How to Choose and Measure the Right Solder Paste Powder Size for Microchip Packaging?

1. What is the importance of choosing the right particle size of solder paste?

Proper solder powder size is of great significance to the reliability of microchip soldering. First of all, a suitable solder paste size can ensure sufficient solder paste printing volume. A solder paste with an excessively large particle size cannot guarantee sufficient solder paste printing volume, thus questioning the reliability of microchip soldering. The application of small-size solder paste is not cost-effective. In addition, the size and size distribution of solder paste alloy have an impact on the release performance, thixotropy, slump resistance, and generation of solder balls of solder paste. Therefore, a solder paste product with excellent size distribution is highly necessary.

2. Relevant standards for solder powder size

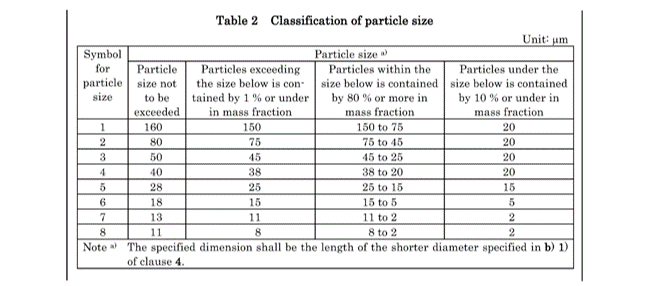

The Japanese Industrial Standard JIS Z 3284-1 "Industrial Standard for Solder Paste Part 1: Type and Quality Classification" clearly defines the T1 to T8 solder paste based on particle sizes. The standard regulates the size of solder paste from three aspects, including the specified solder powder size, the ratio exceeding the maximum and minimum specified size, and the maximum particle size. The details are shown in the following table.

3. How to measure solder powder size

The Japanese Industrial Standard JIS Z 3284 "Industrial Standards for Solder Paste" provides four standard methods for measuring the size of solder paste, which are the microscope measurement method, sieving method, laser diffraction method, and optical image analysis method. The laser diffraction and optical image analysis methods are suitable for measuring the solder paste size of T6 and above.

Fitech uses a laser particle size distribution analyzer to measure the size and size distribution of ultra-fine solder paste by laser diffraction method. Details are shown in the figure below.

Taking T7 solder powder as an example, the particle size concentration of Fitech's T7 ultra-fine solder powder is extremely high (99.63% at 2-11um), which is much higher than the standard of JIS Japanese Industrial Standard (80% ) and other similar products in the market.

4. How to choose solder paste with suitable particle size

To select the appropriate solder particle size, the pad size should be first determined. According to general principles, if it is a square or rectangular pad, the short side needs to be able to accommodate at least 5 solder particles (particle size according to JIS Z 3284-1, Table 2). If the pad is a circle, the diameter needs to accommodate at least 8 alloy solder powder balls to ensure soldering reliability. When using anisotropic conductive paste, the inter-pad spacing is required, and inappropriate conductive particle size may cause short circuits. The alloy powder sizes of anisotropic conductive paste include T8 (2~8um), T9* (1~5um), and T10* (1~3um).

* [T9 and T10 are Fitech's corporate standard]

The above introduction briefly describes how to choose the appropriate particle size of solder paste and how to measure the particle size of solder paste. If you want to know more about the selection of solder paste products, solder paste standards, and solder paste testing, you can follow us and contact us at any time.

Back to list

Back to list