The Impacts of Laser and Reflow Soldering on Solder Joints_Shenzhen Fitech

The Impacts of Laser and Reflow Soldering on Solder Joints_Shenzhen Fitech

With the advent of the "post-Moore era", heterogeneous integration based on small chips will become the mainstream of semiconductor packaging. Small chips tend to be packaged in 3D directions to achieve flexible modular integration and system-on-chip integration. It should be considered that 3D packaging will bring some problems. For example, high-power electronic components often dissipate large amounts of heat during use, which requires a high melting point solder to maintain the thermal stability of the interconnect. However, the interconnection of some heat-sensitive components requires low-temperature solder. Some of these substrates have high heat sensitivity and cannot withstand high temperatures and prolonged heating in reflow ovens. Laser soldering can be used as an alternative soldering process due to its localized and non-contact heating, rapid temperature changes, and no need for flux.

Experimental design

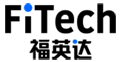

The rapid temperature change and short soldering time (several seconds) during laser soldering will significantly affect the interface IMC and the microstructure of the solder matrix, thereby affecting the reliability of the solder joints. To study the effects of laser soldering and reflow soldering on IMC growth, Wu et al. used SAC305 solder balls with a diameter of 100μm to be soldered on a silicon-based interposer containing Ni-P UBM. The Ni-P layer was sputtered with a 0.1μm thickness Au layer. The laser soldering energy is 7.5mJ. The peak reflow temperature is 250°C for reflow soldering.

Figure 1. (a) Silicon-based interposer; (b) Schematic diagram of laser soldering; (c) Reflow profile; (d) Shear test.

Experimental results

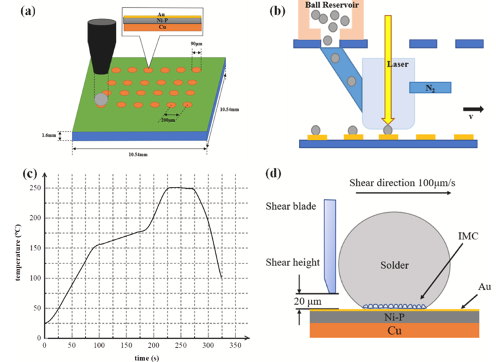

There are obvious differences in the interface IMC of the initial SAC305 microbumps obtained by different soldering processes, as well as the thickness and morphology of the solder matrix. The interface IMC after laser soldering is granular with a thickness of 0.6μm, while the IMC after reflow soldering is needle-shaped with a thickness of 1.3μm. At the same time, there are small granular (Cu, Ni)6Sn5 particles in the laser-soldered micro-bump matrix, while relatively large IMC particles are found in the reflow-soldered micro-bump matrix. In addition, Ni-P UBM is largely consumed during reflow rather than laser soldering.

Figure 2. SEM images of SAC305/Ni-P microbumps. (a1-a3) Laser soldering; (b1-b3) Reflow soldering.

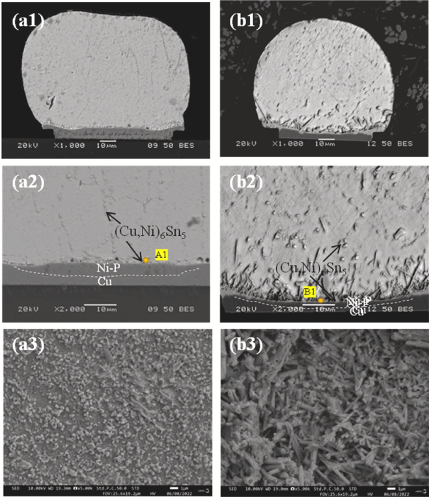

Figure 3 shows the microstructure of laser-soldered and reflowed SAC305 microbumps after isothermal aging at 150°C at different times. It can be found that regardless of the soldering process, the thickness of IMC increases with aging time. The (Cu, Ni)6Sn5 of laser-soldered micro-bumps changes from small granular to scallop-shaped, while the IMC in the reflowed micro-bumps gradually grows from needle-shaped to short rod-shaped. In addition, due to the small size of laser-soldered (Cu, Ni)6Sn5 and the large grain boundaries, atomic diffusion is more likely to cause the grain growth rate to be significantly faster. However, the thickness of the laser-soldered IMC is still much thinner than that of reflowed IMC.

Figure 3. SEM images of microbumps after aging for 100h, 200h, and 400h. (a1-b3) Laser soldering; (c1-d3) Reflow soldering.

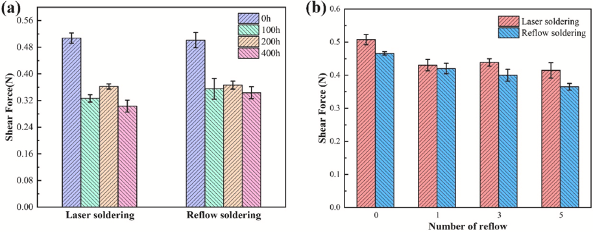

For as-reflowed situations, the shear strength of laser-soldered microbumps is slightly higher than that of reflow welding microbumps. Wu et al. believe that laser welding precipitates more tiny particles, which can inhibit crack expansion. When the aging time reaches 100h, the microbump shear strength of both soldering processes decreases significantly. As the aging time further increases, the change in shear strength of the microbumps becomes less obvious. In addition, for multiple reflows, laser soldering can make the shear strength of microbumps higher. As the number of reflows increases, the shear strength of both laser and reflow soldering microbumps decreases slightly.

Figure 4. Effect of different aging times on microbump shear strength.

Reference

Wu, Y., Zhang Z.J., Chen, L.D. & Zhang, S.Y. (2024). Comparative study on the bonding property of laser and reflow soldered Sn-3.0Ag-0.5Cu/Ni–P microbumps after isothermal aging and multiple reflowing. Journal of Material Research and Technology, vol.29.

Back to list

Back to list