Improvement of aging and electromigration mechanical properties of Sn57.6Bi0.4Ag solder joints on Au/Ni/Cu pads by adding nano-reinforced tungsten (W)-Shenzhen Fitech

Improved aging and electromigration mechanical properties of Sn57.6Bi0.4Ag solder joints on Au/Ni/Cu pads by adding nano-reinforced tungsten (W)

Formation of (Au,Ni)(Sn,Bi)4 particles during reflow of Au/Ni/Cu pad solder

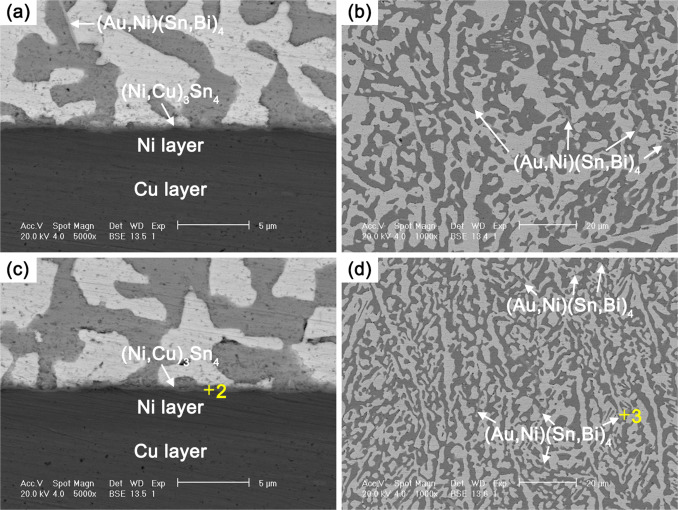

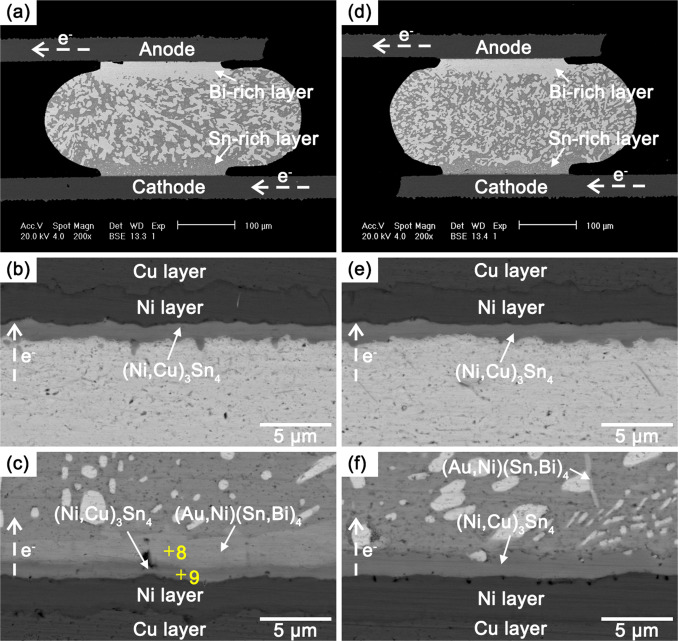

During the formation of the solder joint, the entire Au layer in the Au/Ni/Cu pads rapidly dissolves into the molten solder, resulting in the formation of a large number of (Au,Ni)(Sn,Bi)4 intermetallic compound (IMC) particles in the solder region of the reflow joint. The interfacial IMC areas of the reflow joints are all thin layers of (Ni,Cu)3Sn4.

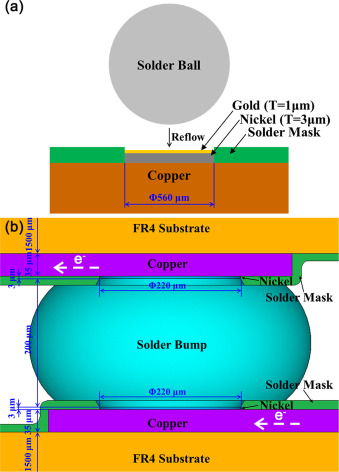

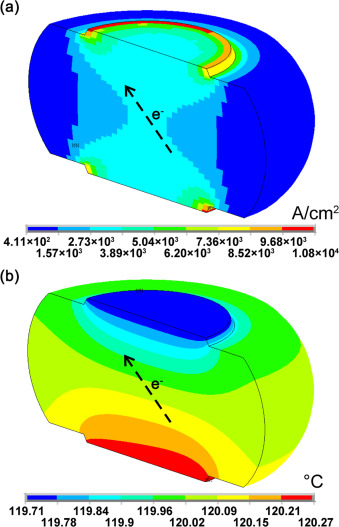

Figure 1. Schematic diagram of (a) the substrate for interfacial reaction analysis and (b) the solder interconnect for electromigration testing (the symbol T refers to the thickness and the arrow marked with the symbol e- indicates the direction of electron flow).

