Advantages of Solder Paste Containing Bismuth compared to SAC305 Solder Paste_Shenzhen Fitech

Advantages of Solder Paste Containing Bismuth compared to SAC305 Solder Paste_Shenzhen Fitech

SAC305 alloy is considered an important metal component of lead-free solder due to its relatively high melting point. Solder joints prepared with SAC305 solder can maintain good condition when subjected to thermal cycles and mechanical stress, so they are of great use in many industries such as the automotive and aerospace industries. However, the reliability of solder joints will weaken due to the influence of temperature and external force. Studies have shown that micro alloyed solder joints containing Ni, Bi, In and Sb exhibit improved mechanical properties, such as higher shear and tensile strength, and microstructural stability after aging.

Experimental design

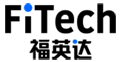

The impact of aging on the reliability of solder joints is obvious. Generally, during the aging process of several months, the strength of the solder joints will decrease significantly. Since Bi affects the strength of solder joints, Belhadi et al. (2023) added Bi to SAC305 solder and observed the evolution of the mechanical properties of SAC solder joints under aging and shearing to determine the role of Bi. For this experiment, the PCB test board size was 30 mm × 30 mm, the spacing between pads was 3mm and the pads were OSP surface treated. Three different solder balls (SAC305, SAC-3Bi, and SAC-6Bi) are reflow soldered on the pads through the ball placement process. The shear strain rates were 0.008, 0.8, and 8 s-1, and the aging temperature was 150°C.

Figure 1. PCB test board (left) and reflow profile (right).

Experimental results

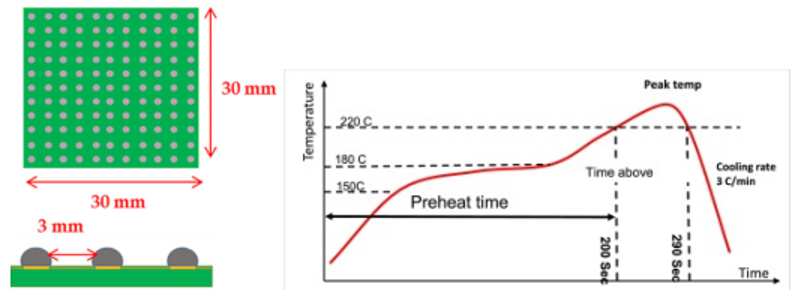

Figure 2 shows the average ultimate shear strength (USS) of each unaged solder as a function of Bi concentration at a shear strain rate of 0.8s-1. Compared with SAC305 alloy, SAC-6Bi has the highest USS. The USS of SAC-3Bi and SAC-6Bi increased by 122% and 127% respectively compared with SAC305. The increase in shear strength is caused by solid solution hardening and precipitation hardening due to the presence of Ag and Bi.

Figure 2. USS of different solders at a shear strain rate of 0.8s-1.

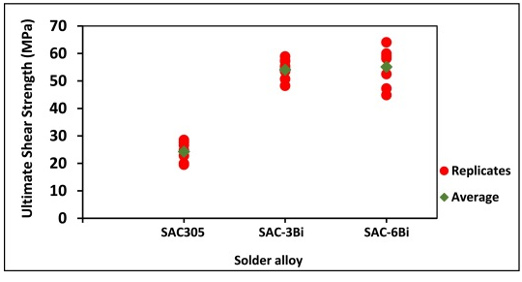

The USS of the three solder alloys increases with the increase of shear strain rate, among which the USS of Bi-containing SAC solder is still better than that of ordinary SAC305. The increase in USS is due to the viscoplasticity of the solder alloy. Solder viscoplasticity refers to the time-varying plastic deformation of solder that is affected by strain rate. At higher strain rates, the viscoplastic characteristics of the solder are more obvious, resulting in more plastic deformation and higher USS of the solder joints.

Figure 3. USS of solder at different shear strain rates.

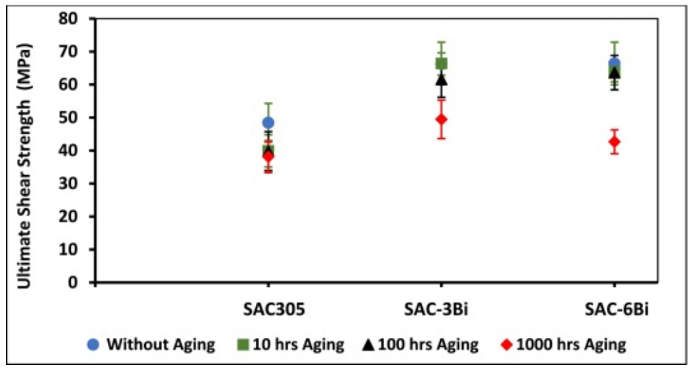

Aging will have a significant impact on the shear strength of solder joints. It can be found that when the aging time increases, the solder containing more Bi will show a greater decrease in shear strength. After aging for 100h, the solder with the highest shear strength is SAC-6Bi, followed by SAC-3Bi. After aging for 1000h, the USS of SAC305 decreased by 26%. The USS of SAC-Bi solder has a higher degradation, among which the strength of SAC-6Bi has the most obvious decrease, which is reduced by about 57%.

Figure 4. USS of solder after aging (shear strain rate 0.8s-1).

Due to the low solubility of Bi in Sn, when the Bi content exceeds the solubility limit in the Sn matrix, solder containing Bi will precipitate during the aging process. The precipitation of Bi will cause the brittleness problem of the solder joints and cause the solder joints to undergo brittle fracture under the action of strain. For SAC-3Bi solder joints, after aging for 1000h, due to the increased solubility limit of Bi at 150°C, part of Bi can still be dissolved in the solid solution, and the degree of embrittlement of the solder joints is low. However, since the SAC-6Bi solder joints contain more Bi, the solder joints become more embrittled after aging, so the shear strength decreases significantly.

Reference

Belhadi, M.E.A., Hamasha, S. & Alahmer, A (2023). Effect of Bi content and aging on solder joint shear properties considering strain rate. Microelectronics Reliability, vol.146.

Back to list

Back to list