The Role of Solder Alloys and the Physical Properties of Solder Paste before Curing

1. The role of alloys in solder paste

Solder alloy is the main component of solder paste and an important factor affecting the quality of solder paste. Solder alloy composition determines the peak temperature of the reflow profile for SMT components.

In the process of reflow soldering, the solder powder is melted at the reflow temperature. Relying on wetting force and surface tension, the solder alloy aggregate fills the soldering seam and achieves a reliable connection between the two base metals. The solder alloy is the critical bridge to connect the soldering metals.

2. What are the physical properties of solder paste before curing?

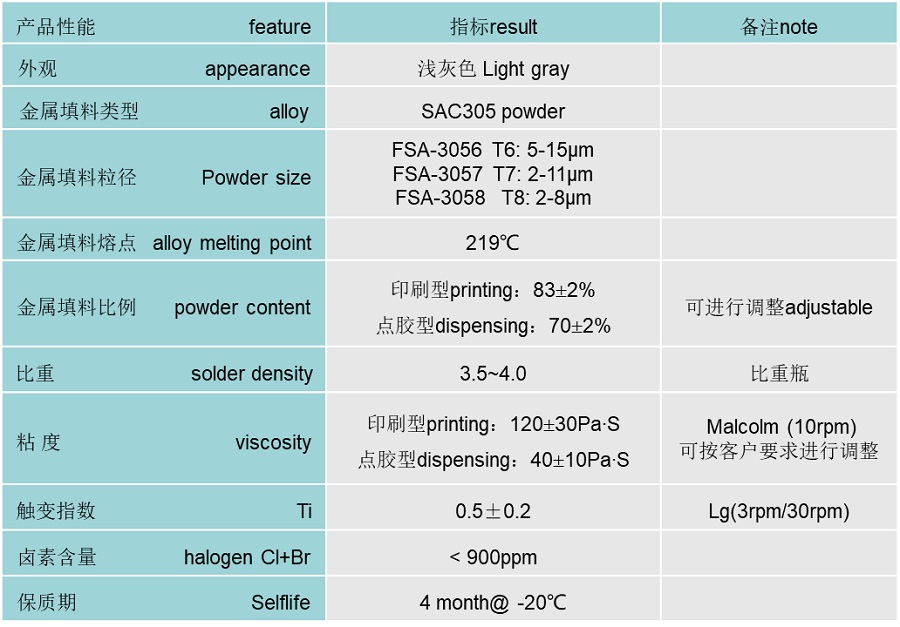

Let’s take Fitech’s SAC305 epoxy solder paste (also called epoxy solder adhesive) FSA-305 product physical property parameter table as an example:

Fitech's epoxy solder paste FSA-305 physical parameters (if you want to know more details, please contact us.)

2.1. Solder paste appearance. Normal solder paste is usually light gray.

2.2 Determining the type of metal component in the solder paste.

The metal component in solder paste plays a leading role in soldering. Therefore, it is necessary to determine which alloy type solder paste products to choose according to soldering conditions and usage conditions.

2.3 Solder paste metal particle size.

In the assembly of electronic products, different pad sizes and component pitches affect the selection of solder paste alloy with different sizes.

Due to the rapid development of electronic equipment technology, components and packaging have become increasingly miniaturized and sophisticated. The more precise the components, the smaller the chip size, and the smaller the stencil and pad sizes. Therefore, the solder paste with a smaller particle size is required to ensure that the solder paste can smoothly pass through the stencil apertures under the printing pressure.

The alloy particle size and oxidation status influence the performance of the solder paste. At present, the particle sizes of solder paste used in precision packaging are T6 (5-15um), T7 (2-11um), and T8 (2-8um). Solder paste with large particle size is easy to clog the stencil, which affects the printability of the solder paste and is not suitable for the printing of PCBs with fine pitches, but the price is relatively cheap. Solder paste with small particle size has better printability, but it is prone to solder paste slump, especially in the case of large printing thickness. The production process requirements are high, and the price is expensive. Therefore, the particle size of the solder paste should be reasonably selected in practical applications with reference to the IC pin spacing and cost on the PCBs.

2.4 Melting point of solder paste alloy.

The melting point of the alloy in the solder paste determines the peak reflow temperature.

2.5 The proportion of alloy in solder paste

The proportion of alloy in the solder paste affects the solder paste properties such as the slump resistance of the solder paste products.

2.6 Specific gravity of solder paste

2.7 Solder paste viscosity

Solder paste viscosity affects characteristics such as solder paste tackiness.

2.8 Solder paste thixotropic index

Solder paste thixotropic index affects printing performance.

2.9 Halogen content

The halogen content affects the application of solder paste. Many countries currently require solder paste to meet environmental protection standards such as RoHS.

-End-

*Disclaimer: Except for "reprinted" articles, the copyright of the original content published on this site belongs to Shenzhen Fitech. Without consent and authorization, it may not be reproduced, reproduced, quoted, changed, or published. This article is originally created by the author, and the content of the article is the author's personal opinion. "Reprint" is only to convey a different point of view and does not mean approval or support for the point of view. If there is any infringement, please contact us, and we will delete it!

Back to list

Back to list