Shenzhen Fitech Knowledge: Solder Paste Temperature Properties

CN: https://www.szfitech.com/

EN: https://en.szfitech.com/

Shenzhen Fitech Knowledge: Solder Paste Temperature Properties

The development of the semiconductor industry is inseparable from the iteration of chip technology. Chip size is getting smaller and smaller as technology advances. Chip miniaturization requires fine pitches, resulting in a complex die bond process. The chips are placed in the designated area of the package substrates through an adhesive such as solder paste to form a thermal path or an electrical path. One of the important criteria for choosing the appropriate solder paste is temperature. This article will introduce the temperature properties of package solder paste.

1. Soldering temperature selection

The bulk of solder paste is composed of alloy and flux. The properties of solder paste greatly influence the yield of the die bond. Different manufacturers have specific requirements for bonding temperatures. For example, the solder pastes used for low-temperature components and power devices are different. Therefore, the solder pastes should be able to adapt to various packaging scenarios. The factor determining the solder paste melting and solidification temperatures is alloy composition. The melting temperature of the alloy can be obtained by generating the corresponding phase diagram.

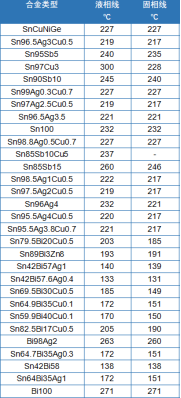

Eutectic tin-lead solder pastes were commonly used before leaded solders were banned. With the accelerated progress of replacing leaded solder pastes with lead-free solder pastes, tin-silver-copper and tin-bismuth alloys are welcomed, among which SnAg3Cu0.5 (melting point 217℃-219℃) and Sn42Bi58 (melting point 138℃) are especially popular. The melting points of some lead-free solder pastes are shown in the figure below.

Figure 1. Liquidus and solidus of lead-free solder paste.

2. The importance of proper reflow temperature

Reflow soldering is one of the important steps in the packaging process. Solder paste melts and solidifies during reflow. Solder paste melts and wets the pads after reaching the melting point temperature. The choice of temperature has a great influence on the wetting effect. Usually, the peak reflow temperature needs to be about 25°C-45°C higher than the melting point of the solder paste. A slightly higher reflow temperature can fully melt the solder paste and allow it to cover the pads. However, the temperature should not be too high. Otherwise, it will accelerate the growth of intermetallic compounds and weaken the reliability of solder joints. The specific reflow temperature needs to be adjusted according to the actual situation of the manufacturers.

Figure 2. A jar of eutectic Sn42Bi58 solder paste.

Fitech is committed to the development and production of packaging solder paste. The lead-free solder products include tin-silver-copper and tin-bismuth combinations. The products can be used in various packaging scenarios to produce highly reliable solder joints. Welcome to consult.

Back to list

Back to list