The Effects of Solder Paste Alloy Proportion on Bumps

The Effects of Solder Paste Alloy Proportion on Bumps

As the number of I/Os increases, the high demand for tiny electronic devices with higher performance requirements makes integrated circuits (ICs) more complex, leading to packaging technologies innovation. As component sizes decrease, the interconnect structure of IC chips to pads or printed circuit boards requires for solder ball grid arrays to reduce bump pitch and size. Lead-free solder paste is widely used in packaging and is currently an indispensable material in the solder bump process. Mainstream lead-free solder pastes include tin-silver-copper and tin-bismuth solder pastes. The properties of lead-free solder pastes can be affected by the formulation, such as flux and alloy proportions, which in turn affect the effect of bumping.

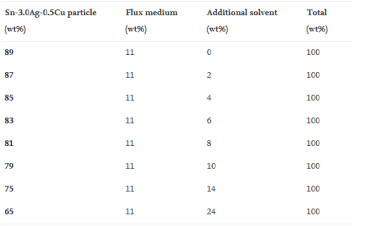

Solder paste is composed of alloy particles, flux medium, and additional solvent. Different components represent different formulations. Son et al. (2018) used SAC305 solder paste with different formulations for reverse offset printing tests. The solder paste was printed on the pads through a roller blanket to make bumps. The composition of the testing solder paste is shown in Figure 1.

Figure 1. Testing solder paste composition.

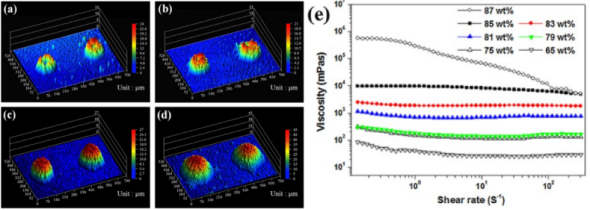

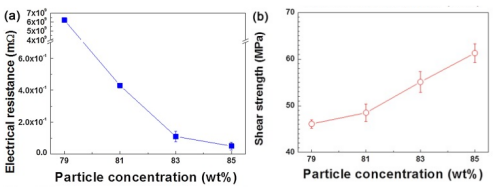

Solder alloy particle ratio has a large effect on bump appearance and viscosity. As shown in Fig. 2, the bumps obtained by printing the solder paste with 79wt% alloy particles were uneven in shape and rough at the top, resulting in poor solderability. As the alloy content increased to 85wt%, the thickness of the printed bumps gradually increased. The bumps are uniformly hemispherical and have a smoother top surface. In addition, when the alloy composition reaches 87wt%, the obvious shear thinning characteristic can be observed, which largely determines the smooth deposit of the solder paste through the stencil apertures. It can be seen from Figure 3 that with the increase of the solder alloy composition, the bump resistance decreases significantly, and the shear strength increases rapidly, which means that the electrical conductivity and mechanical properties of the solder joints have been effectively improved.

Figure 2. 3D image of solder bumps and viscosity variation, (a) alloy 79wt%, (b) alloy 91wt%, (c) alloy 83wt%, (d) alloy 85wt%, (e) viscosity variation (Son et al., 2018).

Figure 3. Electrical resistance and shear strength of SAC305 solder paste (Son et al., 2018).

Undoubtedly, the alloy proportion needs to be adjusted according to the different processes. Excessively high alloy particle proportion is likely to cause poor solder paste wettability, thereby reducing the soldering effect. Fitech is committed to producing high-quality lead-free ultra-fine solder paste. The products are suitable for various processes, such as printing, dispensing, etc. The solder paste has good rheology and high post-soldering reliability. Welcome to consult and understand more information.

Reference

Son, M.J., Kim, M., Lee, T.M., Kim, J., Lee, H.J., & Kim, I. (2018), “Mechanical and electrical properties of reverse-offset printed Sn-Ag-Cu solder bumps”, Journal of Material Processing Technology, vol.259, pp.126-133.

Back to list

Back to list