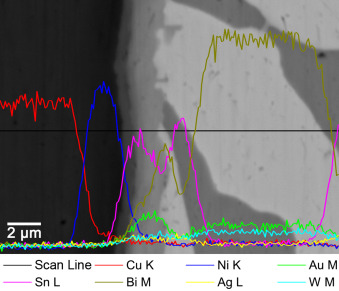

Figure 2. Interfacial microstructure and solder bumps of reflowed (a and b) Sn57.6Bi0.4Ag and (c and d) Sn57.6Bi0.4Ag- w solder joints on Au/Ni/Cu substrates.

Brittle fracture of solder joints during aging

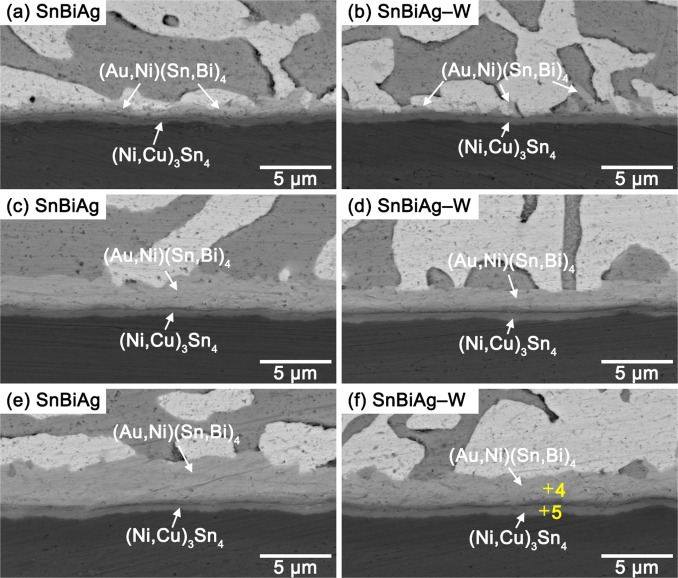

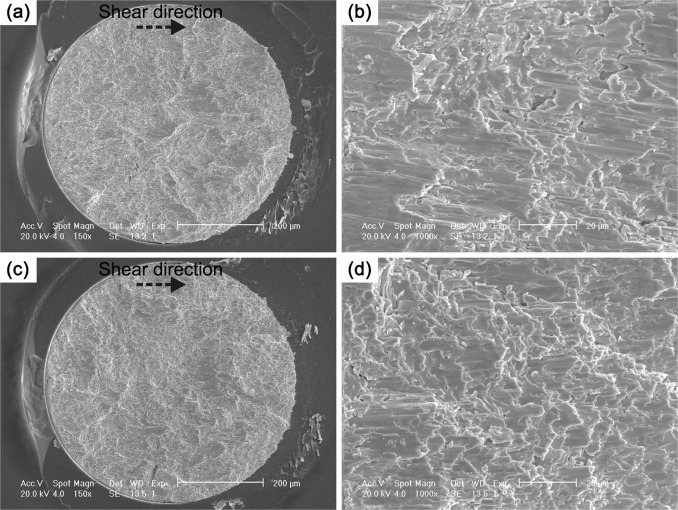

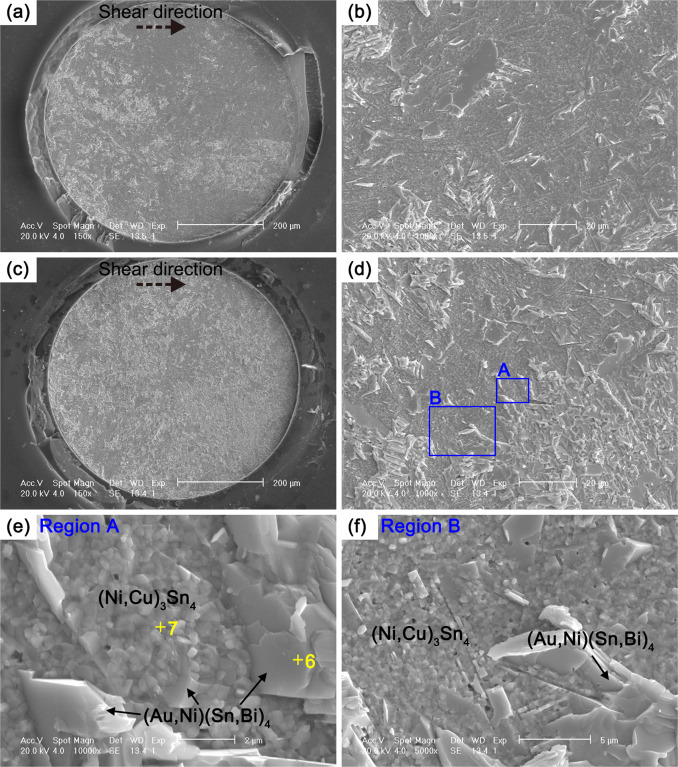

During aging, brittle fracture occurs due to the formation of the interfacial layer (Au,Ni)(Sn,Bi) 4imc. As Au migrates toward the interface, Au accumulates at the bond and forms a thick layer of (Au,Ni)(Sn,Bi) 4 IMC. this accumulation leads to a shift of the fracture path toward the interface IMC region, which transforms into brittle fracture and deterioration of the joint strength due to Au embrittlement. The accumulation of (Au,Ni)(Sn,Bi)4 at the interface of the joint leads to severe degradation of the joint strength and serious reliability problems. The fracture path shifts toward the IMC region of the interface and changes to brittle fracture characteristics. Therefore, it is important to monitor and control the formation of intermetallic compounds during aging, which can lead to brittle fracture and degradation of joint strength.

