Dispensing Solder Paste: Core Components of PWS Earphones and Dispensing Process

Solder Paste and Ultra-Fine Solder Manufacturer-Shenzhen Fitech is a comprehensive solder paste supplier integrating production, sales, research, and service of solder paste, epoxy solder paste, and solder powder. Fitech is the leading unit for the formulation of solder powder standards of the Ministry of Industry and Information Technology. Fitech's products include ultra-fine lead-free printing solder paste, ultra-fine lead-free dispensing solder paste, ultra-fine lead-free jetting solder paste, ultra-fine lead-free pin transfer solder paste, no-clean solder paste, water-soluble solder paste, high-temperature solder paste, medium-temperature solder paste, low-temperature solder paste, etc. Fitech can manufacture electronic-grade packaging solder powders with particle sizes from T2-T10.

We can find that there are a reduced number of wired headphones in life, but more and more true wireless stereo (TWS) headphones appear. The increasing number of phones cancel the 3.5mm headphone jack. TWS earphones are highly portable. Hence, consumers much prefer TWS earphones.

TWS Market

TWS Market

In terms of shipments, the wired earphones have a similar shipment to the wireless earphones in the past year (44%). Last year, wireless Airpods 2 accounted for 30% of the total earphone shipment. The second is the wired AirPodsPro, followed by the wireless GalaxyBudslive, which accounted for 2.79%. Regarding regions, wired earphone is very popular in China and India, while the wireless type is the most popular in Europe and the United States. The earphone models released in 2021 are mostly wired, accounting for 70.37%.

A variety of TWS earphones.

Domestic and foreign manufacturers have followed up with such a huge market share and joined the production and sales of wireless earphones.

TWS Core Components and Packaging

TWS Core Components and Packaging

Because of wireless design, the wireless earphones have to contain the most functional modules and the largest battery volume in the original small limited space, resulting in the accurate design of the internal components and the small structure of the components. The requirements for anti-fall and anti-vibration capabilities are also strict.

TWS earphones are small, including limited internal space and complicated processes. The requirements for the component precision and the level of module technology are relatively high, which requires tacit cooperation and a clear labor division of upstream and midstream manufacturers. The key components are mainly included in ODM/OEM, SiP, batteries, and chips. The important chips include master control chips, power chips, memory chips, etc.

The dispensing process can play a very good role in bonding:

1. Filling the gaps and reaching the minimum volume;

2. Using various types of adhesive in different places to meet requirements such as anti-vibration, anti-fall, and waterproof;

3. Reducing design verification and manufacturing costs.

Compared with mobile phone products, TWS earphones dispensing are relatively simple. The complex situations are as follows:

1. There are many arcs in the dispensing path: Different from the direct mechanism design of the mobile phones, the TWS earphones have a small and round appearance, multiple arc paths, tight interiors, and a number of arcs, resulting in a slightly complicated dispensing path.

2. There are many types of adhesive used in dispensing. Due to the high value of mobile phones and high use frequency, waterproofing mainly adopts methods such as injection molding and shielding fasteners. Less adhesive is used. TWS earphones are of low value. In order to reduce the cost, various types of adhesive are used for bonding to achieve simple waterproofing, which leads to the numerous kinds of adhesive used in the assembly process.

TWS Industry Chain

TWS Industry Chain

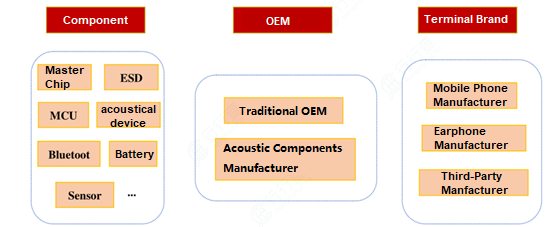

The upstream component manufacturers in the TWS earphone industry chain mainly include wireless earphones and charging.

The components of wireless earphones include Bluetooth chips, memory chips, flexible circuit boards (FPCs), etc.

The charging box mainly includes microcontrollers, power management ICs, lithium electronic batteries, etc.

The midstream of the industry chain consists of OEM/ODM manufacturers, which have the ability to process acoustic precision components.

The downstream of the industrial chain is divided into three categories. The first is mobile phone brands represented by Apple, Huawei, and Xiaomi. The second is traditional earphone manufacturers represented by Sennheiser and Sony. The third is the third-party manufacturers represented by iQiyi and NetEase Cloud.

Back to list

Back to list