The selection of solder paste viscosity in the stabbing process of Mini LED backlight chips-Shenzhen Fitech

The selection of solder paste viscosity in the stabbing process of Mini LED backlight chips

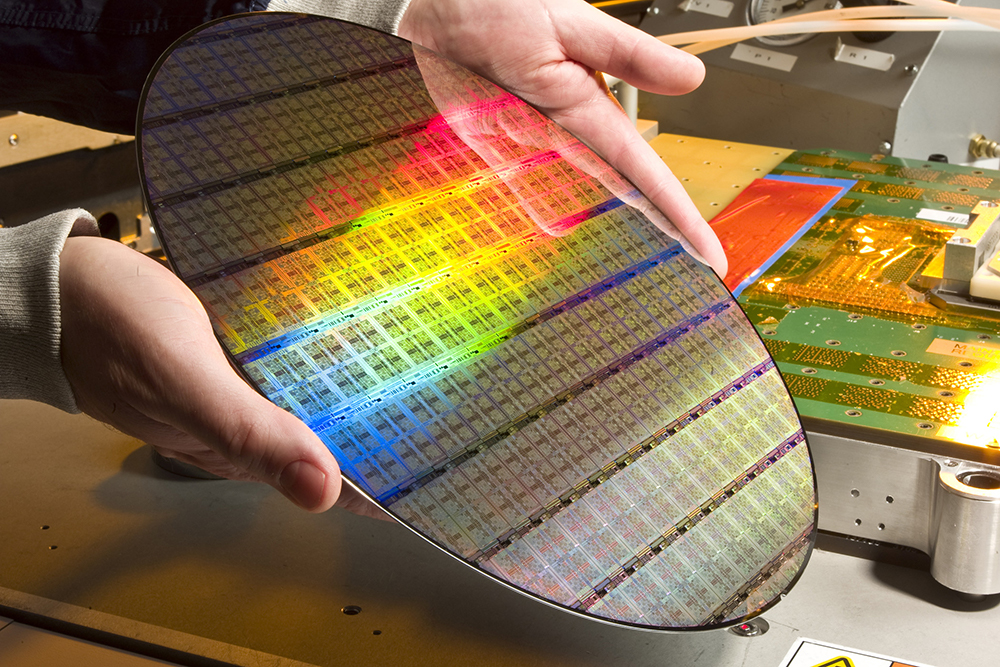

Mini LED chip stabbing transfer process is an important part of the Mini LED manufacturing process. Mini LED chip stabbing transfer process refers to the process of transferring Mini LED chips from the wafer to the substrate. This process requires the use of a technology called stabbing crystal transfer. Stabbing crystal transfer is a technology that pierces the wafer and transfers the chip to another substrate. This technique allows Mini LED chips to be smaller in size, thereby improving the resolution and brightness of Mini LEDs.

First, a Mini LED chip needs to be fabricated on the wafer. mini LED chips are usually made of gallium nitride material, and the manufacturing process requires the use of chemical vapor deposition and photolithography.

Next, a layer of sticky adhesive needs to be applied to the wafer. This layer of adhesive serves to stick the chip to the wafer and prevent it from moving or being damaged during the transfer process.

Then, using a tool called a stabbing needle, the needle is pierced through the wafer to remove the chip from the wafer.

Next, the chip is transferred to another substrate. This substrate can be glass, polyimide or other materials.

Finally, a high-temperature process is required to fix the chip on the substrate and remove the adhesive.

The advantage of the stabbing transfer process is that it enables high-density Mini LED chip manufacturing while ensuring chip quality and stability. Compared to traditional Chip-on-Board technology, Mini LED chips are smaller in size and have higher pixel density, allowing for higher resolution and better color performance.

The Mini LED chip stab transfer process is an important part of the Mini LED manufacturing process, which can help achieve high density, high brightness and high resolution Mini LED displays and backlights.

In the Mini LED chip stabbing transfer process, the role of solder paste is to help hold the Mini LED chip on the substrate for subsequent processing and packaging.

Specifically, solder paste is an adhesive with good conductivity, usually consisting of conductive particles, resin and solvent. In the process of Mini LED chip stabbing transfer, the solder paste is first applied to the substrate and Mini LED chips are placed on it. The paste is then processed at high temperature to melt and fix the Mini LED chip on the substrate.

The conductive properties of the solder paste ensure the electrical signal transfer between the Mini LED chip and the substrate, thus ensuring the proper operation of the Mini LED display and backlight. At the same time, the stickiness and viscosity of the solder paste can help fix the Mini LED chip on the substrate to prevent it from moving or falling off during the subsequent processing.

Therefore, solder paste is a very important material in the Mini LED chip stabbing transfer process. It can improve the reliability and stability of Mini LED chips and ensure the high quality and long life of Mini LED displays and backlights.

In the Mini LED chip stabbing transfer process, there are certain requirements for the adhesion of the solder paste to ensure that the Mini LED chip can be stably adhered to the substrate and avoid moving or falling off during the transfer process.

Specifically, the adhesion of the solder paste should be strong enough to firmly adhere the Mini LED chip to the substrate and not loosen or fall off during the transfer process. At the same time, the adhesion of the solder paste should not be too strong, otherwise it may cause the Mini LED chip to be difficult to remove during the subsequent processing.

In addition, the adhesion of the solder paste should also take into account the nature and surface state of the substrate material. If the surface of the substrate is smooth, a solder paste with a higher adhesion force is required to ensure the stability of the Mini LED chip. If the surface of the substrate is rougher, a solder paste with less adhesion is required for easy removal during the subsequent processing.

Therefore, in the Mini LED chip stabbing transfer process, there are certain requirements for the adhesion of the solder paste, which needs to be selected and adjusted according to the specific situation to ensure the stability and quality of the Mini LED chip.

Shenzhen Fitech co. Ltd. high viscosity solder paste is more suitable for Mini LED stabbing crystal transfer process, welcome to contact us for consultation.

Previous:

Improvement of aging and electromigration mechanical properties of Sn57.6Bi0.4Ag solder joints on Au/Ni/Cu pads by adding nano-reinforced tungsten (W)-Shenzhen FitechNext:

Reliability assessment of ultra-thin 3D-IC packages under the influence of coupled loads from manufacturing process and temperature cycling tests-Shenzhen Fitech

Back to list

Back to list