Shenzhen Fitech Knowledge-Solder Paste Alloy Composition

Shenzhen Fitech Knowledge: Solder Paste Alloy Composition

The bulk of the solder paste is composed of alloy and flux. It is well known that the alloy compositions can be various, so how are the alloy compositions of the mainstream solder pastes determined? The scientists summarized experimental data and created the phase diagrams based on the different metal ratios and the alloy properties. We need to use the phase diagrams to confirm the solder paste alloy compositions. The more types of metals contain, the more difficult to make the phase diagrams. Therefore, binary and ternary alloys are most widely used in the packaging solder paste industry. The relationship between the metal ratio and the melting and curing temperatures can be clearly obtained from the phase diagrams.

Eutectic solder paste

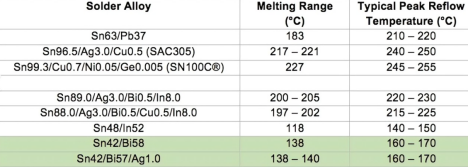

Generally speaking, the temperature of alloys will be lower than that of pure metals because the force between the pure metal atom is relatively stable, and the metal atoms are arranged in an orderly manner. However, adding other metals will increase the force and affect the internal arrangement, changing the internal energy and temperature. When reaching the lowest melting point temperature at a specific metal ratio, the alloy can be defined as eutectic. Eutectic lead-free solder pastes are widely used. Due to the approachable low melting temperature, eutectic solder pastes can achieve low-temperature reflow soldering. For example, Sn42Bi58 is a eutectic lead-free solder paste with a melting point of 138°C.

Table 1. Alloy composition and melting points of different solder pastes.

The choice of alloy composition needs to be determined according to the soldering furnace temperature of the packaging manufacturers. Solder paste products are customized according to the manufacturer's reflow profiles. In addition, different alloy types, such as tin-bismuth and tin-silver-copper combinations, should be selected according to the requirements for thermal conductivity, electrical conductivity, and mechanical strength. The lead-free solder powder formulations typically contain tiny amounts of silver since the appropriate silver content enhances the solder joint conductivity and mechanical strength. Moreover, the addition of silver can improve the wettability of solder pastes, allowing the solders to sufficiently spread on the pads after heating and form bright and full solder joints. Therefore, tin-silver-copper alloys are more common than eutectic tin-copper alloys.

Fitech is a world-leading provider of microelectronics and semiconductor packaging materials solutions. Fitech’s solder paste, epoxy solder paste, and solder powder have good wetting effects, narrow particle size distribution, and outstanding reliability after soldering. Welcome to Fitech’s official website for more information.

Back to list

Back to list