Conventional tin powder production process - Centrifugal Atomization Method - Shenzhen Fitech

Conventional tin powder production process - Centrifugal Atomization Method

Solder paste solder industry used in the production process of conventional solder powder are mainly centrifugal atomization method, ultrasonic atomization method, etc., each method has its own characteristics.

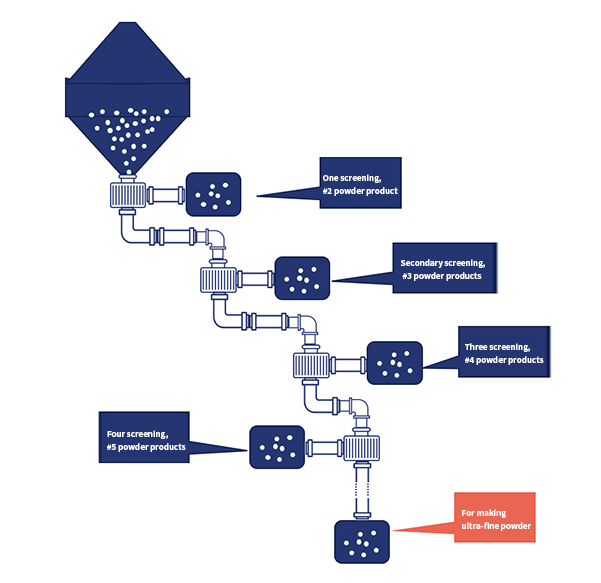

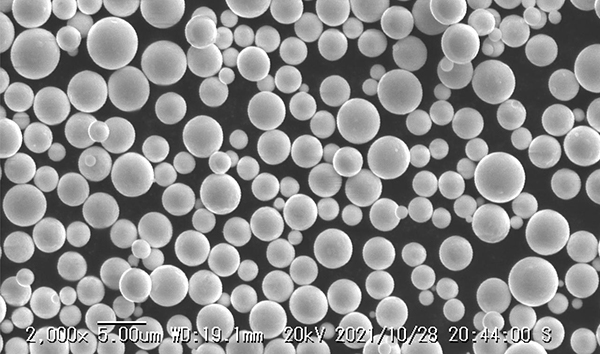

Centrifugal atomization method to produce conventional tin powder is widely used in the industrial world, its main mechanism is to a large closed container filled with inert gas, the general oxygen content is controlled within 200 ppm; a high-speed rotating disc fixed at the top of a high-speed motor, the disc speed adjustable; the composition of qualified molten liquid alloy through the pipe flow (drops) to the rotating disc, the centrifugal force generated by the rotation of the disc will be liquid The centrifugal force generated by the rotation of the disc throws out the liquid solder, driven by the surface tension of the metal droplets, which spheroidizes into small droplets and cools under the inert gas environment to form spherical metal particles, which are gathered at the bottom of the closed container and finally obtain tin powder particles.

In the powder spraying process, the oxygen content control of the closed container is one of the key parameters, followed by the problem of matching the disc speed with the flow of liquid solder. The diameter of the closed container determines the limit speed of the disc and the capacity of the tin powder - the faster the speed, the greater the centrifugal force, and the greater the probability of the uncured liquid metal mass hitting the container wall to form a tin cake. The higher the oxygen content in the closed container, the more severely the formed tin powder is oxidized as well as affecting the surface tension of the droplets are prone to form non-spherical particles; the finer the tin powder particles, the larger the surface area per unit mass of powder, the higher the tin powder oxygen content.

The centrifugal atomization process is mature, its output is large, and the obtained tin powder particle size range is wide, from Type3, Type4 to Type5, Type6 tin powder have a certain production rate. Centrifugal atomization process in the process of curing tin powder by gravity, tin powder has a tendency to be water droplets, thus affecting the true roundness of the powder, which requires liquid solder thrown out as soon as possible after curing to reduce the impact of gravity. The centrifugal atomization method is now mainly used for the manufacture of conventional tin powders of Type 2 to Type 5.

Back to list

Back to list