Low-Temperature Ultra-Fine-Pitch Solder Paste for mLED: Tesla Light technology Decryption

Low-Temperature Ultra-Fine-Pitch Solder Paste for mLED: Tesla Light technology Decryption

Solder Paste and Ultra-Fine Solder Manufacturer-Shenzhen Fitech is a comprehensive solder paste supplier integrating production, sales, research, and service of solder paste, epoxy solder paste, and solder powder. Fitech is the leading unit for the formulation of solder powder standards of the Ministry of Industry and Information Technology. Fitech's products include ultra-fine lead-free printing solder paste, ultra-fine lead-free dispensing solder paste, ultra-fine lead-free jetting solder paste, ultra-fine lead-free pin transfer solder paste, no-clean solder paste, water-soluble solder paste, high-temperature solder paste, medium-temperature solder paste, low-temperature solder paste, etc. Fitech can manufacture electronic-grade packaging solder powders with particle sizes from T2-T10.

On December 24, 2021, Tesla launched a major update for car owners, including the new UI of the car v11 and the FSD Beta V10.8 version. After the update, the car owners were pleasantly surprised to find that the light show function was added, in which the headlights displayed a "TESLA" pattern. One reason is that Tesla has not emphasized this matter in the publicity before, and people are instantly pleasantly surprised when they see this situation. Another reason is whether it is a matrix LED headlight or a laser headlight, which is basically a gimmick from "light factory" Audi. Due to the high installation cost, it is still far from ordinary consumers. The lighting function for Tesla in Model 3 and Model Y models sold at prices from 200,000 to 300,000 should be conscientious. Contrary to the display in the circle of friends, Tesla is so low-key, which makes people feel that this is by no means simple.

The author has been engaged in the LED industry for many years. Out of technical curiosity, I have verified relevant public information through multiple parties, hoping to restore the technical route of Tesla's headlight source.

TESLA Headlights

According to public information, Tesla's headlights are manufactured by HELLA, a well-known German spare parts supplier, and the supplier of the light-emitting unit is Samsung Electronics.

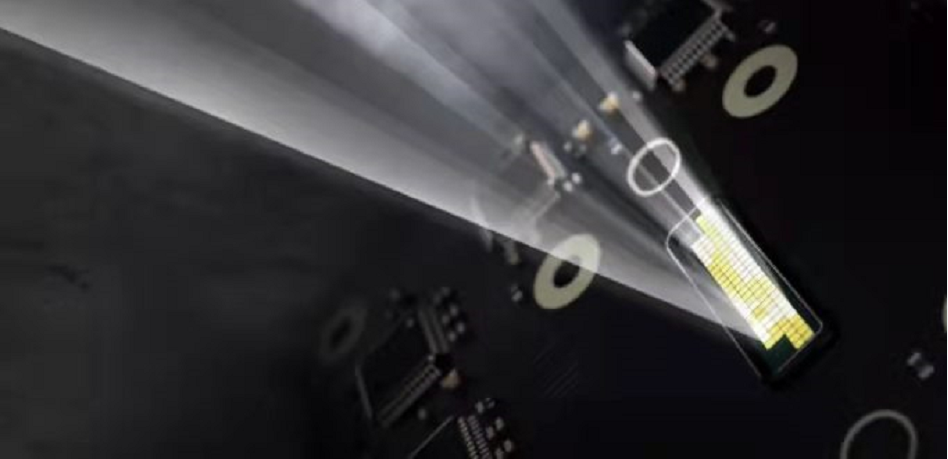

In April 2021, Samsung released a new generation of automotive light source PixCell LED modules, which will be applied to smart headlights in cars.

According to Samsung, the newly developed PixCell LED is an ultra-compact LED solution suitable for automotive smart headlights, which can realize lighting control through a smaller light-emitting area and light-dark contrast.

In addition, Samsung's products reduce the light-emitting area to 1/16 of that of ordinary smart headlights, making the lamp smaller, helping to improve the fuel efficiency of the cars, and increasing the design flexibility of the lamps.

