Effect of adding Cu6Sn5 nanoparticles on the structure and properties of SnBi brazing alloys-Shenzhen Fitech

Effect of adding Cu6Sn5 nanoparticles on the structure and properties of SnBi brazing alloys

3.1

The importance of tin-based lead-free solders in the electronics industry is coming to the fore as electronic devices become more common in everyday life. In order to prevent damage to electronic equipment at high soldering temperatures, research into low temperature soldering and low melting point solders is being carried out extensively.

Sn42Bi58(Ag) solder has high tensile strength and a low melting point, making it a promising lead-free solder. However, some properties of the alloy of Sn42Bi58 solder still need to be enhanced.

Enhancing brazing alloys with particles is an effective way to improve the properties of brazing alloys. The three types of particles used for enhancement are: metallic particles, oxide particles and nanoparticles of intermetallic compounds (IMCs).Cu6Sn5 nanoparticles are an effective low temperature sintering material and the effects of incorporation of Cu6Sn5 nanoparticles on brazing alloy organisation, tensile properties, creep behaviour and corrosion resistance are summarised here.

Figure 1. Scanning electron microscopy images of (a) Sn58Bi powder and (b) Cu6Sn5 nanoparticles.

3.2 Analysis of the effect of different concentrations of Cu6Sn5 nanoparticles on the microstructure of SnBi brazing materials

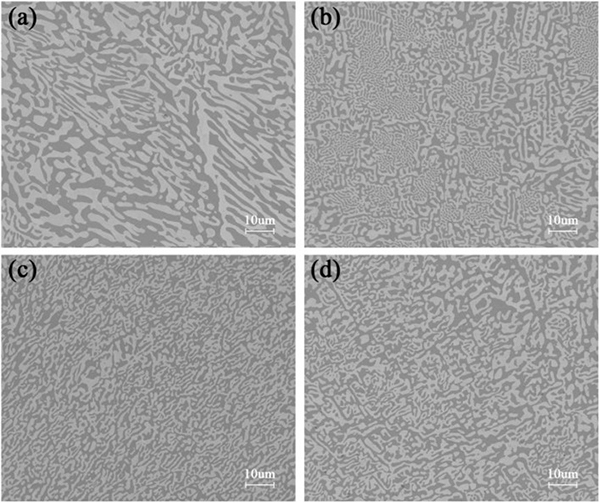

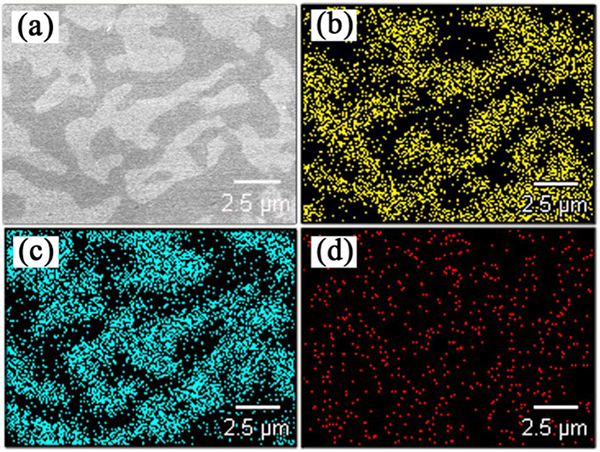

Backscattered electron (BSE) images show that the microstructure of the solder joint becomes finer after the addition of Cu6Sn5 due to non-homogeneous nucleation. When the concentration of Cu6Sn5 reaches 0.1 wt%, the organisation becomes rough again due to agglomeration of nanoparticles. Energy spectrometer (EDS) analysis showed that the Cu element was evenly distributed in the bi-rich and sn-rich phases, unlike SnBi with Cu nanoparticles, where Cu tended to be dispersed in the sn-rich phase. This is because Cu6Sn5 nanoparticles do not react with tin in the composite solder of this work.

Figure 2. BSE images of (a) SnBi, (b) SnBi-0.03 cu6sn5, (c) SnBi-0.05 cu6sn5 and (d) SnBi-0.1 cu6sn5 brazing material microstructures.

Figure 3. Elemental mapping of SnBi-0.05Cu6Sn5 solder: (a) (b) secondary electron (SE) images and EDS mapping of (b) Sn, (c) Bi and (d) Cu.

