Effect of solder paste viscosity on porosity and mechanical properties of surface mount solder joints_Shenzhen Fitech

Effect of solder paste viscosity on porosity and mechanical properties of surface mount solder joints

Surface mount technology is one of the most important technologies in the electronics industry, where components are attached to a printed circuit board by means of solder paste. However, organic matter in the solder paste can create bubbles during the heat reflow process, leading to the formation of pores in the solder joints. The porosity reduces the strength, electrical and thermal conductivity of the solder joints, and even causes fatigue cracks, affecting product reliability.

So, how to control the porosity in the solder paste? The viscosity of solder paste is a key factor.Tian et al. selected four different viscosity ranges of solder paste. Through X-ray radiography, thermogravimetric analysis and shear test, the relationship between solder paste viscosity and surface mount solder joint porosity was investigated.

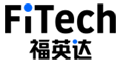

With X-ray radiography, it can be observed that the higher the viscosity of the solder paste, the greater the porosity of the solder joint.

Figure 1. Typical X-ray photograph of a solder joint:(a) 49.2-49.9 pa s,(b) 94.6-94.7 pa s,(c) 130.2-159.6 pa s 和 (d) 235.5-238.1 Pa s。

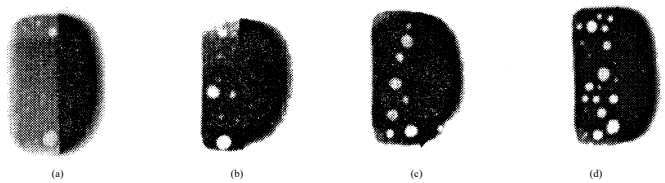

Figure 2 shows the thermogravimetric (TG) curves of solder pastes with different viscosity ranges. The solder pastes with lower viscosity ranges have higher organic evaporation rates before the metal alloy melts, but lower evaporation rates after the metal alloy melts.

Fig. 2. Plot of solder paste weight loss rate versus reflow temperature derived from TGA. The viscosity range increases from curve i) to curve iv). 49.2-49.9 Pa s,ii) 94.6-97.6 Pa s,iii) 130.2-159.6 Pa s,iv) 235.5-238.1 Pa s。

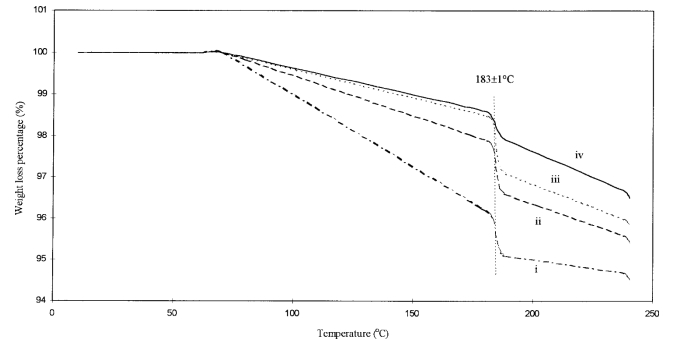

Fig. 3. Weight loss of solder pastes with different viscosity ranges during the TG process: i) 49.2-49.9 Pa s,ii) 94.6-97.6 Pa s,iii) 130.2-159.6 Pa s 和 iv) 235.5-238.1 Pa s。

From Fig. 3, it can be seen that the weight loss rate of the solder paste with lower viscosity range is higher than that of the paste with higher viscosity range during the TG process. The weight loss rate of solder paste increases with decreasing viscosity range, and the weight loss rate gradually increases from 3.3% to 3.5%.

This result indicates that solder pastes with higher organic content (lower viscosity range) have a greater organic evaporation rate than solder pastes with lower organic content.

For solder pastes with a lower viscosity range, most of the organic matter evaporates before the metal melts, and less vapor remains when the metal begins to solidify. The reason for this is that an increase in organic content reduces paste viscosity, which makes the paste more fluid and allows the metal powder and additives to mix more evenly. This in turn facilitates the escape of volatile gases.

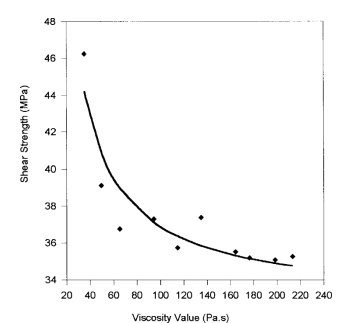

Figure 4 shows the relationship between solder joint shear strength and paste viscosity. In general, the shear strength of the solder joints increases as the paste viscosity decreases. The solder paste viscosity varies between 35.2 and 213.3 Pa s, while the shear strength varies between 46.25 and 35.27 MPa, respectively, reflecting a significant change of 30%. This trend is more pronounced when the paste viscosity is lower than 50 Pa s . The solder joints made of solder paste with lower viscosity are more resistant to shear due to their lower porosity.

Fig. 4. Relationship between shear strength of solder joints and paste viscosity.

In order to obtain more reliable and robust solder joints with high shear strength, solder pastes with a higher organic content (lower viscosity) should be used.

With years of experience and technology in lead-free solder paste production, Shenzhen Fuyingda can provide high quality and reliable solder paste for different viscosity, alloy and particle size requirements. If you want to know more about our solder paste products and services, welcome to call us, we will be happy to serve you.

Y. Tian, Yan C. Chan, J. K. L. Lai, and Sally T. F. Pak. (1997). The Effect of Solder Paste Viscosity on Porosity and Mechanical Properties of Surface Mount Solder Joints. IEEE Transactions on Components, Packaging and Manufacturing Technology—Part B, Vol. 20.

Back to list

Back to list