Effects of Composition and Properties of Solder Paste on Applications

Solder paste is used for microelectronics and semiconductor soldering. The application characteristics of solder paste directly affect the quality of soldering. The application characteristics of solder paste are determined by the composition and composition parameters. Let's take a look at the influences of the composition and properties on the solder paste applications.

1. Composition and parameters of solder paste

Solder paste is mainly composed of solder alloy powder and flux (please refer to: "The composition of flux in solder paste and its requirements" for flux composition). The parameters such as solder alloy powder, flux, and solder paste affect the application characteristics of solder paste from different aspects.

1.1 The main parameters of solder alloy powder are 1) composition of solder alloy powder; 2) impurities; 3) particle shape; 4) particle size; 5) particle size distribution; 6) oxidation state; 7) melting point.

1.2 The main parameters of flux are 1) composition; 2) content; 3) boiling point; 4) halogen content ;5) thixotropic volume; 6) solvent content; 7) conductivity.

1.3 The main parameters of solder paste are 1) density; 2) viscosity; 3) water absorption.

2. Solder paste assembly characteristics requirements

2.1 Before printing: storage stability

2.2 Printing-before reflow soldering: 1) Mold release; 2) Thixotropy; 3) Viscosity.

2.3 During reflow: 1) Wetability; 2) Solder ball; 3) Solder spatter; 4) Quick drying.

2.4 After reflow soldering: 1) Cleanability; 2) Beautiful component surface; 3) Corrosion; 4) Insulation resistance; 5) Mechanical strength

3. The influences of solder paste composition on applications

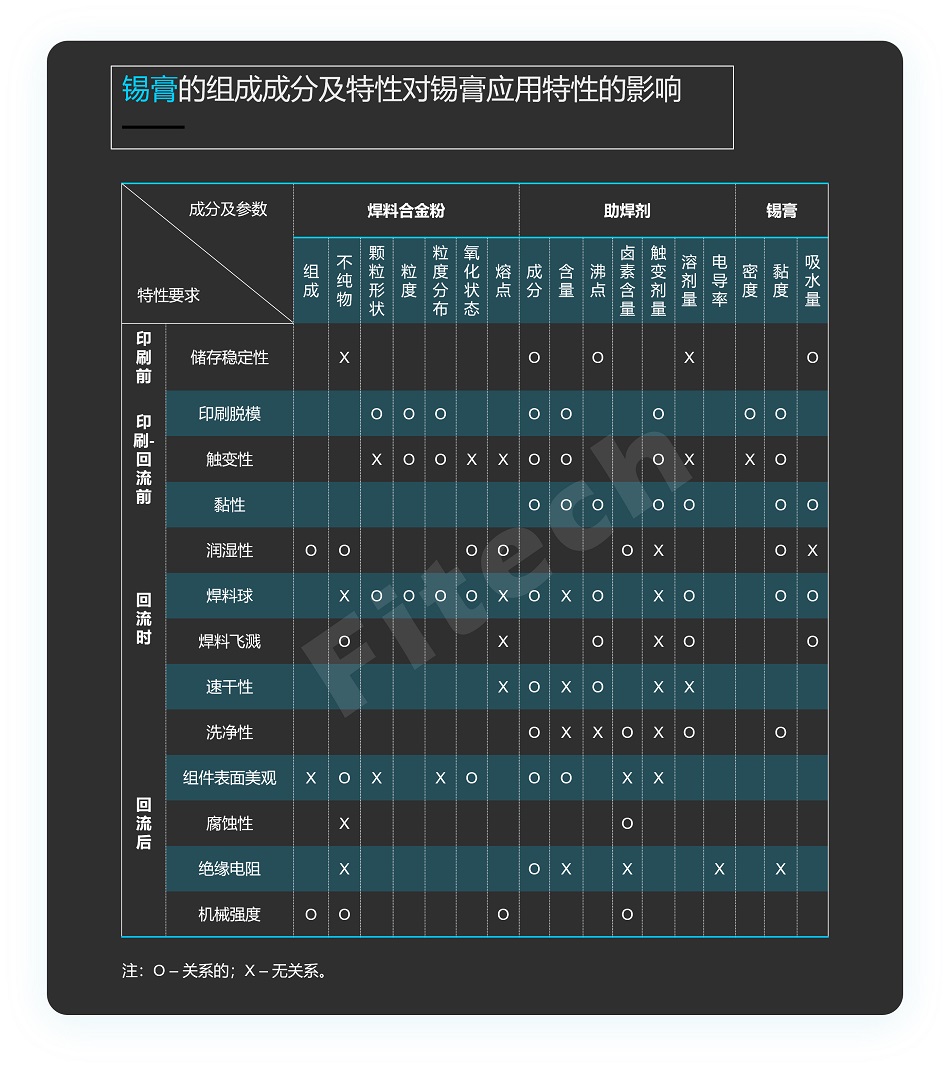

Different components in the solder paste have different effects on the application properties. For example, the melting point of the solder alloy powder has no effect on the thixotropy, but the particle size and size distribution influence the thixotropy of the solder paste. The amount of solvent in the flux has no impact on the thixotropy of the solder paste. However, the flux composition, content, and thixotropy are relevant to the thixotropy. Moreover, the density of the solder paste has no effect on the thixotropy, but the viscosity significantly influences the thixotropy.

At the same time, the same components in the solder paste have different effects on different application characteristics. For example, impurities in solder alloy powder have a negligible effect on the storage stability, solder ball, corrosion, and insulation resistance of solder paste, but have a significant impact on wettability, solder spatter, component surface aesthetics, and mechanical strength.

The following table summarizes the influences of the composition of the solder paste on the applications.

I believe you have a preliminary understanding of the influences of the composition and characteristics of solder paste on the applications. If you want to know more about how to choose solder paste and solder paste performance knowledge, you can follow Fitech, which is a professional soldering solution provider, a national high-tech enterprise.

Back to list

Back to list