What Characteristics Should be Paid Attention to when Choosing a Solder Paste? What does the Thixotropy Mean for Solder Paste Printing?

The performance of lead-free solder pastes greatly affects the soldering effect. It is particularly important to select a lead-free solder paste that matches the production process and product characteristics. The application of lead-free solder pastes describes the performance from various aspects. What characteristics should be paid attention to when choosing a lead-free solder paste? What is the significance of the thixotropy of lead-free solder pastes for printing?

1. What characteristics should be paid attention to when choosing a lead-free solder paste?

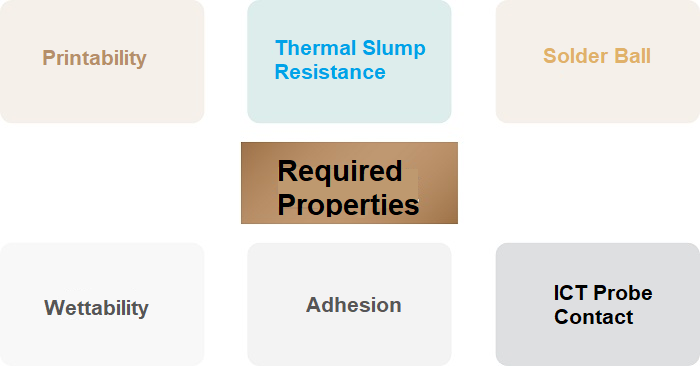

Some of the properties required for lead-free solder pastes are contradictory. For example, in order to maintain printability for a long time, it is necessary to use a high-boiling point solvent, which increases the risk of solder bead formation when reflow soldering. Another example is that it is required to improve the flux activity to obtain good solderability, which may lead to corrosion and reliability problems caused by soldering residue.

Obviously, it is almost impossible to fulfill all feature requirements. Therefore, in the actual selection, it is necessary to understand these contradictory aspects and balance the various requirements in a compromise according to the specific characteristics and uses of the assembled products. As a result, manufacturers can achieve a better comprehensive application effect.

2. What is the thixotropy of solder paste? What is the significance of the thixotropy to ensure the quality of solder paste printing?

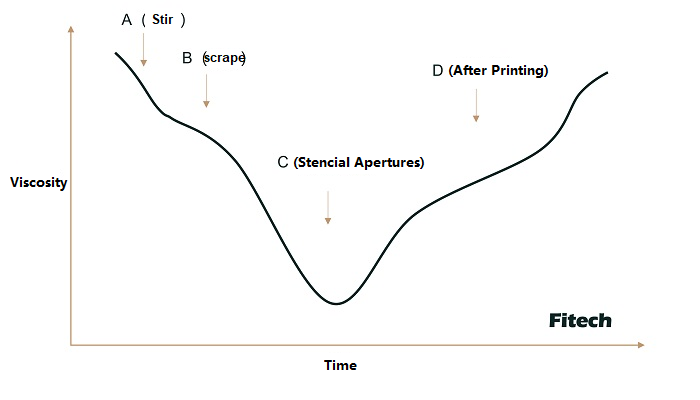

2.1 The thixotropic agent is used to achieve a good thixotropy. The viscosity should drop quickly under the specified shear force and temperature conditions so that the solder paste can pass through the stencil apertures smoothly and has good release performance. As shown in Figure 1.33, after the shear force is removed, the viscosity recovers and maintains at a high value. Obviously, the printing performance of solder paste is largely determined by thixotropy.

2.2 The mixing of the accessories determines the viscosity of the solder paste. Solder paste with high viscosity can form a good printing shape and reduce the phenomenon of collapse. However, solder paste with high viscosity is not easy to pass through the stencil apertures, which can block the apertures and form abnormal solder shapes, leaving hidden dangers for future reflow soldering, such as pseudo soldering, tombstones, etc. Besides, it may produce solder beads and cause short circuits.

2.3 In the high-precision SMT process, it is not only necessary that the solder paste can print a good shape, but also the solder paste can pass through the stencil apertures smoothly. The viscosity of the solder paste should be maintained stable throughout the printing process (4~8h). Otherwise, the reliability of repeated printing cannot be guaranteed. Especially for the printing of fine-pitch SMC/SMD, the solder paste must be fully stirred to ensure that the viscosity satisfies the process to ensure the printing quality.

2.4 Hydrogenated castor oil and carnauba wax can be used as an industrial thixotropic material.

Now, you should have a preliminary understanding of which properties should be paid attention to when choosing a solder paste and learn more about the effect of solder paste thixotropy on solder paste printing performance. If you want to know more about how to select a solder paste and relevant solder paste performance knowledge, You can follow Fitech, which is a national high-tech enterprise specializing in providing ultra-fine solder paste, epoxy solder paste, flux, solder powder, and soldering solutions.

Back to list

Back to list