Influence of Copper Nanoparticles on Solderability and Microstructure of SnBi Solders_Shenzhen Fitech

Influence of copper nanoparticles on solderability and microstructure of SnBi solders

With the development of lead-free solders, SnAgCu and SnBi solders have become the main alternatives to traditional tin-lead solders for different packaging scenarios. Eutectic SnBi58 solder has been widely used in industry, especially in low-temperature soldering, due to its low melting point (139°C) and low cost. However, the brittleness of SnBi solder limits its application in high-reliability packaging. Therefore, it is important to suppress the brittleness of SnBi solder and improve its mechanical properties.

Refining the solder microstructure is one of the effective methods to improve the solder quality. Considering the thermal coefficient of expansion (TCE) mismatch of the whole package, increasing the cooling rate during the soldering process is not a feasible method to refine the SnBi solder. Therefore, the addition of nanoelement particles is considered to be an effective way to refine the solder microstructure of solder joints.

Copper is a common added element in SnBi lead-free solders. During the reflow soldering process, Cu forms Cu6Sn5 intermetallic compounds with molten Sn. However, the solid-liquid reaction may affect the distribution of Cu nanoparticles in the mixed solder paste and lead to a decrease in the wettability of the solder. In addition, increasing the copper content in the solder may decrease the copper diffusion rate between the solder and the pad.

In order to investigate the effect of copper nanoparticle addition on the solderability of SnBi solder, Liu et al. printed the solder paste onto FR-4 boards with a Cu-OSP surface finish as well as onto unwetted substrates by stencil printing method using a typical soldering process. Soldering was performed using typical soldering processes. The solder powder was mixed with Cu nanoparticles by mechanical mixing for 30 minutes. The concentrations of Cu nanoparticles in the solder paste mixes were 0, 0.5, 1, 2 and 3 wt%.

Experimental results

Solderability of SnBi-nano-Cu solder pastes

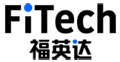

Figure 1 shows the DSC curves of SnBi eutectic solder paste and SnBi-3nano Cu solder paste. As can be seen from the figure, the two solder pastes show similar DSC curves. The solid-phase line temperature is about 136°C for both types, but the liquid-phase line temperature is slightly different.

Figure 1. DSC curves of SnBi and SnBi-nano copper solder pastes.

Wettability

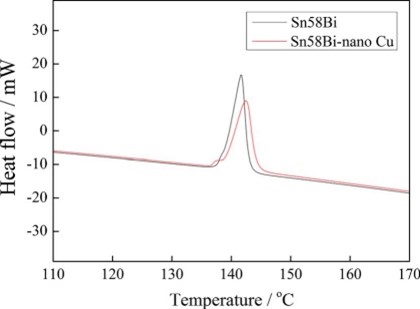

The wettability of the solder paste is evaluated by the spreading rate SR, which is expressed as:

SR= (D-H)/D*100

where D is the equivalent diameter of the solder paste, which can be measured by reflow soldering on a non-wetted substrate, and H is the height of the solder joint after the paste has wetted onto the copper substrate. According to the spreading rate equation, the higher the SR value, the better the wettability of the solder paste. As shown in Figure 2, the SR value of SnBi solder paste is about 82%. The SR values of SnBi-nano Cu solder pastes are around 70-72 %. This indicates that the addition of nano Cu to SnBi solder paste leads to a decrease in the wettability of the copper substrate.

Fig. 2. Spreading ratio of nano Cu solder pastes with different contents.

Microscopic solder joint structure of SnBi-nano-Cu/Cu

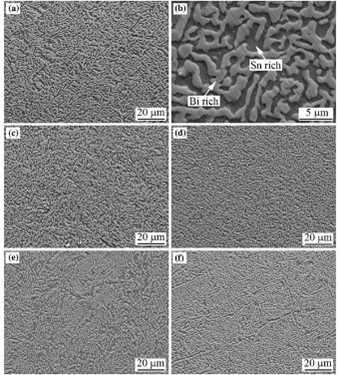

Figure 3 shows the microstructure of the solder block in SnBi-nano Cu/Cu solder joints. As shown in Fig. 3 a, b, the microstructure of the solder mass in the SnBi/Cu solder paste is mainly based on Sn-rich and Bi-rich phases. With the addition of Cu nanoparticles in SnBi solder pastes up to 0.5 and 1 wt%, the microstructure of the solder body showed a tendency of refinement as shown in Fig. 3 a, c, and d. The microstructure of the solder body in the SnBi/Cu solder pastes is mainly based on Sn-rich and Bi-rich phases. Solid Cu6Sn5 intermetallic compound particles are formed during the heating process and increase the nucleation point of Bi grains and SnBi eutectic phase formed during the cooling process. Appropriate nano-copper addition facilitates the grain refinement of the solder block. However, the grain refinement was limited as the Cu nanoparticles addition was increased to 2-3 wt%.

Fig. 3. Microstructure of SnBi-nano Cu/Cu solder bumps: a, b SnBi/Cu; c SnBi-0.5 wt% nano-Cu; d SnBi-1 wt% nano-Cu; e SnBi -2 wt% nanocopper; f SnBi-3 wt% nanocopper.

References

Liu, Y., Zhang, H., & Sun, F. (2015). Solderability of SnBi-nano Cu solder pastes and microstructure of the solder joints. Materials in Electronics, 27(3), 2235–2241.

Back to list

Back to list