Impact of Solder Paste Printing on Reflow Soldering Success Rate_Shenzhen Fitech

Impact of solder paste printing on the success rate of reflow soldering

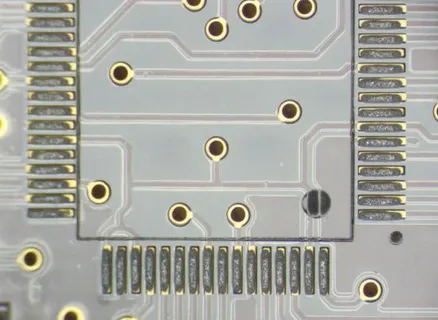

According to statistics, in the PCB design is correct, components and printed board quality is guaranteed under the premise of surface assembly quality problems in nearly 70% is out of the solder paste printing process. Printing position is correct or not (printing accuracy), the amount of solder paste, the amount of solder is uniform, whether the graphic of the paste is clear, there is no sticking, PCB surface is stained by the solder paste, etc., are directly affecting the quality of PCB assembly welding. There are many factors that affect the quality of printing, the main factors include:

Stencil quality: stencil printing is contact printing, so the thickness and opening size of the stencil to determine the amount of solder paste printing. Too much solder paste will result in bridging, while too little paste will result in insufficient solder or false soldering. The shape of the stencil opening and the smoothness of the opening also affect the release quality. The opening of the stencil must be flared downward, otherwise the solder paste will be brought out from the chamfer of the flare when demolding.

Printing process of solder paste: The viscosity, printability (rollability, transferability), thixotropy, and service life at room temperature of the solder paste will all affect the printing quality. If the printability of the solder paste is not good, in severe cases, the solder paste just slides on the stencil, in which case it is impossible to print the solder paste at all.

Printing process parameters: Solder paste is a non-Newtonian fluid with viscosity. When the squeegee advances at a specific speed and angle, it exerts a certain pressure on the solder paste, pushing it to roll in front of the squeegee, thus injecting the required pressure into the stencil. The sticky friction of the paste creates shear where the squeegee meets the stencil, and this shear helps the paste to be injected smoothly into the stencil. There are certain mutual constraints between squeegee speed, squeegee pressure, stencil angle and paste viscosity, so only the correct control of these parameters can ensure the printing quality of the paste. For example, too much squeegee pressure will lead to paste pattern sticking, and too fast printing speed will easily lead to insufficient amount of paste. Failure to remove the solder paste left at the bottom of the stencil in time may result in solder paste contamination of areas outside the pad during printing, and all these factors may lead to soldering defects such as bridging, virtual soldering and solder beads.

Equipment Accuracy: When printing high-density fine-pitch products, the printing accuracy and repeat printing accuracy of the printing machine will also play a role. If the printing machine is not equipped with a visual alignment system, even if the manual graphic alignment is very accurate when the PCB pad graphics and stencil mesh graphics completely overlap, but still can not solve the problem of PCB processing errors.

The use of recycled solder paste, management and environmental factors: environmental temperature, humidity and environmental hygiene have an impact on the quality of solder joints. Recycled solder paste and new solder paste should be stored separately, high ambient temperature will reduce the viscosity of the paste, humidity is too high when the paste will coefficient of moisture in the air, humidity is too small will accelerate the solvent evaporation in the paste, the environment, dust mixed into the paste will make the solder joints to produce pinholes.

By correctly controlling these factors, you can improve the solder paste printing process, improve the quality of PCB assembly soldering.

Back to list

Back to list