3.3 Tensile properties of Cu6Sn5 nanoparticle microalloyed SnBi braze

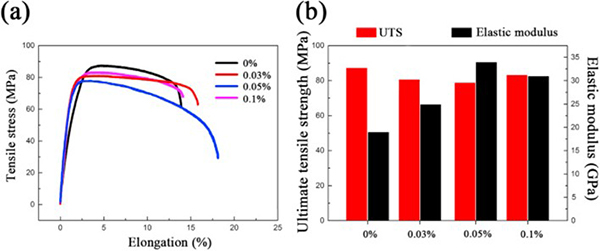

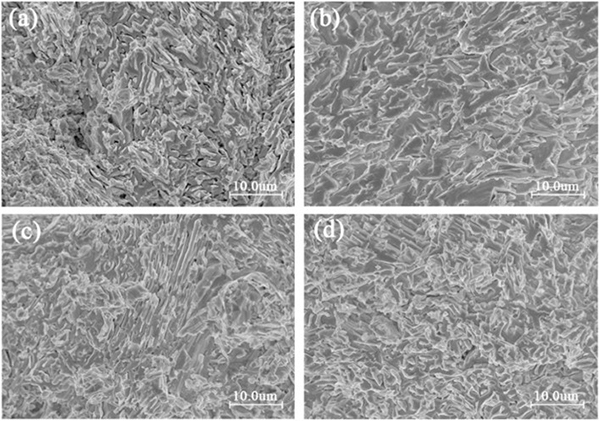

The addition of nanoparticles weakened the bond between the Cu6Sn5 IMC nanoparticles and the SnBi matrix, resulting in a lower ultimate tensile strength (UTS). However, the UTS of the composite braze was still higher than that of the SnAgCu and SnAg brazes. The addition of nanoparticles increased the elongation, with the maximum elongation observed at 0.05 wt% nanoparticle addition. The modulus of elasticity increased continuously with increasing nanoparticle concentration, reaching a maximum at 0.05 wt%. the presence of Cu6Sn5 nanoparticles also reduced the porosity and thus increased the modulus of elasticity. SE images of tensile fractures show that the addition of nanoparticles shifts the brittle SnBi solder towards being more ductile. However, too many (0.1 wt%) nanoparticles reduce the improved effect of Cu6Sn5 imc nanoparticles due to aggregation, resulting in lower elongation.

Figure 4. (a) Tensile stress-elongation curves of SnBi-xCu6Sn5 (x = 0, 0.03, 0.05, 0.1) solder sheets; (b) variation of ultimate tensile strength and elastic modulus of specimens with different Cu6Sn5 concentrations.

Figure 5. SE images of tensile fracture of (a) SnBi, (b) SnBi-0.03 cu6sn5, (c) SnBi-0.05 cu6sn5 and (d) SnBi-0.1 cu6sn5 solder sheets.

3.4 Results of creep behaviour measured by nanoindentation test

A peak load of 20 mN was held for 30 s to demonstrate the creep behaviour of the different specimens. The penetration depth decreased with increasing Cu6Sn5 concentration and the creep resistance gradually increased. The addition of Cu6Sn5 nanoparticles resulted in a significant improvement in the creep deformation of the SnBi braze, with the best creep resistance for the 0.05% and 0.1% mass percentage composite brazes. The creep strain rates of all composite braze materials were lower than those of the pure braze materials. With the addition of Cu6Sn5 nanoparticles, the main creep mechanism changed from dislocation creep to grain boundary slip, resulting in a lower final creep strain rate.

Figure 6. (a) Load-penetration curves for indentation tests at different nanoparticle concentrations, (b) creep process of specimens at a peak load of 20 mN for 30 s, (c) variation of creep strain rate at different Cu6Sn5 nanoparticle mass percentages, and (d) creep stress indices of various composite brazing alloys.

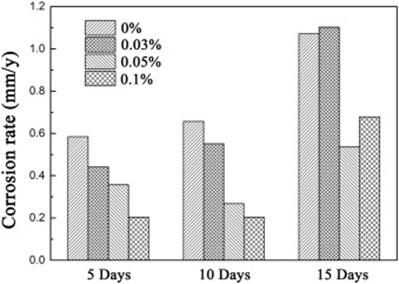

3.5 Corrosion resistance of composite solder samples with different Cu6Sn5 nanoparticle concentrations

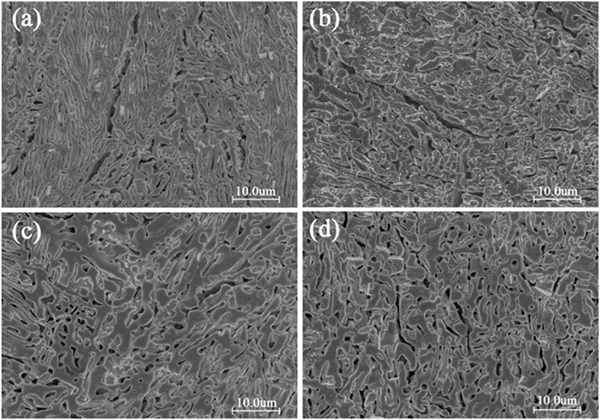

Corrosion rates were calculated after 5, 10 and 15 days of testing. The results showed that the addition of nanoparticles improved the corrosion resistance and reduced the increase in corrosion rate. Microstructural analysis showed that the composite brazing material produced more micro and nano corrosion resistant particles which acted as a corrosion barrier and reduced the pitting tendency of the brazing substrate. The addition of Cu6Sn5 nanoparticles was best for 0.05% corrosion resistance.

Figure 7. Comparison of corrosion rates of composite solders with different Cu6Sn5 nanoparticle concentrations.

Figure 8. SE images of (a) SnBi, (b) SnBi-0.03 cu6sn5, (c) SnBi-0.05 cu6sn5 and (d) SnBi-0.1 cu6sn5 solder surfaces after 15 days of etching.

Summary

Improved SnBi brazing alloy properties with 10 nm Cu6Sn5 nanoparticles. In tests, the best soldering performance was achieved with 0.05% Cu6Sn5 nanoparticles. the addition of Cu6Sn5 nanoparticles refined the microstructure of the SnBi brazing compound. The tensile properties of the composites changed from brittle to ductile compared to the pure specimens. Nanoindentation tests showed that the creep resistance of the SnBi-Cu6Sn5 samples was enhanced by a shift in the creep mechanism. In corrosion experiments, samples containing nanoparticles exhibited lower corrosion rates. This intermetallic compound nanoparticle enhancement will provide new insights into solder microalloying.

References

Effects of nanoscale Cu6Sn5 particles addition on microstructure and properties of SnBi solder alloys. Nanotechnology Weekly. PP.192.

Back to list

Back to list