PixCell LED Module(Source:Website of Samsung)

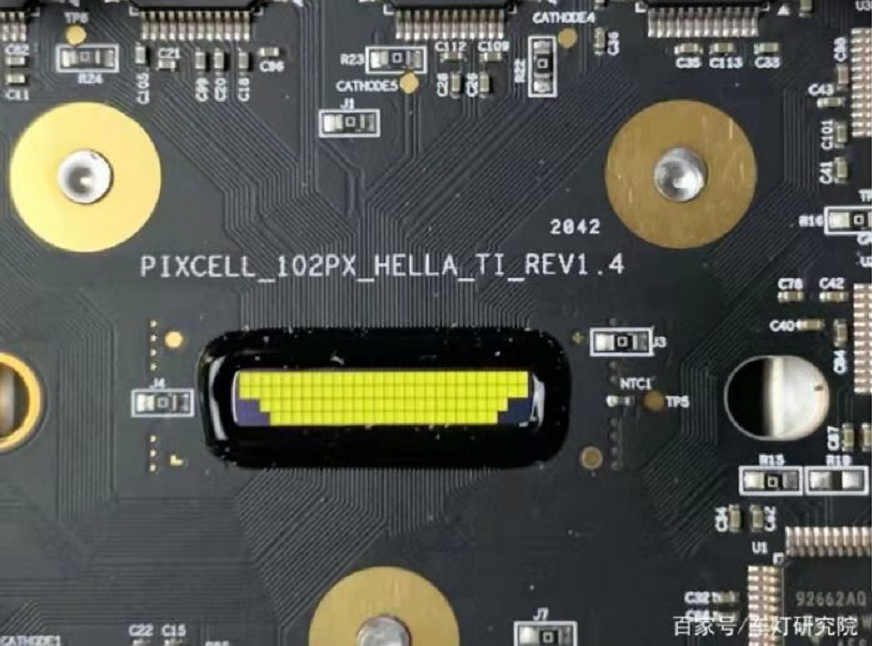

From the dismantling analysis released by the Auto Lamp Research Institute, Tesla does use Samsung’s PixCell LED technology. Therefore, it is necessary to dig a little deeper into the technology.

Tesla headlight dismantling light source(Source:车灯研究所)

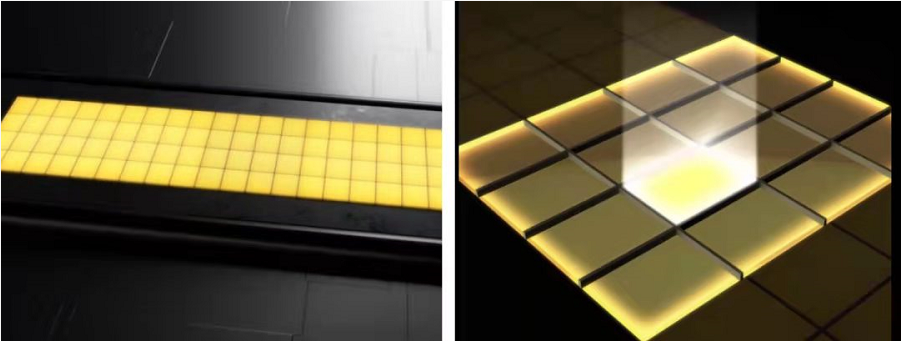

In order to improve the display effect of PixCell LED and prevent crosstalk between adjacent light sources, a silicon wall partition is set up between each pixel.

PixCell LED(Source:Samsung's Website)

From the final display effect, each pixel unit in the PixCell LED achieves a single-sided light-emitting effect. According to previous knowledge, the chip segment achieving this light-emitting effect is mainly thin-film chips, such as vertical thin-film chips, thin-film flip chips (TFFC), etc. The packaging side can also use flip chip + CSP ( Chip Scale Package) technology. The light around the chip is blocked and reflected by the white wall so that the side light is reflected to the front, and the effect of single-sided light can also be achieved.

SAC Solder Paste SACS Solder Paste SnBiAg Solder Paste SnBiAgSb Solder Paste SnBiAgX Solder Paste SnBi Solder Paste BiX Solder Paste AuSn Solder Paste SnSb Solder Paste SnPb Solder Paste Anisotropic Conductive Paste Ultra-Fine-Pitch Flux

PixCell LED seems to have similarities with CSP technology, but the white wall (high reflective materials such as titanium dioxide) is replaced by a silicon wall. From the schematic diagram of the promotion, the silicon wall is higher, and the fluorescent film is not covered on the silicon wall. This design actually reduces pixel crosstalk and improves pixel resolution.

