Soldering Performance of Epoxy Sn42Bi58 Solder Paste_Shenzhen Fitech

Soldering Performance of Epoxy Sn42Bi58 Solder Paste_Shenzhen Fitech

With the development of semiconductor technology, there is a trend towards miniaturization of electronic devices in electronic packaging, so the reliability of solder joints has become increasingly important. When the size of the solder joint decreases and the soldering temperature increases, the growth rate of interface IMCs is fast. Due to the excessive growth of brittle IMCs, the anti-drop, shear, and thermal cycling performance of solder joints will decrease. Sn42Bi58 solder paste is a eutectic solder paste that can be applied in low-temperature soldering (low thermal shock) environments and can provide good yield strength and creep resistance.

Epoxy flux

However, due to the tendency of Sn42Bi58 solder paste to accumulate Bi and reduce the reliability of solder joints, it is necessary to adopt a method to improve the strength of solder joints. Li et al. proposed adding curable epoxy resin to the Sn42Bi58 solder paste system to prepare resin-reinforced composite solder paste. The principle is that after the alloy components of epoxy-based solder paste are melted and solidified on the copper plate, the epoxy resin solidifies and wraps the solder joint. Li et al. compared the wettability, shear strength, and conductivity of epoxy-based solder paste with traditional solder paste.

Performance of epoxy-based Sn42Bi58 solder paste

Wettability

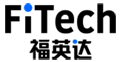

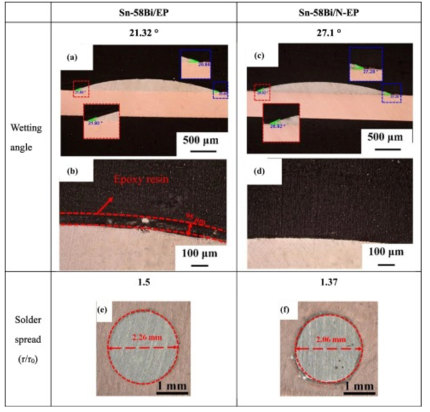

From the figure below, it can be seen that the surface of the epoxy-based Sn42Bi58 solder joint is covered by cured epoxy, and the wetting angle formed is about 20°, which is much smaller than that of ordinary Sn42Bi58 solder paste. During the preheating and linear heating stages, the viscosity of epoxy resin rapidly decreases with increasing temperature. As a result, the fluidity of the flux is improved, which is conducive to better expansion of the flux and thus improves the wettability of the substrate.

Figure 1. Wetting angle of epoxy solder paste and ordinary solder paste on copper plate.

Shear strength

Epoxy resin can effectively increase the thrust of Sn42Bi58 solder joints by about 25%, playing a certain role in improving the bonding strength of solder joints. There is a continuous cured epoxy layer around the Sn42Bi58 solder joint. When subjected to shear, the epoxy resin can absorb external forces and first shear and fracture, indicating that the epoxy resin can effectively absorb some external forces and enhance the overall shear strength of the solder joint. In addition, temperature has a significant impact on the strength of epoxy resin, and 180℃ can achieve the optimal curing of epoxy resin.

Figure 2. (a) Shear strength of epoxy solder paste and ordinary solder paste; (b) The shear strength of epoxy solder paste at different temperatures.

Conductivity

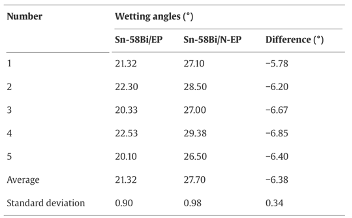

Comparing epoxy Sn42Bi58 solder paste with ordinary Sn42Bi58 solder paste, it can be found that the conductivity of the two is similar, so it can be considered that the cured epoxy resin has almost no negative effect on the conductivity of the solder joint.

Figure 3. Epoxy solder paste and regular solder paste.

Fitech’s solder paste

To meet the market demand for highly reliable solder joints, Shenzhen Fitech has independently developed epoxy-based solder paste products with excellent shear strength and conductivity.

Reference

Liu, X.G., Yang, X.J., He, D.Y. & Ma, L.M. (2023). Study on the properties of epoxy-based Sn-58Bi solder joints. Microelectronics Reliability, vol.148.

Back to list

Back to list