of water-soluble lead-free solder paste will generate acidic residues after soldering. If it is not removed in time, it will continuously corrode the solder joints. The cleaning processes mostly adopted by the market include water-based cleaning and semi-water-based cleaning. Water-based cleaning is more widely used due to its excellent cleaning performance. The PCBs can be soaked, sprayed or ultrasonic treated to achieve cleaning purposes. The PCBs are then rinsed with 25-60 ℃ deionized water. There is also a kind of lead-free solder paste called no-clean solder paste, which is less active but is free of cleaning after soldering. The manufacturers can choose whether to clean according to the actual packaging requirements.

2. Shape Defects and Influences

After soldering, the bottom of the solder joint is connected to the substrates, and the top is connected to the components. The appearance of solder joints is usually spherical. Different shapes have different effects on performance. The width and height of lead-free solder joints can be measured through the vertical profile. The packaging industry has requirements on the aspect ratio of lead-free solder paste solder joints. Generally, the aspect ratio of solder joints is between 1.3-1.5. A proper aspect ratio can prevent solder joints from the damage of solder masks.

2.1 The consequences of improper solder volume

The amount of solder paste has the most direct influence on the shape of solder joints. For example, the amount of solder paste is too small. Insufficient solder paste on the pad will result in poor solder joint strength. The cause of insufficient solder volume is that the bonding pad or stencil is covered by impurities, resulting in a smaller contact area during printing. Besides, the viscosity of lead-free solder paste increases when it is exposed to the air. As a result, the solder paste cannot pass through the apertures, leading to inadequate solder volume. Another case is the phenomenon of excessive solder paste. If the stencil apertures and thickness are too large, excessive solder volume may occur, which will lead to the bridging of adjacent solder paste points, especially on pads with fine pitch.

2.2 Solder paste slump and bridging

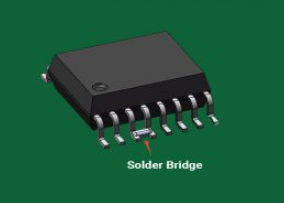

There are many causes of the slump, including large solder volume, poor demoulding property, and low viscosity of solder paste. If the amount of solder paste is too large, it is easy to cause a slump during melting, and it will bridge with adjacent solder joints. Inconsistent size and poor roughness of the steel mesh will lead to poor demoulding performance, resulting in slump and bridging. In addition, the low viscosity of lead-free solder paste means that it has better fluidity, and its ability to maintain shape is weaker. Hence, It is easy to collapse after printing and will diffuse outward after heating, leading to bridging. There are also some reasons, such as high printing pressure, mounting offset, and small solder paste alloy particles, which can also cause collapse and bridging. Solder paste bridging will have a great impact on the circuit, mainly reflected in the short circuit between solder joints.

Figure 1. Solder bridging effect.

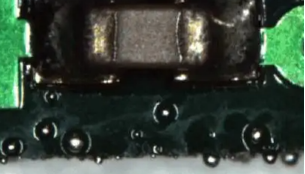

2.3 A large number of tin beads appear near the solder joints

The oxidation of solder paste and impurities on the pad surface will lead to the formation of fine solder beads, which will affect the soldering reliability. Solder powder with small particle sizes is easier to be oxidized, and the probability of solder bead formation is greater. The formation of solder beads is also related to the poor activity of the flux. The low flux activity cannot effectively reduce the oxide layer. Consequently, the solderability is degraded. In addition, if the temperature of the reflow oven rises rapidly, the evaporation of the flux solvent will be accelerated, and the solder particles will splash out to form small solder beads. The reflow of solder paste without sufficient rewarm will also trigger the formation of solder beads.

Figure 2. Solder bead formation near the soldering surface.

Fitech is a world-leading provider of microelectronics and semiconductor packaging materials solutions. Fitech’s solder paste, epoxy solder paste, and other solder products have an outstanding wetting effect, narrow powder particle size distribution, and high post-soldering reliability. Welcome to the official website for more information.

Back to list

Back to list