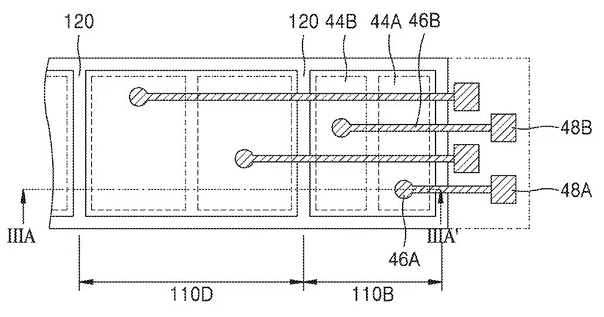

In order to further understand how the PixCell LED is implemented, we searched many ways and finally found a patent recently disclosed by Samsung.

Published patent number: US17373038

Patent name: LIGHT-EMITTING DEVICES HEADLAMPS FOR VEHICLES AND VEHICLES INCLUDING THE SAME

The patent details the basic design concept of the PixCell LED core light-emitting device.

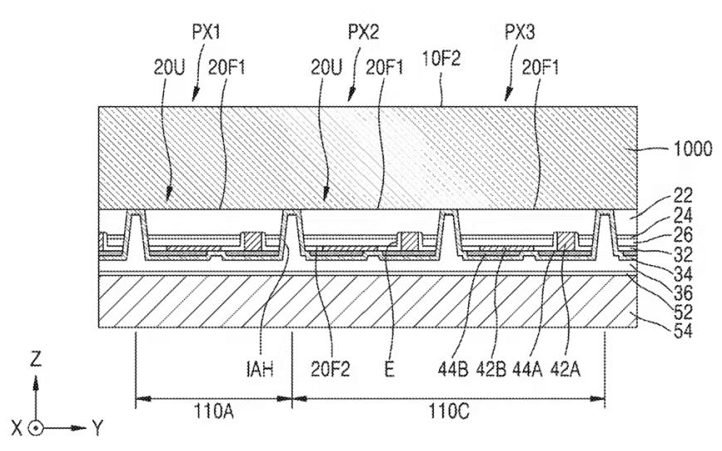

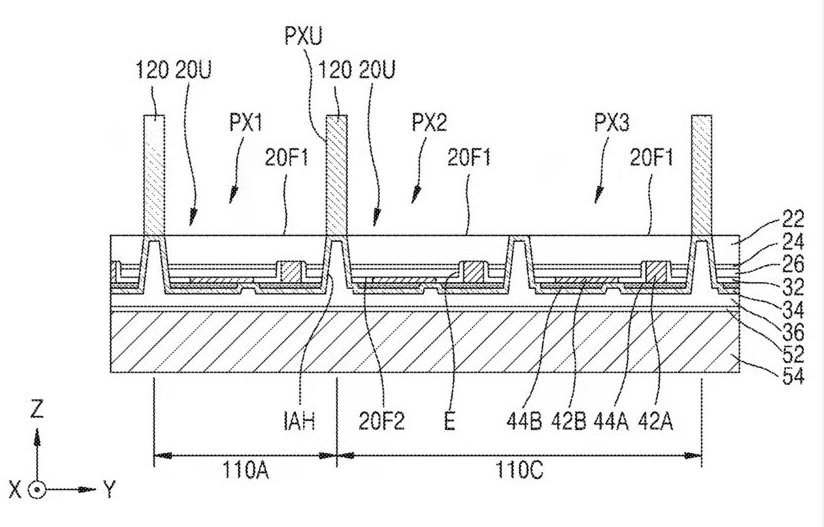

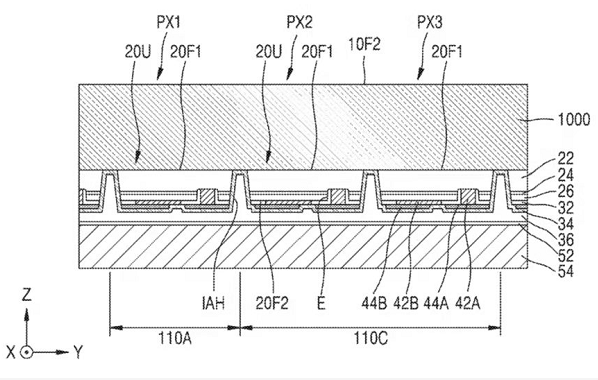

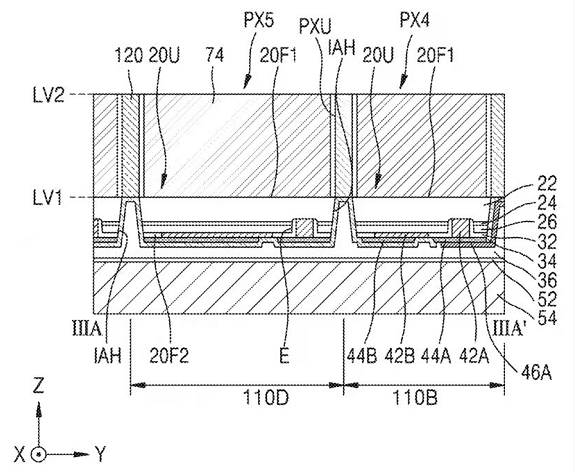

The basic design idea adopts TFFC technology and wafer-level packaging (WLP) concept.

Silicon substrate 1000 forms silicon walls 120 by etching

And made a reflective layer 72 on the sidewall of the silicon wall

The silicon walls are filled with light-transmitting material 74, enabling wafer-level packaging

The electrodes of the actual TFFC are drawn out through the wires. This design goes beyond the design scope of the TFFC and advances the wafer-level packaging technology one step further.

In terms of process flow and final design, Samsung’s PixCell LED adopts a silicon substrate epitaxy process. The chip structure adopts a TFFC-like structure with a silicon wall and is made into a white light chip through WLP technology.

Although the patent is not limited to silicon substrates, it is difficult for actual sapphire and silicon carbide substrates to have the effect of selective substrate removal. Silicon substrates are naturally opaque, which is beneficial to prevent adjacent chips from interfering with light.

The content presented in this patent is highly innovative and can expand the vision of developers. For practitioners who have been engaged in the development of thin-film chips for a long time, the implementation of this solution may not be as complicated as imagined, but it is indeed relatively novel. Of course, it should take a lot of energy and investment to reach the automotive level and enter the pre-installation market.

