MEMS Application Trend and Market Status in China

MEMS Application Trend and Market Status in China

According to report from MEMS Consulting, MEMS microphone manufacturer Yutai Technology announced on February 25 that the company will handle private equity cases and issue 11,272 private equity ordinary shares, of which 1,000 will be subscribed by MediaTek Xuda Investment. If the shareholders are authorized, the shareholding ratio of MediaTek Group will reach 20%, which means that Yutai Technology will become a member of the Pan-MediaTek Group.

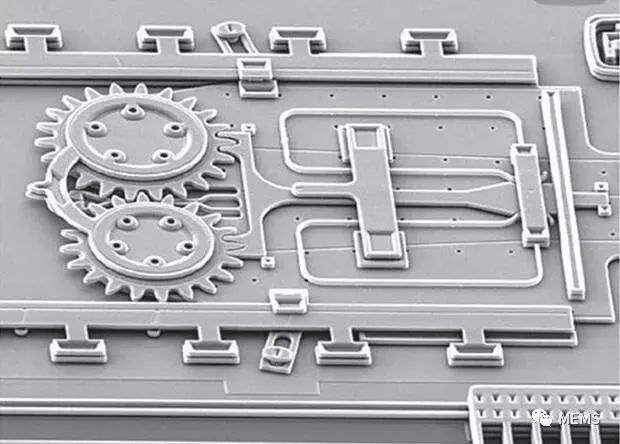

The MEMS sensor industry chain includes chip design, manufacturing, packaging and testing, solution provision, and system application. Traditional semiconductor technology and materials are used in domestic system application to form a micro-device integrating micro-sensors, micro-actuators, micro-mechanical structures, signal processing and control circuits before the interface, communication and power supply.

MEMS Sensor Application Trends

The MEMS acoustic sensor is an acoustic sensor that uses MEMS technology to convert acoustic signals into electrical signals. It is widely used in smart phones, wireless headsets, tablet computers, smart wearable devices, smart homes, and other consumer electronics and automotive electronics fields.

For example in the field of automotive electronics, perception is a prerequisite for autonomous driving. The comprehensive and high-sensitivity perception of unmanned vehicles to the external environment is one of the keys for safe vehicle driving. It performs real-time identification through sensors and networks installed in and around the vehicle. Therefore, autonomous vehicles cover sensors. The higher the level of autonomous driving, the higher the performance requirements of the sensors to help the vehicle react in milliseconds.

Current Situation of MEMS Sensors in China

Compared with developed countries and regions such as Europe, the United States and Japan, China's MEMS industry started late. In the early 1990s, with the support of the Ministry of Science and Technology, the Ministry of Education, the Chinese Academy of Sciences, the National Natural Science Foundation of China, and the former National Defense Science and Technology Commission, China began to research and explore MEMS. After more than a decade of development, China has accumulated a certain foundation and technical reserves in micro-sensors, actuators and multiple micro-system prototypes, and has achieved surprising results in some fields. Although the technology is still behind of the international advanced levels, and there is a lack of companies with core technologies, China has laid a good foundation for the further development of MEMS.

The fate must be in Chinese people own hands, otherwise the MEMS sensor development process will be thorny. The conflict between Russia and Ukraine has attracted widespread attention around the world. The media focus on the war trend and subsequent impacts. It expresses the predictions and judgments of economic, energy, aerospace, cultural, and sports institutions for the future.

However, MEMS sensors face many process issues.

1. The thickness of the MEMS sensor structure layer is inaccurate. 2. The shape of the side wall is not good. 3. Adhesion problem. 4. Internal stress and stress gradient. 5. Cracks. 6. The releasing failure. 7. Sticky problem. 8. Inaccurate material properties.

A large cause of MEMS sensor process problems is the packaging materials. Improper selection of packaging materials can increase MEMS packaging stress and lead to process reliability issues. The solder pastes required for MEMS packaging have high requirements on curing temperatures, mechanical properties, accuracy, void ratios, reliability, and other properties. Fitech provides packaging solder paste solutions for different MEMS sensors to meet the performance and economic needs.

Back to list

Back to list