Figure 3. Interfacial organization of (a, c, e) Sn57.6Bi0.4Ag and (b, d, f) Sn57.6Bi0.4Ag- w solder joints on Au/Ni/Cu substrates after isothermal aging at 100°C for (a, b) 240 h, (c, d) 480 h and (e, f) 720 h.

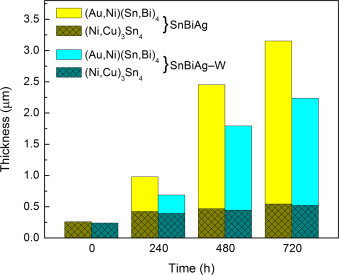

Figure 4. Average thickness of imc at the interface between brazing material and Au/Ni/Cu substrate at different aging times。

Figure 5. EDX-ray scanning micrograph showing the elemental distribution at the SnBiAg-W/Au/Ni/Cu interface after aging at 100°C for 720 h.

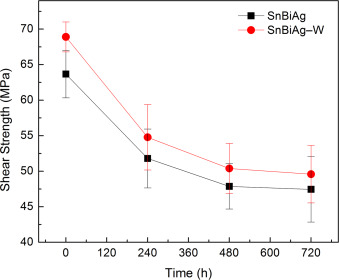

Figure 6. Ball shear strength of SnBiAg and SnBiAg- w solder joints on Au/Ni/Cu pads after different aging times

Figure 7. Enlarged view of the shear fracture of reflowed (a and b) SnBiAg solder joints and (c and d) SnBiAg- w solder joints on Au/Ni/Cu pads.

Figure 8. Magnified view of the shear fracture of (a and b) SnBiAg and (c and d) SnBiAg- w solder joints on Au/Ni/Cu pads after aging at 100°c for 720 h. Highly magnified images of (e) region a and (f) region b.

Figure 9. (a) Current density and (b) temperature distribution in the region of the solder bumps.

The incorporation of W nanoparticles affects the microstructure of the brazing alloy

The addition of W nanoparticles refines the microstructure of the brazing alloy and produces a refinement strengthening mechanism. It reduced the average interfacial spacing between the alternating sn-rich and bi-rich layers, which had a significant refinement effect on the braze matrix. the addition of W nanoparticles also shortened the average distance between the dispersed particles and improved the mechanical properties. Reducing the interlayer phase spacing of the brazing matrix had a significant refinement effect on the brazing matrix. This refinement effect was attributed to the increase in the number of nucleation sites during solidification due to the incorporation of W nanoparticles.

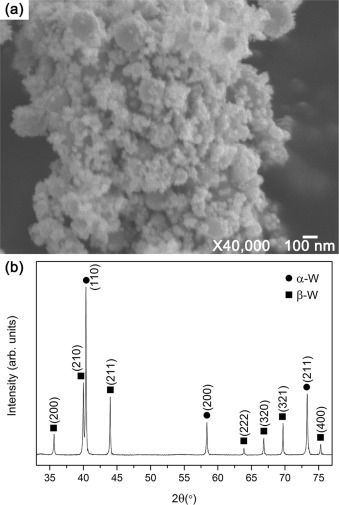

Figure 10. (a) SEM image and (b) XRD spectrum of W nanoparticles.

Figure 11. (a, b, c) Microstructural interconnections of SnBiAg and (d, e, f) SnBiAg- w solders after 720 h of electromigration at 0.5 × 104 a /cm2 and 100 °C, with magnified images of the anode and cathode interfaces.

During the reflow process, the entire Au layer in the Au/Ni/Cu pads rapidly dissolves into the molten solder, forming a large number of (Au,Ni)(Sn,Bi)4 intermetallic compound (IMC) particles in the solder region of the reflow joint. The interfacial IMC regions of the reflow joints were all thin layers of (Ni,Cu)3Sn4. The incorporation of W nanoparticles improved the strength of the reflow joints.

The addition of tungsten (W) nanoparticles to the Au/Ni/Cu pads had an improved effect on the Sn57.6Bi0.4Ag solder joints. the addition of W nanoparticles successfully improved the mechanical properties of the brazing alloy and the microhardness was improved.

References

Yi Li, Kaiming Luo , Adeline B.Y. Lim, Zhong Chen, Fengshun Wu, Y.C. Chan(2016). Improving the mechanical performance of Sn57.6Bi0.4Ag solder joints on Au/Ni/Cu pads during aging and electromigration through the addition of tungsten (W) nanoparticle reinforcement. Materials Science & Engineering, A. Structural Materials: Properties, Misrostructure and Processing, vol. 291-303.

Back to list

Back to list