Compared with the relatively mature sapphire and gallium nitride on silicon carbide epitaxy, the GaN-On-Si (gallium nitride on silicon) epitaxy technology used in this scheme has a large lattice mismatch between gallium nitride and silicon. The quality of the gallium nitride crystal grown by this technical route is poor. The difference in crystal quality will be reflected in reliability and performance to a certain extent. Judging from user feedback, Tesla has some problems with burnt headlights after upgrading the light show, and it cannot be ruled out that it may be related to this reason.

In a sense, Samsung's PixCell LED can be recognized by leading car companies and enter the automotive pre-installation market, which is definitely a milestone event for GaN-On-Si technology based on silicon substrates.

Perhaps Tesla knew in advance that the GaN-On-Si technical solution had risks, but it could indeed achieve a smaller light-emitting area and contrast ratio. Therefore, Tesla's adoption of this technology is in line with its usual technology-driven style of doing things.

In addition to using GaN-On-Si technology, PixCell LED combines WLP, TFFC, Drive On Board (DOB), and other technologies and has evolved and advanced it forward. PixCell LED is the crystallization of Samsung’s cross-innovation in the field of light-emitting chips and semiconductors. Its innovative vision and innovative capabilities are worthy of reference and learning from domestic manufacturers.

Of course, GaN-On-Si is not the only way to realize matrix LED headlights. For example, laser lift-off technology is used to realize TFFC chips. Domestic companies such as Changelight, Sanan, and Shineon have been deeply involved in the field of thin film chips for many years. In terms of light efficiency and reliability, thin film chips based on sapphire laser lift-off technology will have more advantages than silicon substrate LED technology.

Source: LEDinside

Back to list

Back to list