Types, Functions and Mechanisms of Active Substances in Solder Paste Fluxes

The active substances in the flux have an important impact on the performance and the use of lead-free solder paste. This article briefly discusses the common active substances in lead-free solder paste flux. What’s more, the role and mechanism of the active substances in the solder flux will be mentioned.

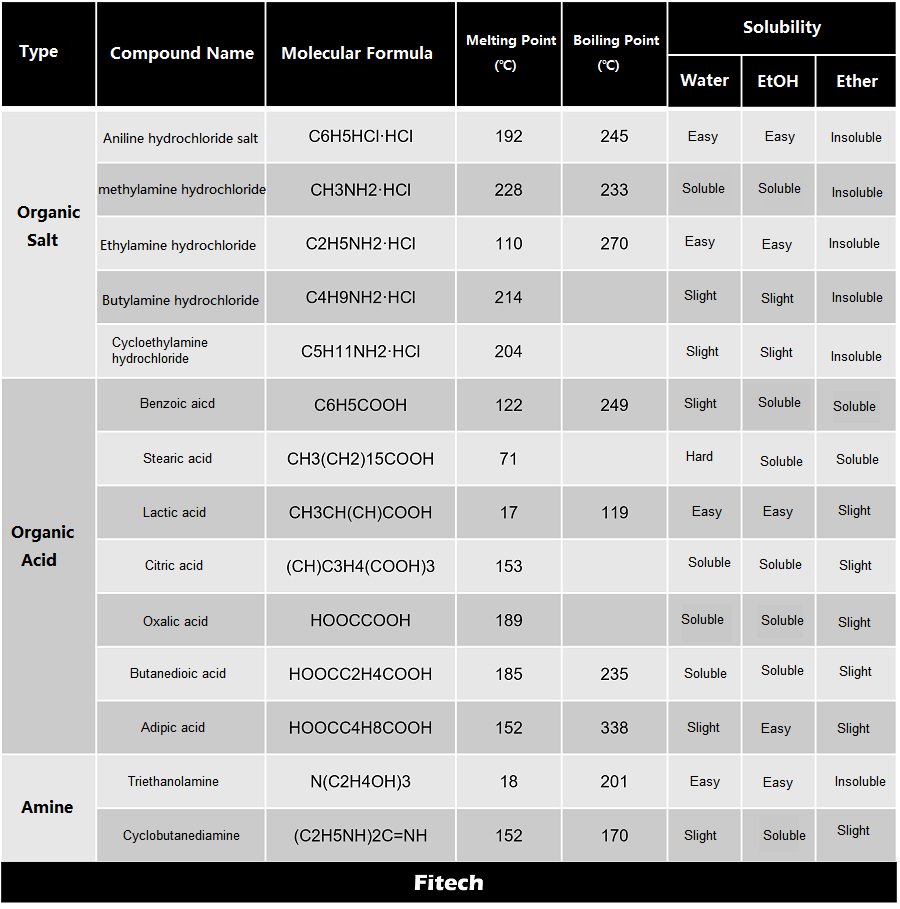

In the early stage, active substances of solder paste flux mostly consist of halogen compounds with powerful reducing effects. However, in recent years, in order to ensure reliability, more organic acids and organic salts with stable reducing ability are used as active substances in lead-free solder paste flux, which are concluded in Table 1.

What is the role of the active substances in solder paste flux? What is the mechanism for these effects?

The molten alloy solder in the solder paste can flow along the surface of the base metals during the soldering process, which is the premise of obtaining reliable solder joints, and wetting is the premise of the flow. In order to allow the molten solder paste fully wet the base metals, it is necessary to remove the oxides and adsorbed gases in the soldering area prior so that the molten solder paste and the metal surface mutually achieve pure-metal contact. Therefore, the active substances in the solder paste flux should completely remove the oxides and adsorbed gas layers on the surface of the base metals before being wet by the molten solder paste.

Wetting/spreading occurs when the free energy of the post-wetting formed system is lower than the free energy before wetting. In other words, when the molten solder paste wets the base metals, the energy on the surface of the base metals must be higher than that of the solder paste. Obviously, the lower the surface energy of the molten solder paste or the higher the surface energy of the base metals, the more favorable the wetting process. At this time, the solder paste flux expands the surface energy of the base metal and interacts with the appropriate metallurgical reaction to reduce the free energy at the contact surface. This is the role of the flux in the wetting process.

In short, the active substances in the solder paste flux should have a chemical activity that can remove the oxide film and have a physical activity that improves the ability of the molten solder to flow along the surface of the base metals.

The content of active substances in the solder paste flux accounts for about 0.2% to 1.0% by mass. Considering the influence of residue on soldering reliability, organic acids or organic salts decomposed at the soldering temperature are mostly used. The content of halogen active substances in the flux for reflow soldering is generally 0 to 0.2 wt%.

-End-

Fitech is a comprehensive solder paste supplier integrating production, sales, research, and service of solder paste, epoxy solder paste, and ultra-fine alloy solder powder, which has a complete product line from alloy solder powder to application products. The products cover ultra-fine lead-free solder paste, high/low-temperature solder paste, die bond solder paste, gold-tin solder paste, etc. Fitech is an electronic-grade packaging material manufacturer that can manufacture T2-T10 ultra-fine alloy solder powder and is the unit in the formulation of solder powder standards by the Ministry of Industry and Information Technology. Welcome to inquire about and customize products.

*Disclaimer: Except for "reprinted" articles, the copyright of the original content published on this site belongs to Shenzhen Fitech. Without consent and authorization, it may not be reproduced, reproduced, quoted, changed, or published. This article is originally created by the author, and the content of the article is the author's personal opinion. "Reprint" is only to convey a different point of view and does not mean approval or support for the point of view. If there is any infringement, please contact us, and we will delete it!

Back to list

Back to list