Selection of Solder Paste Solder for Ultra-Fine-Pitch mLED Display Packaging

Selection of Solder Paste Solder for Ultra-Fine-Pitch mLED Display Packaging

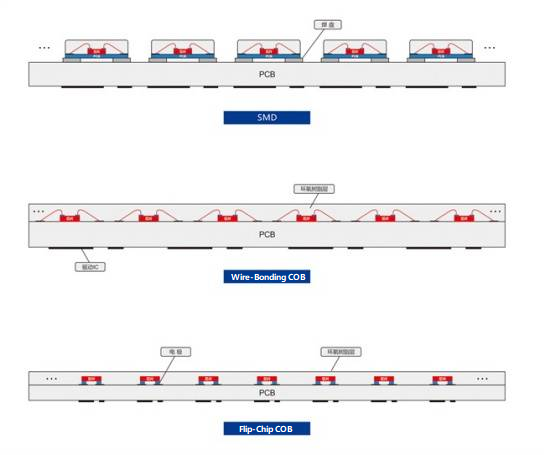

LED packaging refers to the process of mechanically protecting LED chips and realizing electrical interconnection through a series of manufacturing processes to form LED devices. There are three main packaging forms used in LED displays on the market, including SMD, IMD, and COB.

1. Surface Mounted Device

The SMD devices used in the LED surface mount include one LED chip of blue, green, and red. The three colors of LED chips are packaged into SMD and then undergo a surface mounting process. Each SMD device is a pixel.

SMD devices can be divided into TOP SMD devices and CHIP SMD devices according to the light output and packaging method.

TOP SMD device adopts a bowl-cup mechanism, dispensing packaging, and emits light on one side. CHIP SMD device adopts PCB plane structure, molding package, and emits light on five sides.

The advantages of SMD packaging technology are the high maturity of the placement process, the mature supply chain, the outstanding mixing effect, the elimination of the Mura effect, and the high repairability. However, SMD packaging technology has disadvantages such as large sizes and pitches of SMD devices, poor electrical connection performance, poor thermal cycle impact performance, and unreasonable flatness.

According to the characteristics of SMD surface mounting technology, traditional lead-free solder paste solder can be used.

2、LED Are Directly Interagetd on The Substrate(Chip On Board)

COB packaging integrates packaging and display technologies, eliminating SMT die bonding process.

The COB packaging process has the advantages of small chip sizes, not limited by the bracket size, smaller pixel pitch, good electrical connection performance, excellent thermal cycling performance, and high flatness.

According to the pixel pitch shrinkage, COB packaging should adopt T6, T7, and T8 ultra-fine solder pastes for soldering. The pixel pitch of flip-chip COB packaging is further reduced. The flip-chip COB display products on the market have achieved the pixel pitch of P0.5 or even P0.4. For such a small pad and pixel pitch, ultra-fine solder paste is an essential solder material because it brings better reliability and economy. If COB is further developed, the size of the chip pad will be reduced to below 60um or 50um. In addition, the pixel pitch will be reduced to below 350um, which is far beyond the ability of T7 solder paste. In order to ensure soldering and product stability, T8 ultra-fine solder paste should be used. However, the preparation of high-quality ultra-fine solder powder and T8 ultra-fine solder paste are technical problems that foreign companies have not yet solved.

Fitech has started technical layout many years ago. Fitech successively overcame key technical difficulties and applied for relevant patents. After years of experience accumulation, Fitech’s T8 solder paste solder (2-8um) was launched in 2020. It was quickly recognized by many domestic and foreign manufacturers and became commercialized. In 2022, Fitech will launch Fitech™ mLED 1330 solder paste containing T8 SnBiAg alloy for mini-LED and micro-LED packaging.

3、IMD Matrix Integrated Packaging(Integrated Matrix Device)

IMD devices are characterized by "N in 1", which means that N pixels are packaged in one IMD device. For example, 2 pixels packaged in one IMD device are "2 in 1", etc. Similar to SMD, each pixel contains one blue, green, and red LED chip.

IMD is a compromise of SMD and COB packaging. It has the advantages of easy maintenance, light separation, anti-collision, and high reliability. At present, the pixel pitch of the product is about 0.9mm.

The Fitech™ mLED 1330 solder paste developed by Fitech adopts T8 solder powder, which is especially suitable for COB packaging with high electrical connection performance, excellent thermal cycle shock performance, and ultra-fine-pitch.

Back to list

Back to list