The Role of the Combination of Matrix Material and Active Agent in Lead-Free Solder Paste Flux during Reflow Soldering

Keywords: metal surface, lead-free solder paste, flux, substrate, solder, soldering, flooding, surface, oxidation, interfacial tension

The types and functions of matrix materials in lead-free solder paste are mentioned earlier. At the same time, we know that there are more than matrix materials in the lead-free solder paste flux system. This article briefly introduces the role of the combination of matrix materials and active agents in the lead-free solder paste flux in the reflow soldering process.

(1) Removing the oxide film on the surface of the base metals.

The rosin in the solder paste flux melts and covers the soldering surface of the base metals before the solder paste alloy melt. The active substances remove the metal surface. The scavenging effect of rosin in solder paste flux on copper oxides can be described by the following chemical reaction formula.

Since rosin is an organic acid, it has the function of cleaning the metal surface as a base material of solder paste. However, because the cleaning effect is relatively weak, it is necessary to add active substances to the solder paste flux in order to further improve the cleaning result.

(2) Preventing reoxidation of base metals during heating.

With the increase in soldering temperature, the reoxidation on the base metal surface becomes more serious. Therefore, the solder paste flux must provide protection to the cleaned metal surface. The solder paste flux should form a thin film on the entire base metal surface, wrap the base metal, and isolate it from the air to prevent oxidation of the metal during soldering.

(3) Reducing the surface tension during solder paste soldering.

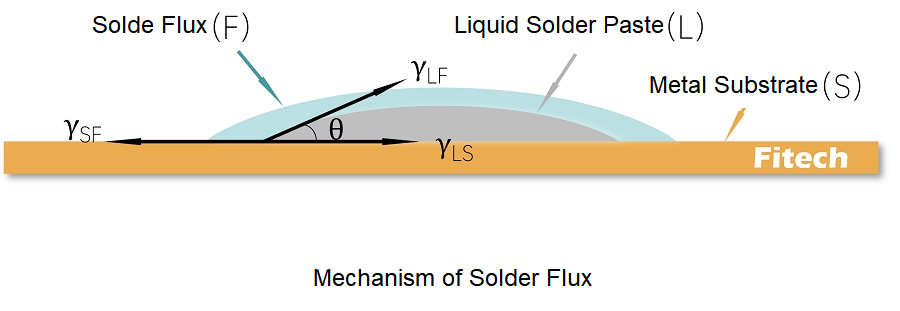

The solder paste flux in the solder area can affect the surface energy balance by promoting solder paste flooding and reducing the surface tension and contact angle of solder paste soldering.

γSF>γLF is the prerequisite for the liquid to wet solid. Compared with the clean surface without oxide film, the surface free energy of solid metal covered with oxide film is significantly reduced, resulting in a non-wetting phenomenon of γSF<γLF. The use of solder paste flux in soldering can remove the oxide film of solder paste alloy particles and metals, improving wettability. As shown in the figure below, when the liquid solder paste and the metal are covered with a layer of flux, the interfacial tension is changed.

The equilibrium equation for liquid solder paste alloy to stop flooding:

γSF=γLS+γLFcosθ

cosθ=(γSF=γLS)/γLF

γSF-the interfacial tension between the metal and the flux;

γLF-interfacial tension at the interface of liquid solder and flux;

γLS-the interfacial tension between the liquid solder and the metal.

It can be seen from the formulas that in order to improve solder paste wettability (reduce the θ angle), it is necessary to increase γSF or decrease γLF and γLS. In addition to removing the metal substrate oxide film to increase γSF, solder paste flux can reduce the interfacial tension γLF between liquids.

(4) Heat transfer.

Generally, there are many gaps in the welded joints. The air in these gaps acts as a thermal insulator during the soldering process, resulting in poor heat transfer. If these gaps are filled with flux, heat transfer can be accelerated, and thermal equilibrium can be reached quickly.

(5) Promoting the flow of liquid solder paste alloy.

After the preheated solder paste flux enters the reflow zone, the activity increases sharply, the viscosity drops sharply, and secondary flooding on the metal surface is formed. The solder paste spreads rapidly on the metal surface. The flooding force formed by the secondary flooding process allows the solder paste flux adheres to the liquid solder, thereby dragging the flooding process of the liquid metal.

-End-

Fitech is a comprehensive solder paste supplier integrating production, sales, research, and service of solder paste, epoxy solder paste, and ultra-fine alloy solder powder, which has a complete product line from alloy solder powder to application products. The products cover ultra-fine lead-free solder paste, high/low-temperature solder paste, die bond solder paste, gold-tin solder paste, etc. Fitech is an electronic-grade packaging material manufacturer that can manufacture T2-T10 ultra-fine alloy solder powder and is the unit in the formulation of solder powder standards by the Ministry of Industry and Information Technology. Welcome to inquire about and customize products.

*Disclaimer: Except for "reprinted" articles, the copyright of the original content published on this site belongs to Shenzhen Fitech. Without consent and authorization, it may not be reproduced, reproduced, quoted, changed, or published. This article is originally created by the author, and the content of the article is the author's personal opinion. "Reprint" is only to convey a different point of view and does not mean approval or support for the point of view. If there is any infringement, please contact us, and we will delete it!

Back to list

Back to list